JFcustom

Sr Member

Hi,

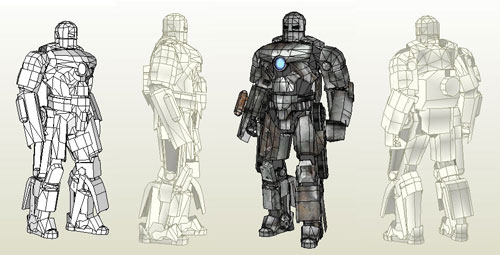

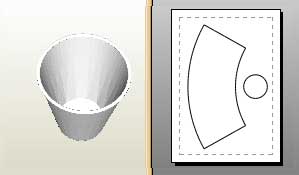

After a basic but effective five-days-built Iron Man Mark IV, I wanted to improve and share my speed-building technics to allow everyone having kids and a full-time job to be still able to build a full foam suit in far less than a month. And it begins with releasing some suitable *.pdo files.

By suitable I don't mean at all that the other guys who unfold for foam should better drop their work right through the gogs. Not at all. By suitable I mean that the templates below can only be used under certain restriction of material :

at first you must use some foam mats, or foam roll, or whatever else, much larger than a common paper sheet. Then, you may use some cheap foam, because these templates generate a impressive amount of waste. And at last, the more your foam is flexible, the more easy will be your build. This point depends mainly of the thickness of this foam. I would recommend somewhere between 5 and 10mm. I use 7mm.

The way I unfold allows each curve and bulge-shaped effect to be obtained without the need of a heat gun. It has occurred that these templates work fairly well with corrugated cardboard, and also, through proper tweaking, for aluminium panels.

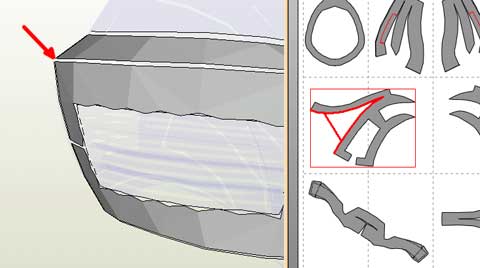

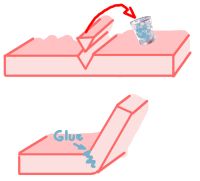

But if you plan to use some sheets of foam of one square foot, or one inch thick, or almost unbendable, you won't be able to use these templates. About flexibility, here's a quick illustration of what you'll often have to do with your foam (yea I know, it's paper on the photos, but it's only an illustration) :

This thread aims to gather the models I've unfolded with both "foam" and "speed-build" in mind, as well as the tips that come along with the files. You may notice that some esthetical details are often missing, details like grids, holes, screws, notches, indentations... They have been removed from the templates to build faster, and are called to be added on your own once the armor part is built. Every missing detail can always be implemented afterward. The final shape remains unchanged, you won’t have any ‘more angular’ nor ‘more inflated-like’ body parts than with other files.

At the end we obtain some pepakura files with less and larger pieces, foam flaps for stronger and discrete overlap gluing, and in one word a better compatibility with foam shapeability.

Well at least I assume it is...

__________________________________________________

The files below are, and will remain, unlocked and shared freely for all to download and use, since they are used in the evident respect of legality. Do not go thinking so far that I'm plenty of buckets full of free time to work on these files, because it's not the truth at all. And in order to prevent my wife from strangling me, I promised to add this link.

__________________________________________________

For Iron Man mark 4 and 6 I robbed Robo3687's files, I stole the mark VII in DarkSide501st's pockets, and Dancin_fool has modeled the mark III. A big thank to you, without your work all of us would still keep saving the world in underpants.

If it happens you find here a(n other) file that is not fully credited, please contact me.

All male suits are default scaled for a 6' guy.

Here we are :

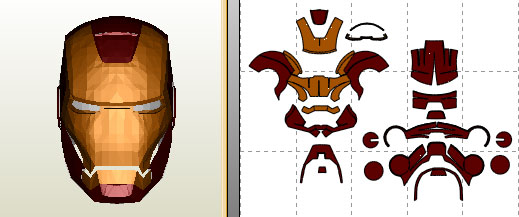

robo3687's Iron Man Mark 4/6 - unfold for foam by JFcustom.rar

I've colorized here where to connect the parts together :

And here, how I connected collar plates to the top of the back/chest :

anyway, it's the way I did... The result is a one-piece torso that you put on just like a T-shirt.

Iron Man mark7 by Karol Siemieniago - minor edit and foam unfold JFcustom.rar

Incredibly both movie-looking and simple to build.

DarkSide501st's Iron Man Mark VII - v1.0 - unfold for foam by JFcustom.

I have to reedit some files from the beginning for this suit to be doubt-proof and fully workable. I'll should have join a readme file for this one, because I think that some tips need to be explain before you drive straight against the wall...

Note that gloves, brace, collar, collar plate, and neck are missing from MkVII package. You can pick them from Mk2, 3 or 4.

EyeofSauron's Iron Man Extremis - unfold for foam by JFcustom.rar

Iron Man Extremis v2 - foam unfold JFcustom.rar

classic iron man provided by EyeOfSauron - foam unfold JFcustom.rar

Marvel, Zabanna, and BenStreeper's Iron Man Ultimate V2 - unfold for foam by JFcustom.

Link to the rar file in the post by CSM-101 (me) time stamped 02-18-2013, 02:25 AM

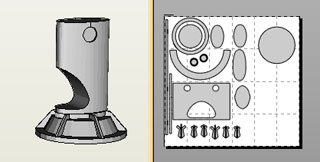

Tribes Ascend - heavy armor - JFcustom foam files.rar

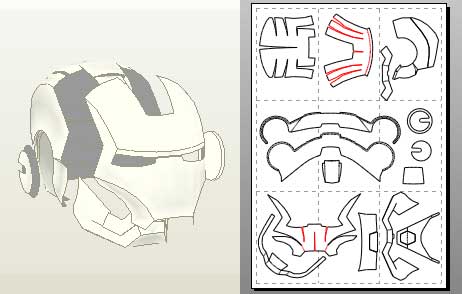

Robo3687's War Machine - unfold for foam by JFcustom.

All included but heavy weapons. Helmet design by Stark1138.

Iron Patriot by Jackieisrockin - foam unfold JFcustom.rar

Briareos by C2/Lord Harnor/Dung0Beetle/JFcustom - foam unfold JFcustom.rar

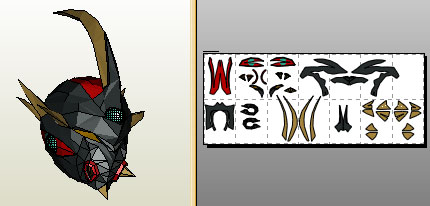

Guyver the Bioboosted Armor - FOAM edit and unfold JFcustom.rar

At last. Full from head to toes. The 6 tubes on the sides of the chest, as well as the spheres on the helmet are left to be freehanded.

