Hello guys,

I have a pretty big bunch of photos to show tonight!

and sorry, but as always, i'm going to talk and talk and talk... no way around it if you want to follow my runs, it's just who i am ;-)

Doing a run comes with a whole lot of issues to fix all the time, solutions to find and a lot of sweat and stress. For me, it's a constant worry and hope that everything will end up working and that people will be happy with my work.

This run is no different, there are always problems, difficulties and stress. The knurling and modification of the lathe was definitely up there, but here as well, figuring out how I was going to do that very organic curve at the emiter end was a challenge. I'm not working with a CNC and I want my parts to always be super accurate. So I had to find a way to make it happen while doing everything by hand.

I'm happy to repport that the solutions I came up with worked like a charm, it's a very involved and tiring process but the result is perfect and I'm super happy with the parts!

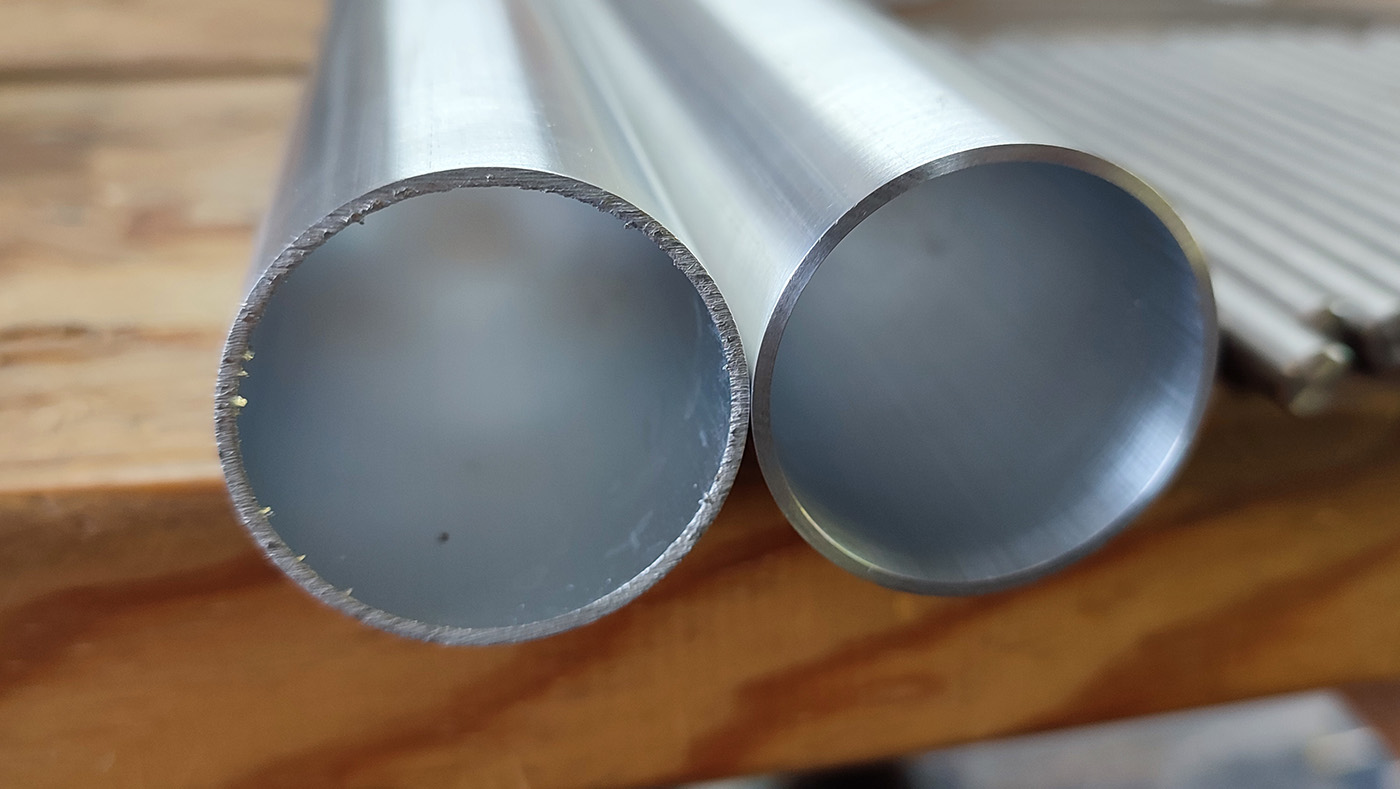

First step on the tubes was to clean the bottom end, it needs to be clean and square to accept the knurled cap nicelly. I actually bought a sanding machine for that step as it's not possible to put such long tubes on my lathe and have them fly around all the time. And, this machine is going to be one of those useless investments i think. I ended up simply milling the ends with the biggest end mill I have and a quick sanding with a fine grit on a flat surface. The result is really clean so all is well

(on the left is straight from the saw, and cleaned up on the right obviously)

Now for the harder part, the front curve.

