jayjayn

Well-Known Member

This is my first thread and have been following therpf for about two months and started my IM suit right away, im very appreciative to be getting so much info from this forum and now i need some help.

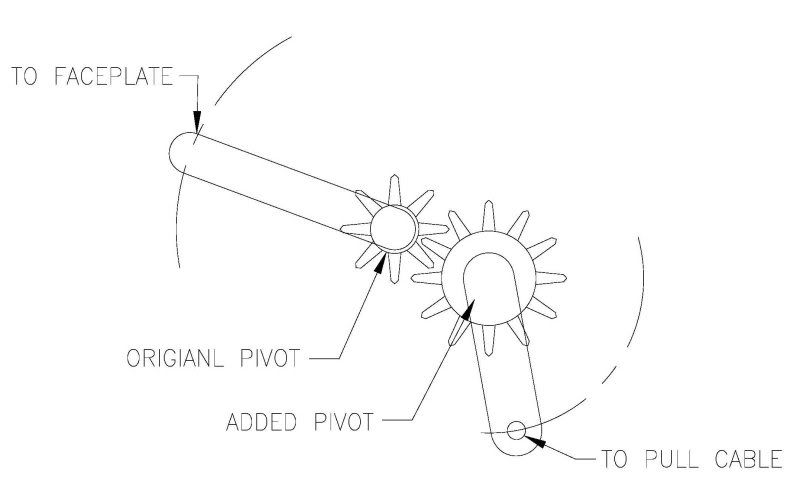

Well i've been having issues trying to get my hinge to work properly due to the amount of throw required to pull brake cables and how much it needs to go back to close the helmet.

I'm using a great detailed helmet from mightyjohn and he made me hinges for the setup here is a video of what im trying to get to work.

IRON MAN HELMET EYES LIGHT UP AND MOTORIZED HINGE TEST - YouTube

and this is mightyjohns hinges at work but only being pulled by hand

Ironman Helmet Hinge demo - YouTube

I got some help from Zabana and he suggested originally using two

HexTronik HX12K Standard Metal Gear Servo 55g / 10kg / .16sec

since he was successful utilizing it on his own hinge setup, but after constantly changing angles of the cables and lengths i realized that the servo's wasn't able to pull enough cable to pull the faceplate open.

I was thinking of either getting a longer servo arm and trying that way, but that would be a issue of trying to get that to fit somewhere inside the iron man suit, another thought was utilizing mini linear actuators but they don't seem fast enough and are twice or even more the amount that normal servo's cost.

I was trying to figure out how to modify my servo's for 360 throw but even with that i find there will be issue on trying to have it rotate back without crimping or even trying to put that sort of setup hidden in the suit.

I'm in need of help on what i should do to get the hinges to open up fully and have the whole setup fit somewhere in my suit, anyone with suggestions?

Well i've been having issues trying to get my hinge to work properly due to the amount of throw required to pull brake cables and how much it needs to go back to close the helmet.

I'm using a great detailed helmet from mightyjohn and he made me hinges for the setup here is a video of what im trying to get to work.

IRON MAN HELMET EYES LIGHT UP AND MOTORIZED HINGE TEST - YouTube

and this is mightyjohns hinges at work but only being pulled by hand

Ironman Helmet Hinge demo - YouTube

I got some help from Zabana and he suggested originally using two

HexTronik HX12K Standard Metal Gear Servo 55g / 10kg / .16sec

since he was successful utilizing it on his own hinge setup, but after constantly changing angles of the cables and lengths i realized that the servo's wasn't able to pull enough cable to pull the faceplate open.

I was thinking of either getting a longer servo arm and trying that way, but that would be a issue of trying to get that to fit somewhere inside the iron man suit, another thought was utilizing mini linear actuators but they don't seem fast enough and are twice or even more the amount that normal servo's cost.

I was trying to figure out how to modify my servo's for 360 throw but even with that i find there will be issue on trying to have it rotate back without crimping or even trying to put that sort of setup hidden in the suit.

I'm in need of help on what i should do to get the hinges to open up fully and have the whole setup fit somewhere in my suit, anyone with suggestions?