Predator - foam edit & unfold JFcustom.rar

Cyberman - foam unfold JFcustom.rar

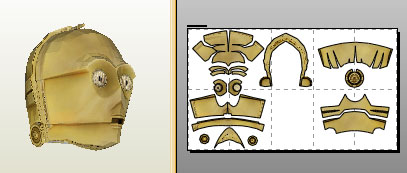

c3po.rar

BSD's Rex PhaseII - foam ufold JFcustom.rar

Dancin_Fool's Iron Man MkII/MkIII - unfold for foam by JFcustom.

To go at simplest, every detail missing from the original model (grids, holes, screws, notches, indentations...) will have to be added manualy afterward by directly sculpting them into the foam. Please refer to Dancin_Fool's files or included ref pics.

Vanquish ARS provided by Tumbucu1 - unfold for foam by JFcustom.

A huge painting work to make this one look good, but I think it can worth the time spent. The files in the rar may be updated without warning during the coming days.

Thor - unfold for foam by JFcustom.

Helmet model by Dung0beetle, I don't know who created the other parts...

Pepper Potts Rescue Armor - foam edit JFcustom.rar

Credits :

Back and torso modeled by Eirth @405th

Arms from a Halo mkVI modeled by Robogenesis @405th

Helmet is IM comic version from EyeOfSauron

All other parts provided by EyeOfSauron's Extremis suit.

All of these post-edited to fit a woman's body.

An overview pic here.

The suit is scaled for a 1m70 heigh girl. (ie 5'7")

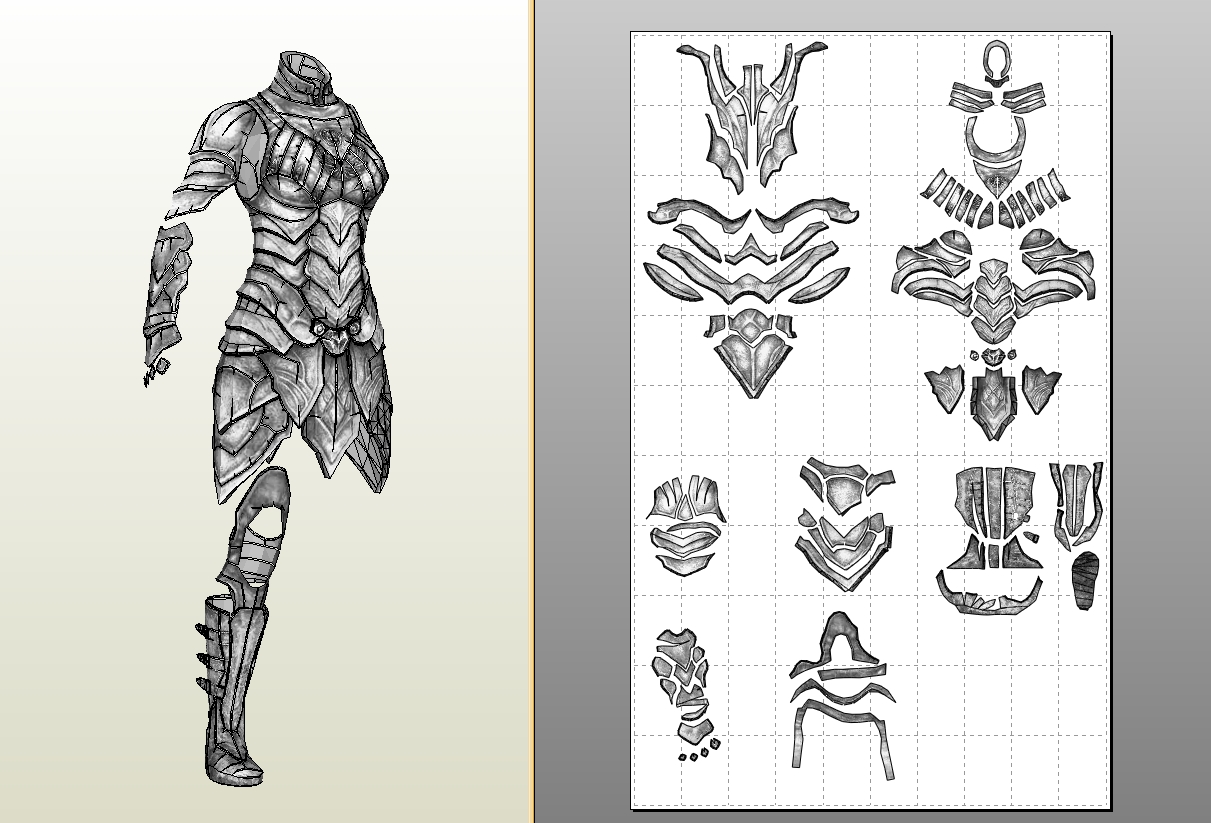

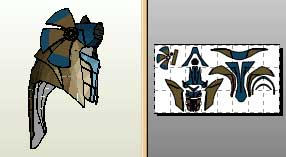

Nightingale female suit - The Elder Scrolls V - Skyrim - foam unfold JFcustom.rar

Skyrim - Female Daedric armor - foam unfold.rar

Snow White Armor - model and foam unfold JFcustom.rar

Iron Man MK1 - cave suit.rar

spacemarine - foam unfold JFcustom.rar

spacemarine - foam unfold JFcustom.rar

Laputa's Soldier - 7ft tall display - foam unfold JFcustom.rar

Laputa's Soldier - 7ft tall display - foam unfold JFcustom.rar

S-CRY-ed Kasuma's arm - foam unfold JFcustom.pdo

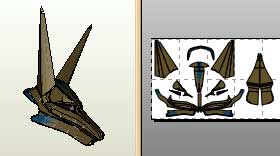

Rhinoc's predator biohelmet - foam unfold JFcustom.pdo

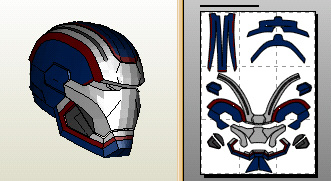

Darkside501st's iron patriot helmet - foam unfold JFcustom.pdo

TDK cowl - foam unfold JFcustom.pdo

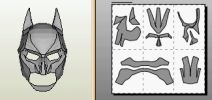

Batman Arkham cowl - foam unfold JFcustom.pdo

Arkham Origins Batman cowl - foam unfold JFcustom.pdo

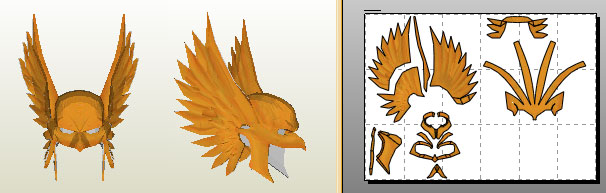

DCU - Hawkman cowl - foam unfold JFcustom.pdo

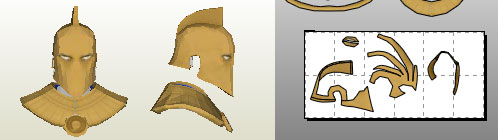

DCU - Fate helmet - foam unfold JFcustom.pdo

DCU - Hawkgirl cowl - foam unfold JFcustom.pdo

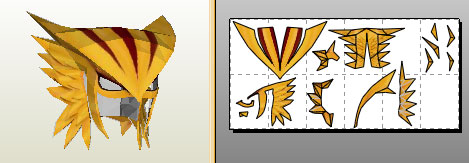

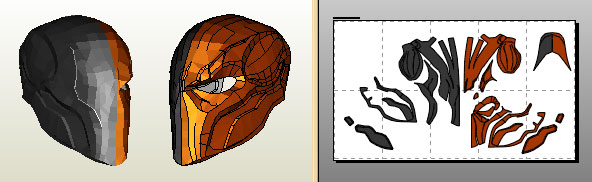

JFcustom's Arkham-Deathstroke.pdo

Injustice - Deathstroke Helmet - JFC foam.pdo

Guardians of the Galaxy - StarLord helmet.pdo - model and foam unfold JFcustom.pdo