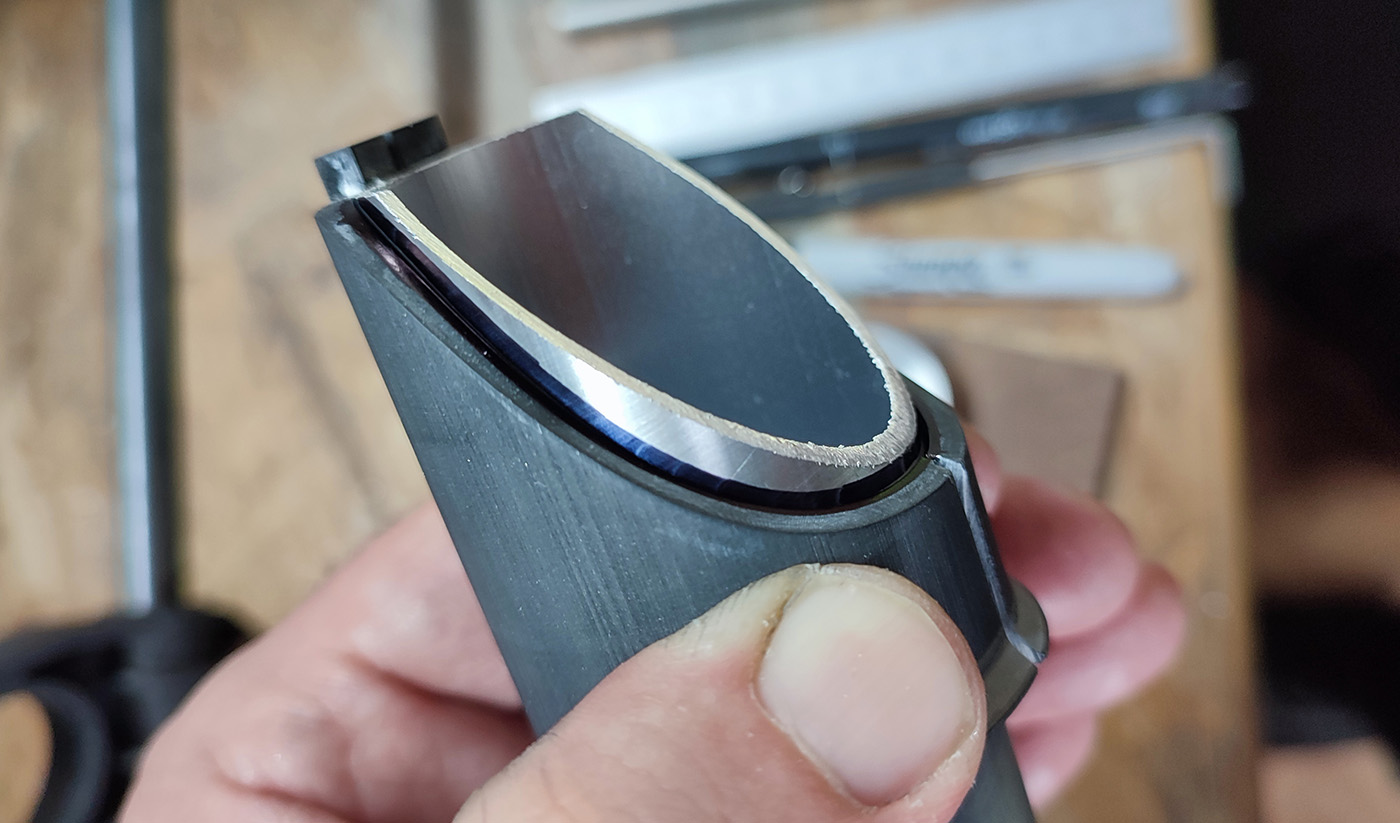

I printed a resin sleeve directly from my matched 3D model so I could trace the actual contour of the shape I want:

