Not a huge amount of progress on this, but some I thought I'd share.

Back in October-ish, the first part I made for this project were the gun platform windows. I 3D Printed them from stl's I purchased online. After printing I realized there were quite a few issues with the model, not the least of which being the 'spokes' of the window frame are not straight across from their opposite number and they're too thick.

This is the purchased model shown in Blender. After printing it, I decided I could do better.

I decided to remodel the window myself in Blender with the printed result in the photo below on the left. But after printing it, I still wasn't happy. So I took my 3D model, with the correct dimensions, and exported it out to as a flat template to print on a paper. That template was then cut from Styrene resulting in two scratch built windows using traditional model techniques. The T beams are also correct to what ILM used so I can also say it's "a more accurate replica". I should also mention that the single window on the left took 17 hours to 3D print. I made both windows by hand in under 3 hours.

Both windows are now complete and are waiting to be installed into the Gun Platforms. Which are also finished.

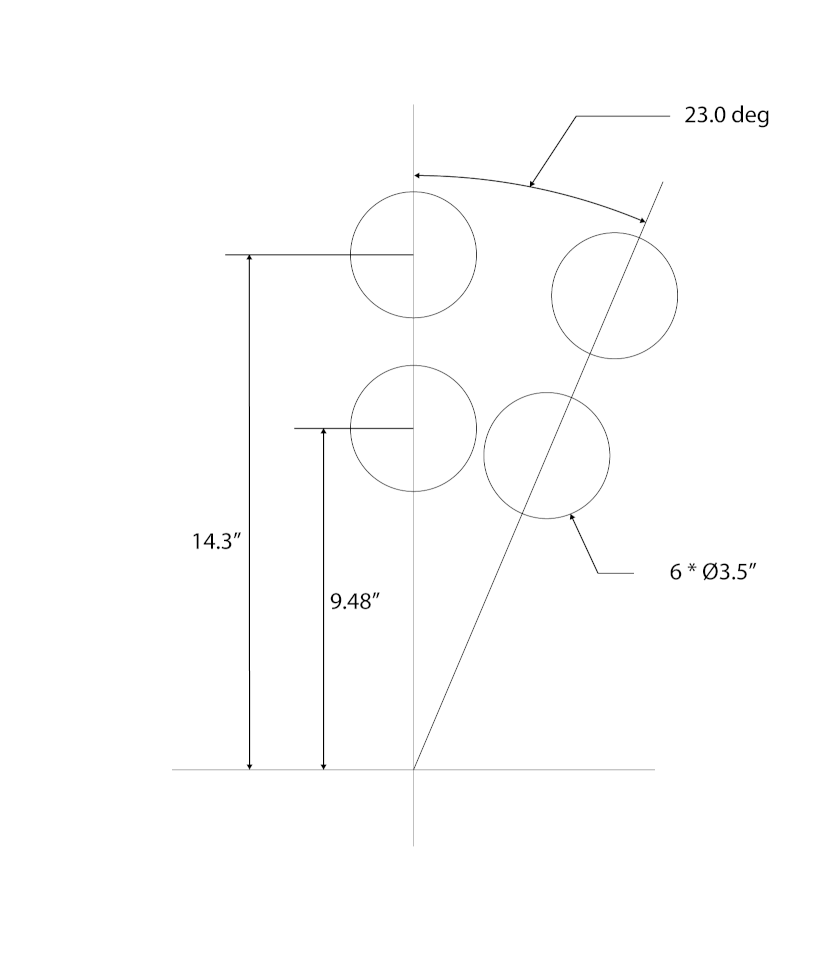

All the 'greeblies' are correct parts from the correct kits. You'll notice that the top most, what I call the, 'gun cap' is 3D Printed. I do have the correct Entex kit part for the top, and I'd considered building the part from scratch and casting it. But instead, I decided to just print two. That Entex part is 3D Modeled to the exact dimensions (inside and out) of the real part, to about 0.01mm, which is the resolution of my printer.

I see a few people using the Fujimi kit's Tank sides for this area, but they should be from the Airfix kit, so that's what I used here. ILM sort of frustrates me because they seemed to like to use 1 part, from 1 kit, in 1 location, and no other parts from that kit are used, where as they could have used a 90% identical piece from a kit they were already using. I had to buy a Sherman Tank, for one part, and I can't find any other location where other parts from that kit are used. Whereas another Sherman kit they used in multiple places has an almost identical piece in it.

I'm trying to walk a fine line between super accurate vs what's practical to build. I could easily have built one and cast the other cap, but I look at 3D Printing as just a branch of casting. If ILM cast a part, I don't feel too bad 3D Printing it if it makes sense to do it that way. Still, I'm trying to keep the 3D Printing of visible components to as close to zero as I can.

That all said, a lot of the internal frame structure is 3D Printed. I know ILM used wood, but I no longer have an appropriate shop for working with wood and as it's hidden, I'm fine with a 3D Printed framework. It just takes a whole lot longer is all. Those ribs would have taken me a couple of hours to build out of spruce, but they took 2 days to 3D print. The lower half of the central hub (in white) took 81 hours to print. The upper half is currently being printed and when complete, will be another 81 hours. I still have the outer waist to print yet.

And finally for this update, scored a Mint in Box Aurora Sealab kit off of eBay the other night. All parts still in their plastic bags and no assembly. So that made me happy. I've sort of given up waiting for the "re-issue" version. I've lost confidence of that ever seeing the light of day.

Anyway, that's the update for this build.