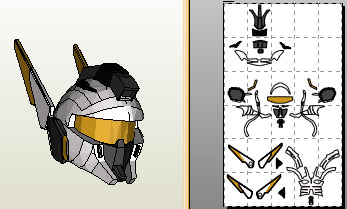

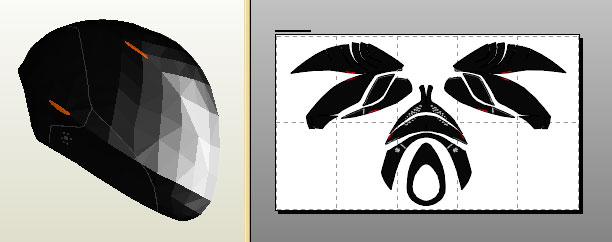

Titanfall pilot helmet 1 - JFC foam.pdo

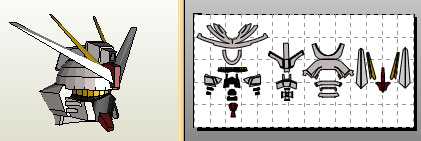

freedom gundam helmet - foam unfold JFcustom.pdo

Landmate helmet - foam unfold JFcustom.pdo

classic iron man helmet by EyeofSauron - foam unfold JFcustom.pdo

omarbou1-ironmanmark7v2helmet-jfcfoam.pdo

Iron Patriot by Jackieisrockin - 13 - helmet - foam unfold JFcustom.pdo

Multi-hero cowl - Blue Beetle pattern - model and foam unfold JFcustom.pdo

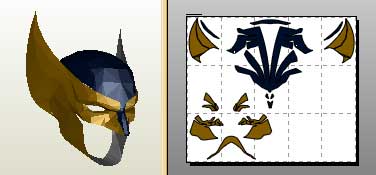

Wolverine cowl - foam unfold JFcustom

Rinzler helmet - foam unfold JFcustom.pdo

Obito war mask.pdo

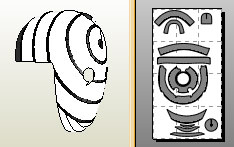

Embo hat-shield.pdo

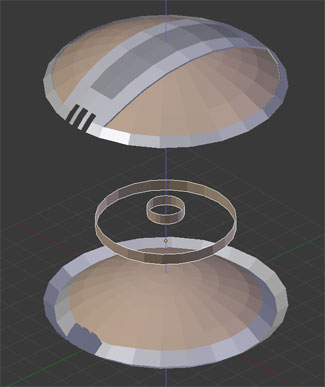

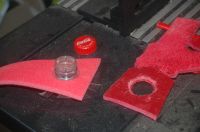

About the thickness, you'll just have to add two or three circles of foam between the two layers to make it keep its shape, just like that :

c3po-head.pdo

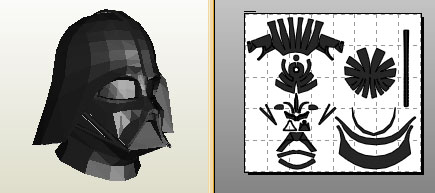

Dark Vader helmet - foam unfold JFcustom.pdo

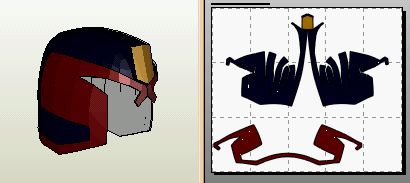

Dredd 2012 helmet by Dung0Beetle and Blaxmyth - Foam edit and unfold JFcustom.pdo

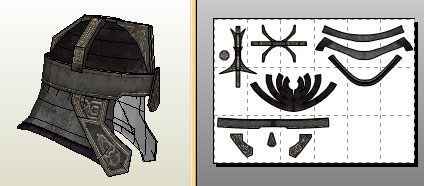

Dwarf helmet.pdo

Jango FETT helmet - foam unfold JFcustom.rar

Rocketeer helmet - edit and foam unfold JFcustom.pdo

Dr.Fate helmet - foam unfold JFcustom.pdo

Guyver 3 helmet - foam unfold JFcustom.pdo

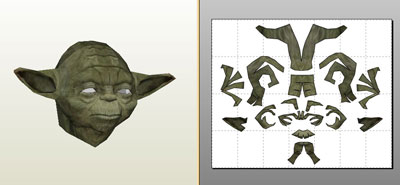

Yoda's head.rar

Dung0beetle's Spaceballs Dark Helmet - foam unfold JFcustom.pdo

and the little prop that comes along :

Spaceballs - Dark Helmet's coffee cup.rar

BTTF Mr. Fusion - JFC foam.pdo

Mind the scale before printing.

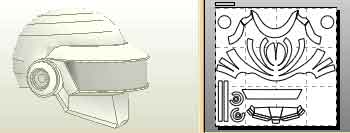

Daft Punk - Cama900's GuyMan Helmet - Foam edit and unfold JFcustom.pdo

Daft Punk - Dung0Beetle's Thomas Helmet - Foam edit and unfold JFcustom.pdo

sg - shoulder cowl base.pdo

sg - woof.pdo

sg - chirp.pdo

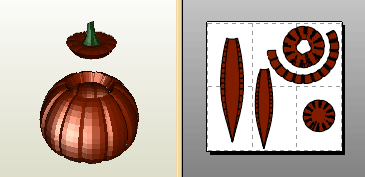

foam-pumpkin.pdo

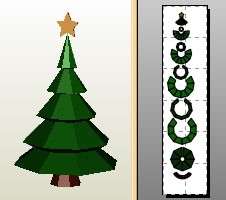

christmastree - foam unfold JFcustom.pdo

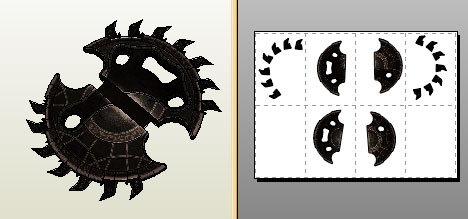

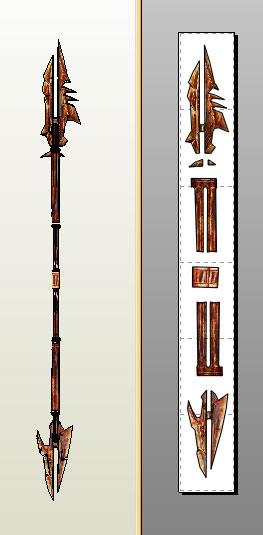

Few accessories that come along with the Predator suit :

weapons :

predator-battledisc.pdo

spear.pdo

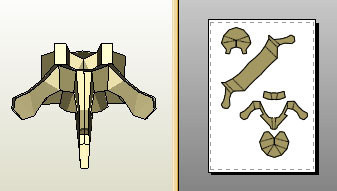

and trophys :

human vertebra.pdo

Build several ones with a slightly changing scale to get a realistic full spine.