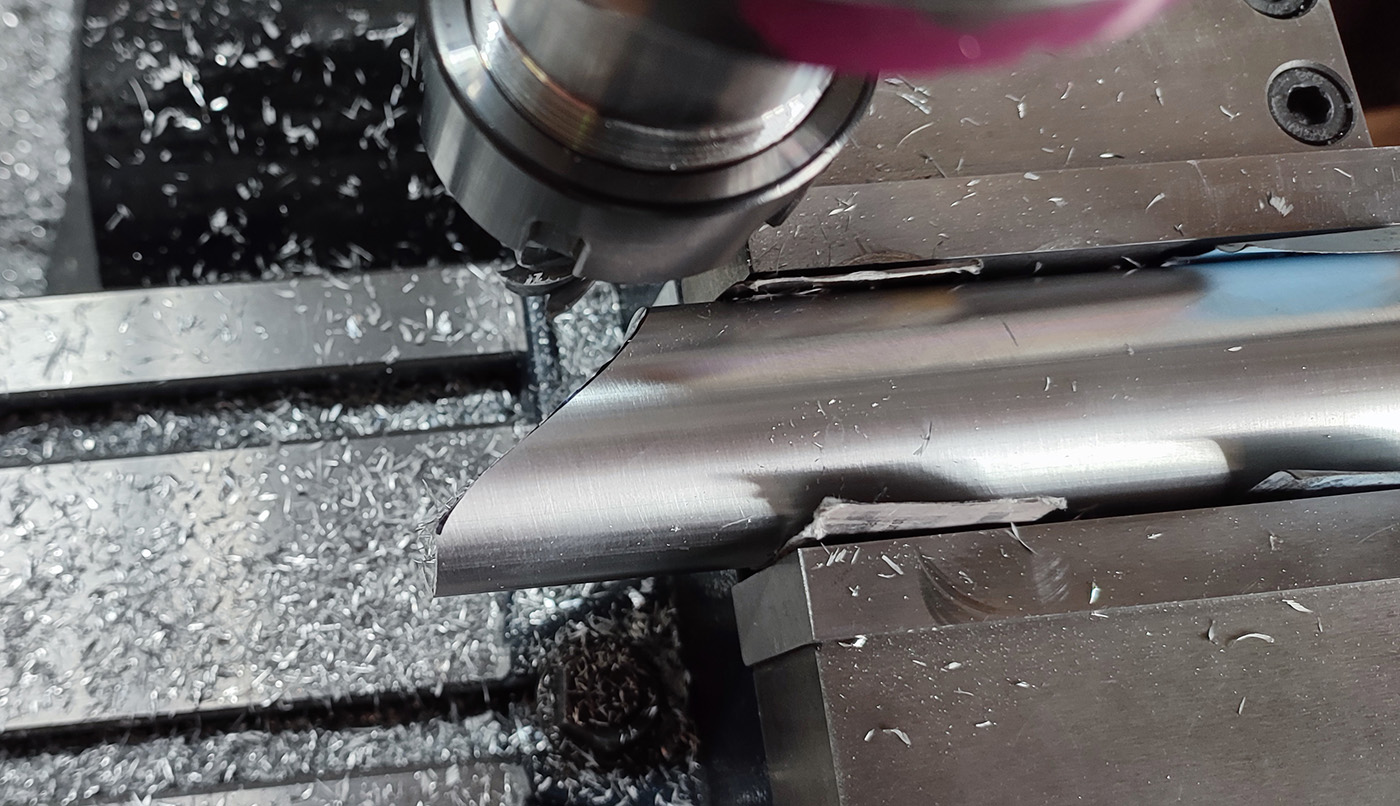

I then need to put the part squared in the mill vice so I can cut both sides at the same time:

then I approximate the shape as close as possible until the black line is almost gone. I have a really bad back and this is the really hard part for me as I need to lean forward most of the time to see what I'm doing. But I'm almost done with the 65 parts and so far so good, just painful, no blocked back.