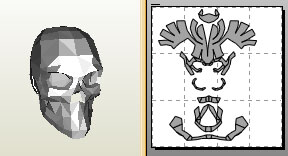

(almost) human skull.pdo

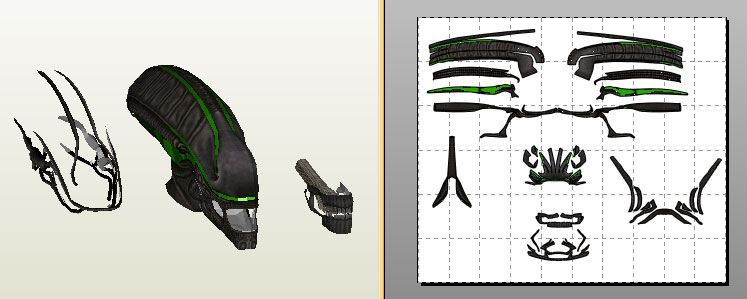

Alien head - provided by Movieman - foam unfold JFcustom

And to both solve the issue of the lower eyes that happen to bulge way out, as described here, and improve the details of the ears area, here's an enhanced unfolding version of Sharkhead's Iron Man Helmet :

Sharkhead7854-ironman-helmet-foam-unfold-by-JFcustom.pdo

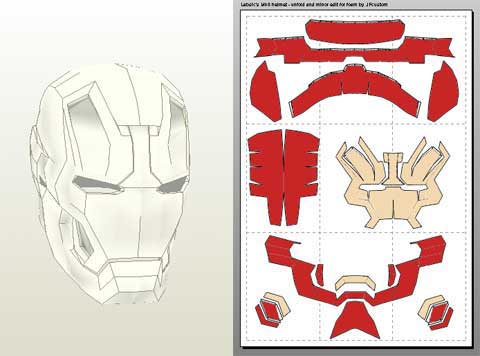

Also Labsic's Mk8 helmet - foam unfold JFcustom.pdo

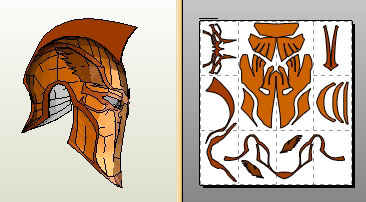

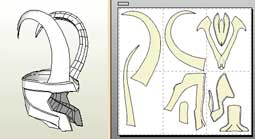

Loki Helmet by KaiserLee - foam unfold JFcustom.pdo

Tip : at the horn gluing stage we have three loooong pieces to snap together. To be sure to obtain a well curved horn, you may want to face them up first and glue them point by point, this way :

This process should be applied to glue correctly any long side in general.

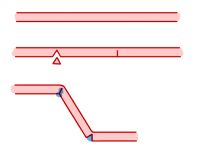

You may also applie these process if needed : thin the foam on the gluing area, or plainly cut up your pieces of foam without caring about the dot-lined overlap you'll see on the pep files. Illustration :

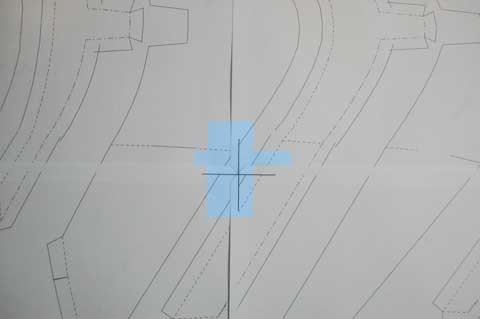

The dotted lines along the borders of the paper templates are here to delimitate

- the real outter side of the suit (in grey)

from

- the strip that will recieve glue and will be overlapped (in blue) by another piece of foam.

If you're using your 12mm foam, by thinning the blue area you can act like if you were working with some 6mm foam, or you can also completely remove this blue edge depending of the method you plan to assemble your foam pieces.

I've been asked if I had used some 2, 3 or 5 mm when building Sharkhead's helmet, in fact it was some 7mm foam. The illusion was due to the fact that I used several ways to snap the pieces of foam together, depending of the rendering I expected at the surface. Low, medium, heigh, and progressive step :

Gluing pieces side to side will probably be less strong, but will it be not strong enough ? I can't say. No dammage here so far.

One simple thing also is you don't have to mix the dotted lines that represent a mountain or a valley, with the dotted lines that delimit a gluing area. But it might not be much harder on the templates than on the picture below :

In case of doubt, always refer to the 3D view of Pepakura viewer...

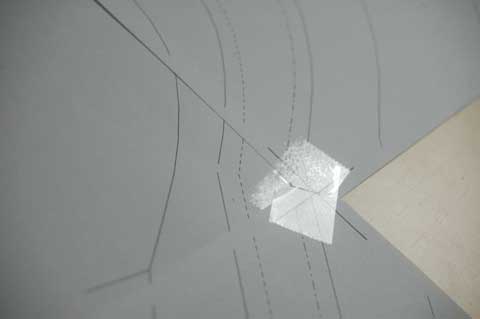

I've also been asked to show the way I translate the dotlines from the paper patterns to the inner side of the foam pieces.

We assume a suit is always symetric, we have only one paper template (let's say it's the right side one) and we are at the point we've already managed to cut up two mirrored foam pieces from it.

So, here I lay down the right paper template over the inner side of the left foam piece. With a pen I punch a hole at every strategical point, in order to locate the placement of the lines.

When removing the paper, I see the dots my pen made.

From them I can draw the same lines onto my foam.

Now, I flip my paper mask and lay it over the other foam part, the right side one.

The printed side of the paper is hidden, I can't see my dot lines anymore but I don't care : I still have my previous dot holes. I use my pen once more to mark the placement of these holes.

Here I am. Now I can bin my paper pattern...

...and trace the lines on this second and last foam piece.

My printed lines are accurately transposed, I can cut my hills and valleys...

To fill the remaining gaps, and unexpected valleys, and overall every 'factory-dammages', I don't think any sandable product can go well. Because foam is flexible, and something you can sand is not. As a result your join will keep on breaking at every bending. I've successfully tryed a simple and common alternative : the silicone bathroom mastic-glue-gun.

It sticks, it fills, it's slick and smooth, and it can be shaped. The only thing is you must paint it or primer it with any spray you want before it's dry, or nothing will further hold on to this stuff.

_______

If it's your first step into foam, I suggest you to try your hand on this realy quick and and quite simple Cap' helmet :

Howto :

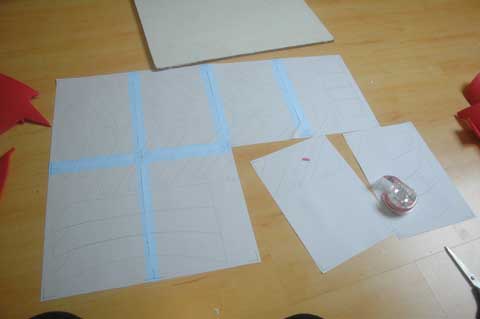

After having ticked "print alignment marks for multiple pages" in "setting / print setting", you can print your pages. Then, cut away the top and left margins of each of them, and then tape all of them together to obtain a laaarge single page.

Then, cut out your paper pieces just like they are.

If these pieces are too large for your foam hight or width, you'll have to choose between cutting your piece of paper in smaller parts to match your foam sheets size, of seaming multiple foam sheets to obtain a single and large enough foam sheet to match your paper piece size.

Step by step :

Be sure to set A4 or Letter properly, or you'll run the risk to print outside the paper.

You should tape the sheets before cutting the patterns :

1. print your sheets

2. tape your sheets

2.1- match the alignment marks

2.2- tape the corners

2.3- tape the whole meeting sides

... and only then you can cut up your masks. This way you can instantly notice if something's wrong before cuting and before taping, and It prevents both hazardous taping and multiple pieces parts spreading.

3. cut your paper masks

4. cut your foam from the masks

(OR gather 3 and 4 by laying your paper upon your foam to cut both at the same time if you can, you'll save time)

5. you get less and bigger foam parts, you save gluing time, and less junctions means nicer curves an inproved "anti-aliasing".

Now, tips.

Classical cardboard peping is fantastic. Cut all of the pieces, glue them as shown on pepviewer, and from Gabon to Peru you'll get exactly the same shaped armor part.

Foam peping doesn't goes exactly the same, since you use an elastic and springy matérial you can actualy not fold so easily.

However it can be bent and stretched as you like, and it has a practical thickness !

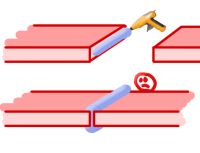

Sharp cutting and clean gluing will make the difference between Iron Man and Jabba the Hutt. So here are some simple tips I used (glue is blue) :

Cut all your foam parts first with no particular angle, some quite right angles would go well, and then, only while assembling, you can adjust inclination edge after edge.

The idea :

The practice :

The result (don't ask, yes it's another piece) :

It's simple as possible : each time the surface of the armor makes an angular outward inflection (not a simple curve, but an real palpable angle), you must make the angled cuts.

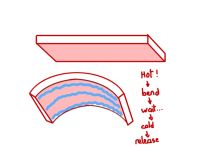

Shaping mountains and valleys :

You'll often have to give a shape to a single piece of foam in order to decrease the amount of seams. This will help a lot :

I've been asked many times for a detailed howto, so here are the steps to follow :

To make a valley, the only trick is not to cut your foam from side to side. Your blade should never cross the outer side of the foam piece.

1- draw your valley with any pen on the inner side of your foam piece,

2- cut along this line by an angle of 90° in a single pass, without perforate the foam,

3- fold your valley to its desired angle,

4- apply glue inside the notch,

5- wait...

6- release, it's done.

Making a mountain is nearly the same, but you have to make a double cut, in order to remove a long toblerone-shaped piece of foam.

1- draw your mountain on the inner side,

2- cut on either side of this line by an angle of 45°, more or less depending of the desired salient of your mountain, each cut in a single pass, without perforate the foam,

3- remove the toblerone, and apply glue inside the notch,

4- fold your mountain to its desired angle,

5- wait...

6- release, it's done.

If you flunk, don't panic : re-heat the cold glue so you can inflect the angle.

The most important thing is to keep your blade damn-sharped !

And before you ruin your WM, I suggest you could pactice with waste foam pieces... until you're self-confident.

forcing a curve :

And here are some close'ups of the way I use the overlaps to build quite cleanly most of a suit's parts. Here, a back part.

No this picture hasn't been photoshopized, and yes I use a common glue gun :

strengthening rotating joins (glue is used as standalone) :

Many of you asked me the way I get net junctions and how I could glue pieces together without any glue overflow. In fact, there IS always glue overflow... but not outside the suit.

bad ->

good ->

Easy.

A quick example of the cheapest pivoting juncture ever :

from a plastic bottle

spare all parts

cut the bottleneck this way

glue the ring inside the border of a round hole in the upper foam piece

glue the bottleneck trough a second hole in the lower foam piece

and reassemble the same it primarily was.

Screw the plug back, you're done.

Depending on the thickness of the foam, once screwed it may jam.

In this case the trick is to cut out few millimeters from the bottom of the cap :

That will release the tightening.

And if the plug stands out too much for the smooth design you expected, cut out a ring from the top of the neck too.

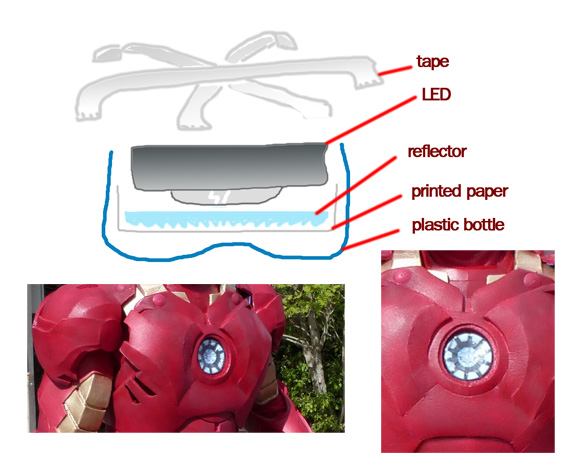

my cheapest operational ARK reactor for moneyless

- you need -

An Evian bottle bottom, 2 inchs height :

One of this kind of pics, of your choice, printed on the thiner paper you can find, cut along the dotted, and then oiled for a better transparency :

A 80mm white round reflector, as you can find at the front of caravans or trailers (keep only the transparent part, of course, but better is to specify it however) :

A led(s) push-spot

and a roll of tape

- HOW TO -

Fill your bottle's bottom with

1. pic of the ARK, printed side turned down,

2. reflector, rugged side down, slicky side up in front of the leds,

3. led spot, lights turned to the reflector

4. cross tape your bottom's bottle to keep all inside in place.

5. Insert the thing in your chest, it fits perfectly, and holds alone.

Push, it works.

Price : 2$

In a similar spirit, have a look at Freaklord's Cheap Iron Man Repusors, that are well worth to be referenced and earn to be quoted.

Joining articulated (and also some sealed) parts :

I used to work as graphist in a publicity agency, and we had always somewhere in the office a couple of useless and sun-faded color charts.

And ?

And I kept thinking that the potential of these pretty little plastic juncture clips were heavyly underexploited.

So I ordered a pack of 100 pieces, as it almost doesn't costs anything.

You can find some here or here or here or here... of various shape, color, diameter and thickness.