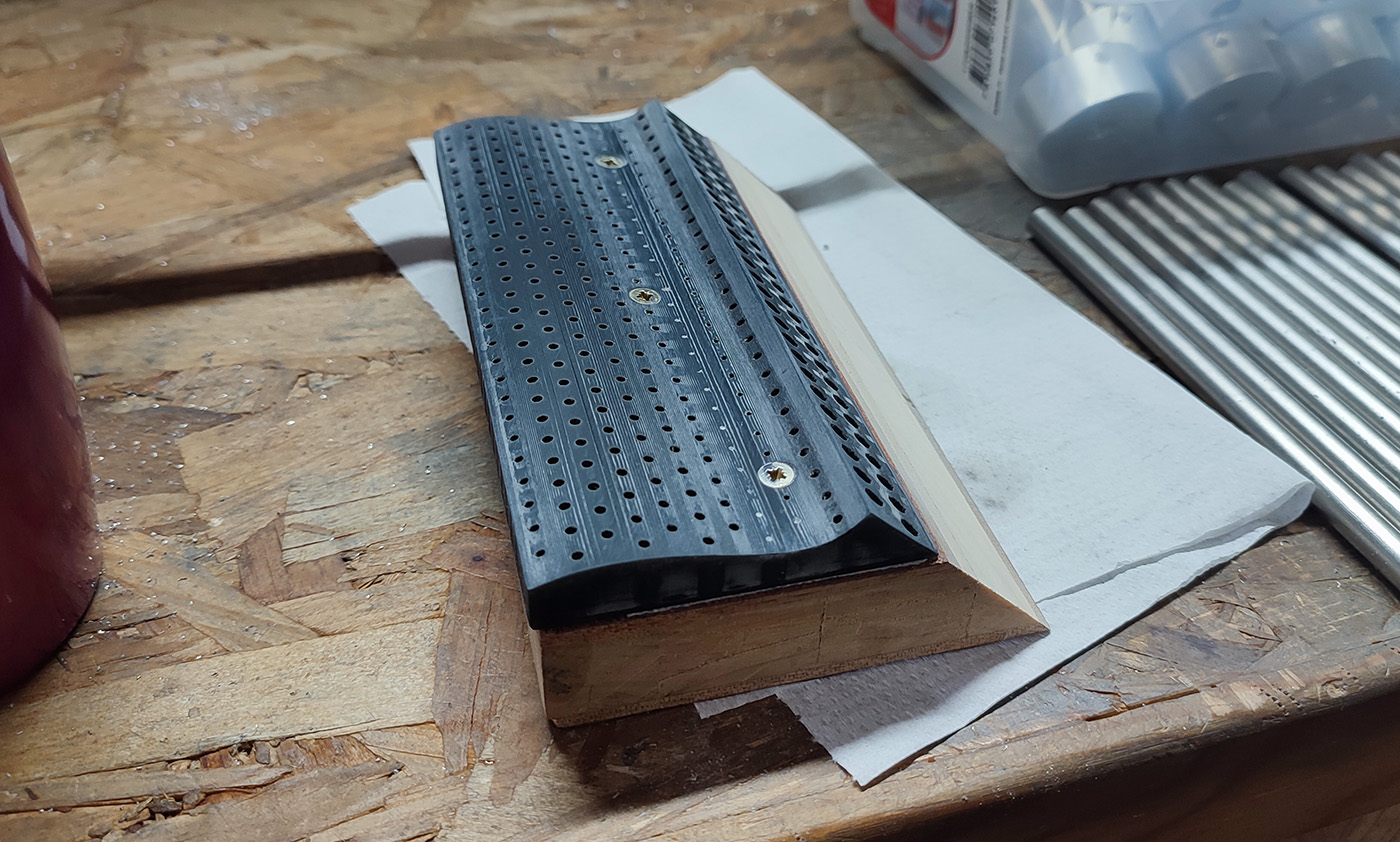

Once this is done, here comes the second cool solution to get a perfect shape. I printed a second jig, taking the exact shape of the emiter straight from my model, printing it flat and attaching adhesive sandpaper to it:

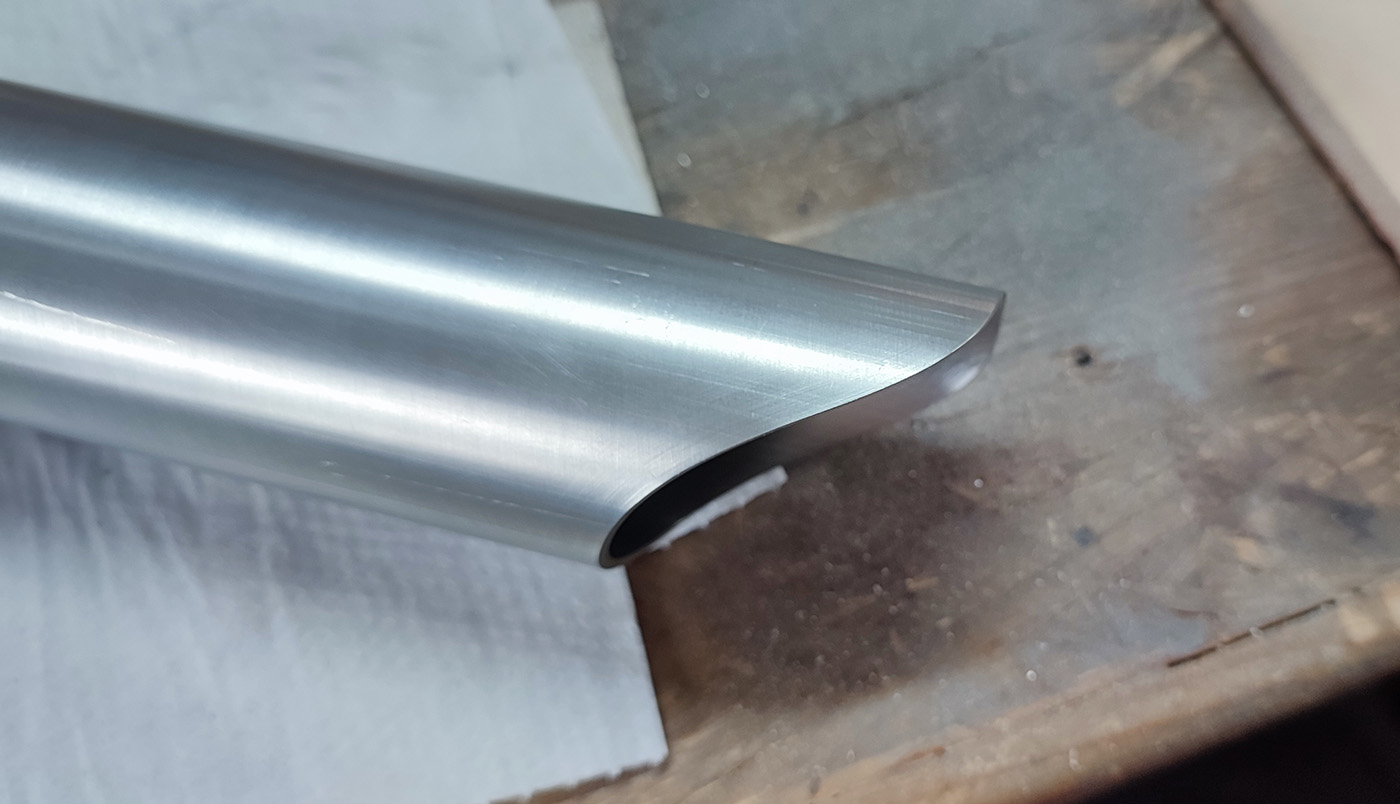

and (9.5 minutes in average of sanding later) voila!

I'm so happy with the result and I hope you guys will like it as well.

This is the exact shape I wanted/needed, the result is clean and perfectly consistent on all tubes. Once again, it's just tiring as 9.5m of sanding per tube adds up very quickly and it's kind of hard to do more than 5 or 6 in a row. But 2 or 3 days from now and that should all be done!

So, still a bit of work, then figuring out the assembled sabers and the motorized sabers especially, but this is shaping up nicelly. I hope you guys will be excited by the update

cheers all!

I have a pretty big bunch of photos to show tonight!

and sorry, but as always, i'm going to talk and talk and talk... no way around it if you want to follow my runs, it's just who i am ;-)

Doing a run comes with a whole lot of issues to fix all the time, solutions to find and a lot of sweat and stress. For me, it's a constant worry and hope that everything will end up working and that people will be happy with my work.

This run is no different, there are always problems, difficulties and stress. The knurling and modification of the lathe was definitely up there, but here as well, figuring out how I was going to do that very organic curve at the emiter end was a challenge. I'm not working with a CNC and I want my parts to always be super accurate. So I had to find a way to make it happen while doing everything by hand.

I'm happy to repport that the solutions I came up with worked like a charm, it's a very involved and tiring process but the result is perfect and I'm super happy with the parts!

First step on the tubes was to clean the bottom end, it needs to be clean and square to accept the knurled cap nicelly. I actually bought a sanding machine for that step as it's not possible to put such long tubes on my lathe and have them fly around all the time. And, this machine is going to be one of those useless investments i think. I ended up simply milling the ends with the biggest end mill I have and a quick sanding with a fine grit on a flat surface. The result is really clean so all is well

(on the left is straight from the saw, and cleaned up on the right obviously)

Now for the harder part, the front curve.

I printed a resin sleeve directly from my matched 3D model so I could trace the actual contour of the shape I want:

I then need to put the part squared in the mill vice so I can cut both sides at the same time:

then I approximate the shape as close as possible until the black line is almost gone. I have a really bad back and this is the really hard part for me as I need to lean forward most of the time to see what I'm doing. But I'm almost done with the 65 parts and so far so good, just painful, no blocked back.

Once this is done, here comes the second cool solution to get a perfect shape. I printed a second jig, taking the exact shape of the emiter straight from my model, printing it flat and attaching adhesive sandpaper to it:

and (9.5 minutes in average of sanding later) voila!

I'm so happy with the result and I hope you guys will like it as well.

This is the exact shape I wanted/needed, the result is clean and perfectly consistent on all tubes. Once again, it's just tiring as 9.5m of sanding per tube adds up very quickly and it's kind of hard to do more than 5 or 6 in a row. But 2 or 3 days from now and that should all be done!

So, still a bit of work, then figuring out the assembled sabers and the motorized sabers especially, but this is shaping up nicelly. I hope you guys will be excited by the update

cheers all!