And I promise you some discret and incredibly easy attaching for mobile parts (knees elbow toes...) as well as sealed parts such top chest, flaps, handplates, spin and so on... depending of the pressure when cliping.

Those discrete flat-headed rivets on my kneese are very handy and efficient. But they can not be unfasten (except by using barbarian way). Once cliped, you only have to chose between : you leave it alone, or you clip it harder. The axis is toothed so they act just like you car's hand brake.

Coke caps are easyer to find, and can be unscrewed. And to quote Jonny, "the botte neck is quite wide so it's less likely to rip the foam".

Might be a good alternative to the clips I use (and maybe available in the US ?)

_______

How to sharpen a blade.

You're allowed to disbelieve : I use the same blade since april. I'm a tightwad... :lol

If foam by itself is able to blunt a blade, then something as soft as foam may also sharpen it. The main trick is NOT to take an aggressive nor fierce material. No whetstone, no grindstone, no polishing Dremel tip, not event the thinest sanding paper... Something just like Death, in "Reaper man" from Terry Pratchett, is sharpening his scytheblade using wind and moonlight until it can even cut a conversation.

Sharpener multipurpose SANSON cristal - Precise and fine sharpening

A single and light pass, your blade slides between two tungsten slabs, it takes half a second, and then it cuts better than when it was new.

It's not a joke.

It really cuts better than when it was new.

5 years guarantied.

It makes my life a thousand times easier. I don't know how I could do without for so long...

_________________________________

ArmorAsylum video(s) :

Well it's me, in fact... on ArmorAsylum channel

Cullen Cosplay video(s) :

He's one of us. If you don't recognize his face, you'll recognize his work ^^

Aside the flowers he sends me, he shows and explains for real how to use foam along with the templates available on this thread. Trust it's much more efficient than reading 50 pages. Keep tunned on Cullen Cosplay channel...

After a basic but effective five-days-built Iron Man Mark IV, I wanted to improve and share my speed-building technics to allow everyone having kids and a full-time job to be still able to build a full foam suit in far less than a month. And it begins with releasing some suitable *.pdo files.

By suitable I don't mean at all that the other guys who unfold for foam should better drop their work right through the gogs. Not at all. By suitable I mean that the templates below can only be used under certain restriction of material :

at first you must use some foam mats, or foam roll, or whatever else, much larger than a common paper sheet. Then, you may use some cheap foam, because these templates generate a impressive amount of waste. And at last, the more your foam is flexible, the more easy will be your build. This point depends mainly of the thickness of this foam. I would recommend somewhere between 5 and 10mm. I use 7mm.

The way I unfold allows each curve and bulge-shaped effect to be obtained without the need of a heat gun. It has occurred that these templates work fairly well with corrugated cardboard, and also, through proper tweaking, for aluminium panels.

But if you plan to use some sheets of foam of one square foot, or one inch thick, or almost unbendable, you won't be able to use these templates. About flexibility, here's a quick illustration of what you'll often have to do with your foam (yea I know, it's paper on the photos, but it's only an illustration) :

This thread aims to gather the models I've unfolded with both "foam" and "speed-build" in mind, as well as the tips that come along with the files. You may notice that some esthetical details are often missing, details like grids, holes, screws, notches, indentations... They have been removed from the templates to build faster, and are called to be added on your own once the armor part is built. Every missing detail can always be implemented afterward. The final shape remains unchanged, you won’t have any ‘more angular’ nor ‘more inflated-like’ body parts than with other files.

At the end we obtain some pepakura files with less and larger pieces, foam flaps for stronger and discrete overlap gluing, and in one word a better compatibility with foam shapeability.

Well at least I assume it is...

__________________________________________________

The files below are, and will remain, unlocked and shared freely for all to download and use, since they are used in the evident respect of legality. Do not go thinking so far that I'm plenty of buckets full of free time to work on these files, because it's not the truth at all. And in order to prevent my wife from strangling me, I promised to add this link.

__________________________________________________

For Iron Man mark 4 and 6 I robbed Robo3687's files, I stole the mark VII in DarkSide501st's pockets, and Dancin_fool has modeled the mark III. A big thank to you, without your work all of us would still keep saving the world in underpants.

If it happens you find here a(n other) file that is not fully credited, please contact me.

All male suits are default scaled for a 6' guy.

Here we are :

robo3687's Iron Man Mark 4/6 - unfold for foam by JFcustom.rar

I've colorized here where to connect the parts together :

And here, how I connected collar plates to the top of the back/chest :

anyway, it's the way I did... The result is a one-piece torso that you put on just like a T-shirt.

Iron Man mark7 by Karol Siemieniago - minor edit and foam unfold JFcustom.rar

Incredibly both movie-looking and simple to build.

DarkSide501st's Iron Man Mark VII - v1.0 - unfold for foam by JFcustom.

I have to reedit some files from the beginning for this suit to be doubt-proof and fully workable. I'll should have join a readme file for this one, because I think that some tips need to be explain before you drive straight against the wall...

Note that gloves, brace, collar, collar plate, and neck are missing from MkVII package. You can pick them from Mk2, 3 or 4.

EyeofSauron's Iron Man Extremis - unfold for foam by JFcustom.rar

Iron Man Extremis v2 - foam unfold JFcustom.rar

classic iron man provided by EyeOfSauron - foam unfold JFcustom.rar

Marvel, Zabanna, and BenStreeper's Iron Man Ultimate V2 - unfold for foam by JFcustom.

Link to the rar file in the post by CSM-101 (me) time stamped 02-18-2013, 02:25 AM

Tribes Ascend - heavy armor - JFcustom foam files.rar

Robo3687's War Machine - unfold for foam by JFcustom.

All included but heavy weapons. Helmet design by Stark1138.

Iron Patriot by Jackieisrockin - foam unfold JFcustom.rar

Briareos by C2/Lord Harnor/Dung0Beetle/JFcustom - foam unfold JFcustom.rar

Guyver the Bioboosted Armor - FOAM edit and unfold JFcustom.rar

At last. Full from head to toes. The 6 tubes on the sides of the chest, as well as the spheres on the helmet are left to be freehanded.

Predator - foam edit & unfold JFcustom.rar

Cyberman - foam unfold JFcustom.rar

c3po.rar

BSD's Rex PhaseII - foam ufold JFcustom.rar

Dancin_Fool's Iron Man MkII/MkIII - unfold for foam by JFcustom.

To go at simplest, every detail missing from the original model (grids, holes, screws, notches, indentations...) will have to be added manualy afterward by directly sculpting them into the foam. Please refer to Dancin_Fool's files or included ref pics.

Vanquish ARS provided by Tumbucu1 - unfold for foam by JFcustom.

A huge painting work to make this one look good, but I think it can worth the time spent. The files in the rar may be updated without warning during the coming days.

Thor - unfold for foam by JFcustom.

Helmet model by Dung0beetle, I don't know who created the other parts...

Pepper Potts Rescue Armor - foam edit JFcustom.rar

Credits :

Back and torso modeled by Eirth @405th

Arms from a Halo mkVI modeled by Robogenesis @405th

Helmet is IM comic version from EyeOfSauron

All other parts provided by EyeOfSauron's Extremis suit.

All of these post-edited to fit a woman's body.

An overview pic here.

The suit is scaled for a 1m70 heigh girl. (ie 5'7")

Nightingale female suit - The Elder Scrolls V - Skyrim - foam unfold JFcustom.rar

Skyrim - Female Daedric armor - foam unfold.rar

Snow White Armor - model and foam unfold JFcustom.rar

Iron Man MK1 - cave suit.rar

S-CRY-ed Kasuma's arm - foam unfold JFcustom.pdo

Rhinoc's predator biohelmet - foam unfold JFcustom.pdo

Darkside501st's iron patriot helmet - foam unfold JFcustom.pdo

TDK cowl - foam unfold JFcustom.pdo

Batman Arkham cowl - foam unfold JFcustom.pdo

Arkham Origins Batman cowl - foam unfold JFcustom.pdo

DCU - Hawkman cowl - foam unfold JFcustom.pdo

DCU - Fate helmet - foam unfold JFcustom.pdo

DCU - Hawkgirl cowl - foam unfold JFcustom.pdo

JFcustom's Arkham-Deathstroke.pdo

Injustice - Deathstroke Helmet - JFC foam.pdo

Guardians of the Galaxy - StarLord helmet.pdo - model and foam unfold JFcustom.pdo

Titanfall pilot helmet 1 - JFC foam.pdo

freedom gundam helmet - foam unfold JFcustom.pdo

Landmate helmet - foam unfold JFcustom.pdo

classic iron man helmet by EyeofSauron - foam unfold JFcustom.pdo

omarbou1-ironmanmark7v2helmet-jfcfoam.pdo

Iron Patriot by Jackieisrockin - 13 - helmet - foam unfold JFcustom.pdo

Multi-hero cowl - Blue Beetle pattern - model and foam unfold JFcustom.pdo

Wolverine cowl - foam unfold JFcustom

Rinzler helmet - foam unfold JFcustom.pdo

Obito war mask.pdo

Embo hat-shield.pdo

About the thickness, you'll just have to add two or three circles of foam between the two layers to make it keep its shape, just like that :

c3po-head.pdo

Dark Vader helmet - foam unfold JFcustom.pdo

Dredd 2012 helmet by Dung0Beetle and Blaxmyth - Foam edit and unfold JFcustom.pdo

Dwarf helmet.pdo

Jango FETT helmet - foam unfold JFcustom.rar

Rocketeer helmet - edit and foam unfold JFcustom.pdo

Dr.Fate helmet - foam unfold JFcustom.pdo

Guyver 3 helmet - foam unfold JFcustom.pdo

Yoda's head.rar

Dung0beetle's Spaceballs Dark Helmet - foam unfold JFcustom.pdo

and the little prop that comes along :

Spaceballs - Dark Helmet's coffee cup.rar

BTTF Mr. Fusion - JFC foam.pdo

Mind the scale before printing.

Daft Punk - Cama900's GuyMan Helmet - Foam edit and unfold JFcustom.pdo

Daft Punk - Dung0Beetle's Thomas Helmet - Foam edit and unfold JFcustom.pdo

sg - shoulder cowl base.pdo

sg - woof.pdo

sg - chirp.pdo

foam-pumpkin.pdo

christmastree - foam unfold JFcustom.pdo

Few accessories that come along with the Predator suit :

weapons :

predator-battledisc.pdo

spear.pdo

and trophys :

human vertebra.pdo

Build several ones with a slightly changing scale to get a realistic full spine.

(almost) human skull.pdo

Alien head - provided by Movieman - foam unfold JFcustom

And to both solve the issue of the lower eyes that happen to bulge way out, as described here, and improve the details of the ears area, here's an enhanced unfolding version of Sharkhead's Iron Man Helmet :

Sharkhead7854-ironman-helmet-foam-unfold-by-JFcustom.pdo

Also Labsic's Mk8 helmet - foam unfold JFcustom.pdo

Loki Helmet by KaiserLee - foam unfold JFcustom.pdo

Tip : at the horn gluing stage we have three loooong pieces to snap together. To be sure to obtain a well curved horn, you may want to face them up first and glue them point by point, this way :

This process should be applied to glue correctly any long side in general.

You may also applie these process if needed : thin the foam on the gluing area, or plainly cut up your pieces of foam without caring about the dot-lined overlap you'll see on the pep files. Illustration :

The dotted lines along the borders of the paper templates are here to delimitate

- the real outter side of the suit (in grey)

from

- the strip that will recieve glue and will be overlapped (in blue) by another piece of foam.

If you're using your 12mm foam, by thinning the blue area you can act like if you were working with some 6mm foam, or you can also completely remove this blue edge depending of the method you plan to assemble your foam pieces.

I've been asked if I had used some 2, 3 or 5 mm when building Sharkhead's helmet, in fact it was some 7mm foam. The illusion was due to the fact that I used several ways to snap the pieces of foam together, depending of the rendering I expected at the surface. Low, medium, heigh, and progressive step :

Gluing pieces side to side will probably be less strong, but will it be not strong enough ? I can't say. No dammage here so far.

One simple thing also is you don't have to mix the dotted lines that represent a mountain or a valley, with the dotted lines that delimit a gluing area. But it might not be much harder on the templates than on the picture below :

In case of doubt, always refer to the 3D view of Pepakura viewer...

I've also been asked to show the way I translate the dotlines from the paper patterns to the inner side of the foam pieces.

We assume a suit is always symetric, we have only one paper template (let's say it's the right side one) and we are at the point we've already managed to cut up two mirrored foam pieces from it.

So, here I lay down the right paper template over the inner side of the left foam piece. With a pen I punch a hole at every strategical point, in order to locate the placement of the lines.

When removing the paper, I see the dots my pen made.

From them I can draw the same lines onto my foam.

Now, I flip my paper mask and lay it over the other foam part, the right side one.

The printed side of the paper is hidden, I can't see my dot lines anymore but I don't care : I still have my previous dot holes. I use my pen once more to mark the placement of these holes.

Here I am. Now I can bin my paper pattern...

...and trace the lines on this second and last foam piece.

My printed lines are accurately transposed, I can cut my hills and valleys...

To fill the remaining gaps, and unexpected valleys, and overall every 'factory-dammages', I don't think any sandable product can go well. Because foam is flexible, and something you can sand is not. As a result your join will keep on breaking at every bending. I've successfully tryed a simple and common alternative : the silicone bathroom mastic-glue-gun.

It sticks, it fills, it's slick and smooth, and it can be shaped. The only thing is you must paint it or primer it with any spray you want before it's dry, or nothing will further hold on to this stuff.

_______

If it's your first step into foam, I suggest you to try your hand on this realy quick and and quite simple Cap' helmet :

Howto :

After having ticked "print alignment marks for multiple pages" in "setting / print setting", you can print your pages. Then, cut away the top and left margins of each of them, and then tape all of them together to obtain a laaarge single page.

Then, cut out your paper pieces just like they are.

If these pieces are too large for your foam hight or width, you'll have to choose between cutting your piece of paper in smaller parts to match your foam sheets size, of seaming multiple foam sheets to obtain a single and large enough foam sheet to match your paper piece size.

Step by step :

Be sure to set A4 or Letter properly, or you'll run the risk to print outside the paper.

You should tape the sheets before cutting the patterns :

1. print your sheets

2. tape your sheets

2.1- match the alignment marks

2.2- tape the corners

2.3- tape the whole meeting sides

... and only then you can cut up your masks. This way you can instantly notice if something's wrong before cuting and before taping, and It prevents both hazardous taping and multiple pieces parts spreading.

3. cut your paper masks

4. cut your foam from the masks

(OR gather 3 and 4 by laying your paper upon your foam to cut both at the same time if you can, you'll save time)

5. you get less and bigger foam parts, you save gluing time, and less junctions means nicer curves an inproved "anti-aliasing".

Now, tips.

Classical cardboard peping is fantastic. Cut all of the pieces, glue them as shown on pepviewer, and from Gabon to Peru you'll get exactly the same shaped armor part.

Foam peping doesn't goes exactly the same, since you use an elastic and springy matérial you can actualy not fold so easily.

However it can be bent and stretched as you like, and it has a practical thickness !

Sharp cutting and clean gluing will make the difference between Iron Man and Jabba the Hutt. So here are some simple tips I used (glue is blue) :

Cut all your foam parts first with no particular angle, some quite right angles would go well, and then, only while assembling, you can adjust inclination edge after edge.

The idea :

The practice :

The result (don't ask, yes it's another piece) :

It's simple as possible : each time the surface of the armor makes an angular outward inflection (not a simple curve, but an real palpable angle), you must make the angled cuts.

Shaping mountains and valleys :

You'll often have to give a shape to a single piece of foam in order to decrease the amount of seams. This will help a lot :

I've been asked many times for a detailed howto, so here are the steps to follow :

To make a valley, the only trick is not to cut your foam from side to side. Your blade should never cross the outer side of the foam piece.

1- draw your valley with any pen on the inner side of your foam piece,

2- cut along this line by an angle of 90° in a single pass, without perforate the foam,

3- fold your valley to its desired angle,

4- apply glue inside the notch,

5- wait...

6- release, it's done.

Making a mountain is nearly the same, but you have to make a double cut, in order to remove a long toblerone-shaped piece of foam.

1- draw your mountain on the inner side,

2- cut on either side of this line by an angle of 45°, more or less depending of the desired salient of your mountain, each cut in a single pass, without perforate the foam,

3- remove the toblerone, and apply glue inside the notch,

4- fold your mountain to its desired angle,

5- wait...

6- release, it's done.

If you flunk, don't panic : re-heat the cold glue so you can inflect the angle.

The most important thing is to keep your blade damn-sharped !

And before you ruin your WM, I suggest you could pactice with waste foam pieces... until you're self-confident.

forcing a curve :

And here are some close'ups of the way I use the overlaps to build quite cleanly most of a suit's parts. Here, a back part.

No this picture hasn't been photoshopized, and yes I use a common glue gun :

strengthening rotating joins (glue is used as standalone) :

Many of you asked me the way I get net junctions and how I could glue pieces together without any glue overflow. In fact, there IS always glue overflow... but not outside the suit.

bad ->

good ->

Easy.

A quick example of the cheapest pivoting juncture ever :

from a plastic bottle

spare all parts

cut the bottleneck this way

glue the ring inside the border of a round hole in the upper foam piece

glue the bottleneck trough a second hole in the lower foam piece

and reassemble the same it primarily was.

Screw the plug back, you're done.

Depending on the thickness of the foam, once screwed it may jam.

In this case the trick is to cut out few millimeters from the bottom of the cap :

That will release the tightening.

And if the plug stands out too much for the smooth design you expected, cut out a ring from the top of the neck too.

my cheapest operational ARK reactor for moneyless

- you need -

An Evian bottle bottom, 2 inchs height :

One of this kind of pics, of your choice, printed on the thiner paper you can find, cut along the dotted, and then oiled for a better transparency :

A 80mm white round reflector, as you can find at the front of caravans or trailers (keep only the transparent part, of course, but better is to specify it however) :

A led(s) push-spot

and a roll of tape

- HOW TO -

Fill your bottle's bottom with

1. pic of the ARK, printed side turned down,

2. reflector, rugged side down, slicky side up in front of the leds,

3. led spot, lights turned to the reflector

4. cross tape your bottom's bottle to keep all inside in place.

5. Insert the thing in your chest, it fits perfectly, and holds alone.

Push, it works.

Price : 2$

In a similar spirit, have a look at Freaklord's Cheap Iron Man Repusors, that are well worth to be referenced and earn to be quoted.

Joining articulated (and also some sealed) parts :

I used to work as graphist in a publicity agency, and we had always somewhere in the office a couple of useless and sun-faded color charts.

And ?

And I kept thinking that the potential of these pretty little plastic juncture clips were heavyly underexploited.

So I ordered a pack of 100 pieces, as it almost doesn't costs anything.

You can find some here or here or here or here... of various shape, color, diameter and thickness.

And I promise you some discret and incredibly easy attaching for mobile parts (knees elbow toes...) as well as sealed parts such top chest, flaps, handplates, spin and so on... depending of the pressure when cliping.

Those discrete flat-headed rivets on my kneese are very handy and efficient. But they can not be unfasten (except by using barbarian way). Once cliped, you only have to chose between : you leave it alone, or you clip it harder. The axis is toothed so they act just like you car's hand brake.

Coke caps are easyer to find, and can be unscrewed. And to quote Jonny, "the botte neck is quite wide so it's less likely to rip the foam".

armynavy said:Doll joints works great when putting together the bicep/forearm, and the thigh/shin.

Might be a good alternative to the clips I use (and maybe available in the US ?)

_______

How to sharpen a blade.

You're allowed to disbelieve : I use the same blade since april. I'm a tightwad... :lol

If foam by itself is able to blunt a blade, then something as soft as foam may also sharpen it. The main trick is NOT to take an aggressive nor fierce material. No whetstone, no grindstone, no polishing Dremel tip, not event the thinest sanding paper... Something just like Death, in "Reaper man" from Terry Pratchett, is sharpening his scytheblade using wind and moonlight until it can even cut a conversation.

Sharpener multipurpose SANSON cristal - Precise and fine sharpening

A single and light pass, your blade slides between two tungsten slabs, it takes half a second, and then it cuts better than when it was new.

It's not a joke.

It really cuts better than when it was new.

5 years guarantied.

It makes my life a thousand times easier. I don't know how I could do without for so long...

_________________________________

ArmorAsylum video(s) :

Well it's me, in fact... on ArmorAsylum channel

Cullen Cosplay video(s) :

He's one of us. If you don't recognize his face, you'll recognize his work ^^

Aside the flowers he sends me, he shows and explains for real how to use foam along with the templates available on this thread. Trust it's much more efficient than reading 50 pages. Keep tunned on Cullen Cosplay channel...

Last edited: