Too late to the party... sorry, I posted these before hitting "refresh"!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4' (AKA 5 foot) Falcon build

- Thread starter RealDaveWinter

- Start date

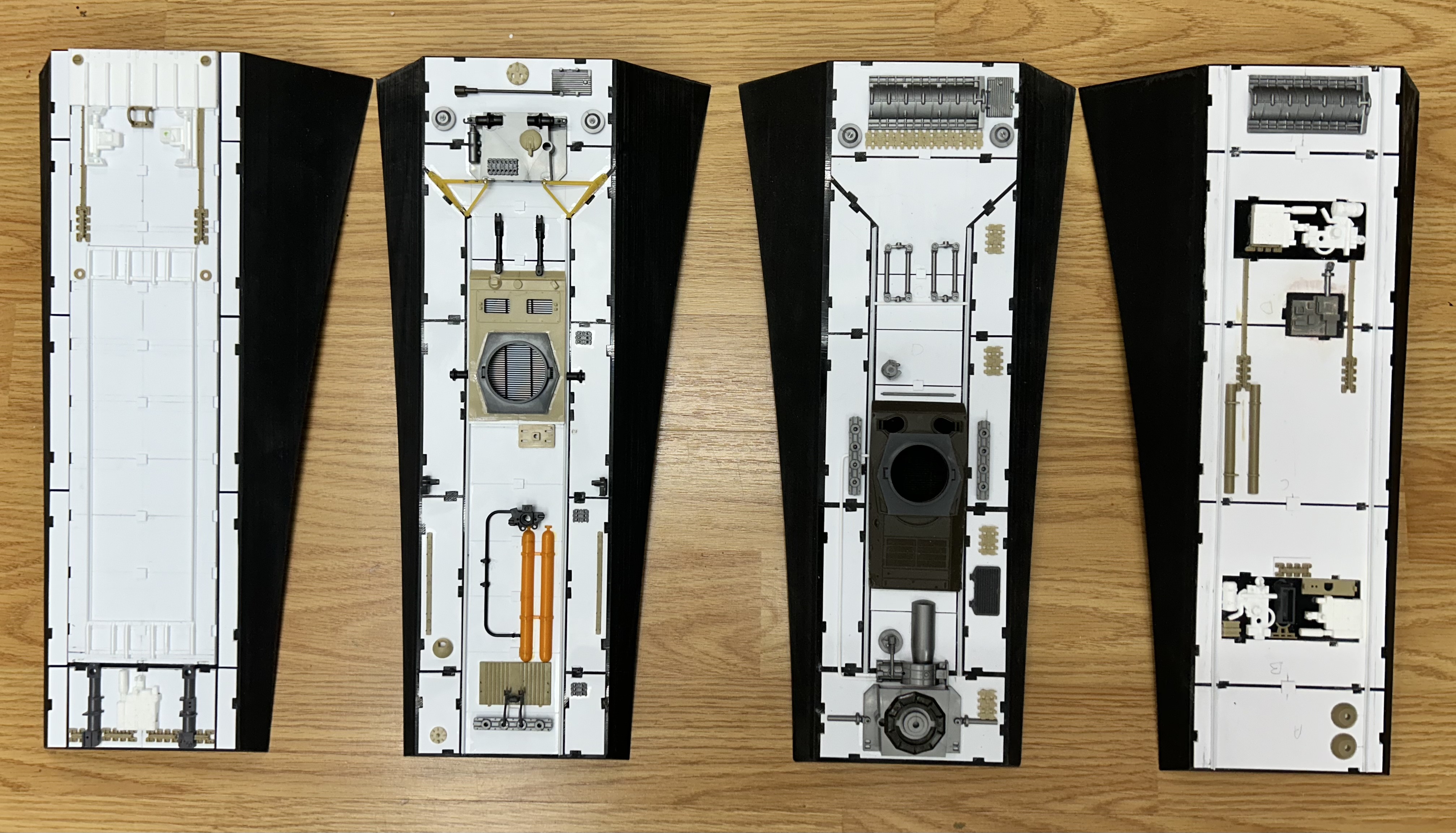

So this is where I am with my build and the walk ways. The top and bottom starboard side are completed. The bottom port is also completed. I'm waiting on a casting from Studio Kitbash of the M60 part 37 to complete the top port. I've tried to use as many real kit parts as possible, but sadly there are a lot more castings than I'd hoped for. Certainly most of the Tamiya Centurion parts are casts from the one kit I have.

These are not 100% perfect. I'm sure things are off by a mm or two here and there, but I've tried to get as close as I can.

[edit] the weird camera angle makes some of these look a bit wonky but the parts are properly aligned.

These are not 100% perfect. I'm sure things are off by a mm or two here and there, but I've tried to get as close as I can.

[edit] the weird camera angle makes some of these look a bit wonky but the parts are properly aligned.

Looking awesome Dave!

Looks great.

Purrrrr-fection. It looks flawless. NICE

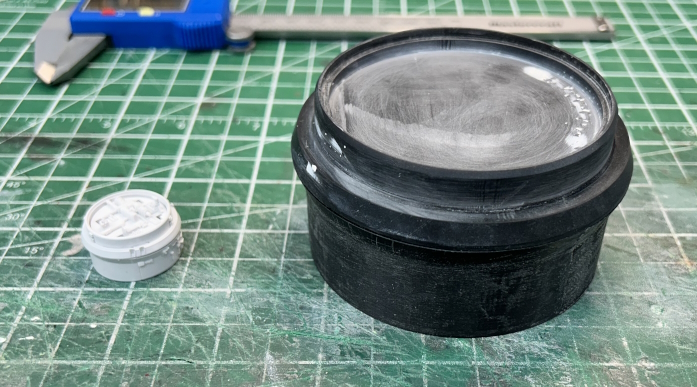

Plugging away with the radar dish portion of things. Yesterday I designed and printed the upper and lower base.

The dimensions are extrapolated primarily from the Bandai kit parts. The upper portion (right) is resin printed, the lower portion is FDM printed and sort of reminds me of an EDF duct. Some light sanding (and some minor filling) and I think it turned out pretty well. I've already dry fitted the greeblies in the upper portion and it looks to be accurate in size.

The dimensions are extrapolated primarily from the Bandai kit parts. The upper portion (right) is resin printed, the lower portion is FDM printed and sort of reminds me of an EDF duct. Some light sanding (and some minor filling) and I think it turned out pretty well. I've already dry fitted the greeblies in the upper portion and it looks to be accurate in size.

These are the STL's for the whole unit.

[edit] I should mention that for FDM printing I use basic PLA, a .15mm layer height, and a .30mm nozzle. This allows me to insure correct dimensions and provides a (reasonably) smooth print.

[edit] I should mention that for FDM printing I use basic PLA, a .15mm layer height, and a .30mm nozzle. This allows me to insure correct dimensions and provides a (reasonably) smooth print.

Attachments

Last edited:

I've assembled the forward half of the internal frame waist band. I'm continually surprised at just how big this is going to be.

I've included a Muggins for scale.

I've included a Muggins for scale.

He's more Muppet than feline.

Dave,a

Thanks for the side by side display of your walk way photos. Great for checking things as I too to strategize completion of needed kit parts. SK’s casting process is excellent and high quality by the way even for the very small stuff.

Cycling back and forth “counting coup” on around 13 engine maintenance pits pieces is also pushing my schedule by giving me more fun than necessary. Making some of these in metal only when good pictures of these small parts can be found.

Thanks for the side by side display of your walk way photos. Great for checking things as I too to strategize completion of needed kit parts. SK’s casting process is excellent and high quality by the way even for the very small stuff.

Cycling back and forth “counting coup” on around 13 engine maintenance pits pieces is also pushing my schedule by giving me more fun than necessary. Making some of these in metal only when good pictures of these small parts can be found.

Looks good. Just be aware that the tolerances in those files are designed around top part resin, bottom part FDM (which is generally less dimensionally accurate), so you might have to ream the centre of the lower portion to make that positioning stud fit.

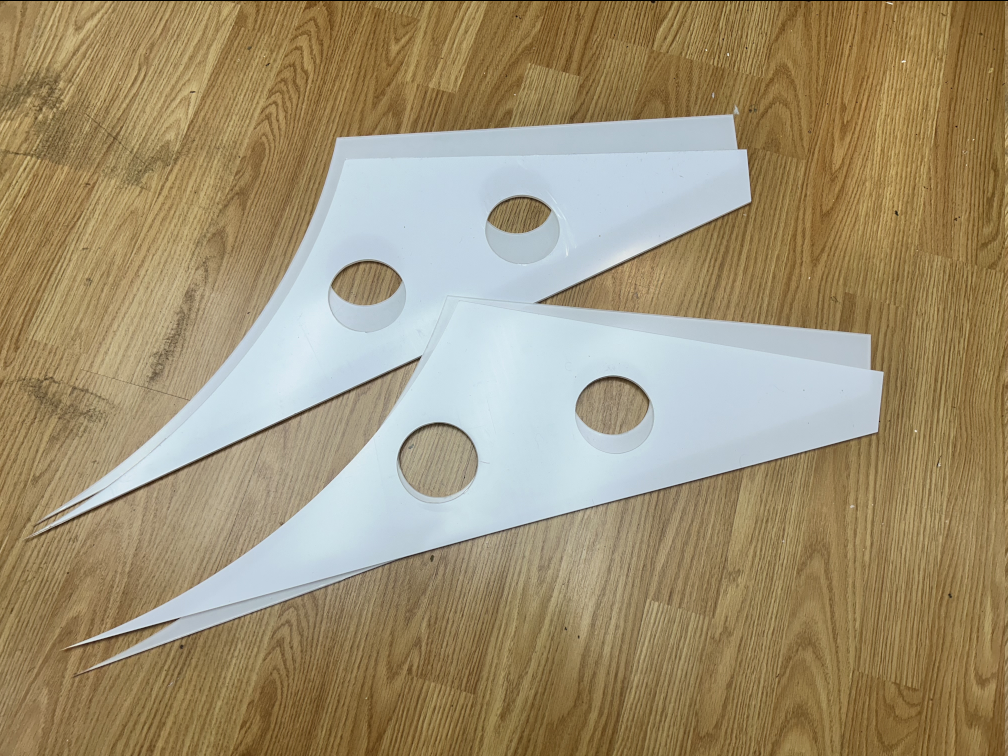

Finally received my laser cut parts for the mandibles. I'm not sure where along the way this happened, but the radius for the joint along the hull waist isn't correct. It's correct in my CAD drawing so I think whomever cut these manually recreated the parts in whatever software they used to cut the material. It's not a big deal for me to fix, but it's just a pain when manufactures do this sort of thing. The last time I tried to have these done, the guy made two pair port sides instead of a pair each port and starboard. When I told him he couldn't understand what the problem was and was upset I wouldn't pay for the job.

Also, I found a hobby store in the US that is selling a correct 1/500 HYUGA kit but he refuses to ship into Canada because reasons. So to hell with that guy, I'll keep looking.

Also, I found a hobby store in the US that is selling a correct 1/500 HYUGA kit but he refuses to ship into Canada because reasons. So to hell with that guy, I'll keep looking.

TazMan2000

Master Member

Finally received my laser cut parts for the mandibles. I'm not sure where along the way this happened, but the radius for the joint along the hull waist isn't correct. It's correct in my CAD drawing so I think whomever cut these manually recreated the parts in whatever software they used to cut the material. It's not a big deal for me to fix, but it's just a pain when manufactures do this sort of thing. The last time I tried to have these done, the guy made two pair port sides instead of a pair each port and starboard. When I told him he couldn't understand what the problem was and was upset I wouldn't pay for the job.

Also, I found a hobby store in the US that is selling a correct 1/500 HYUGA kit but he refuses to ship into Canada because reasons. So to hell with that guy, I'll keep looking.

View attachment 1812604

I've had stuff laser cut before. The guy who did it for me said that he needed DXF format, which I provided. He imported my files and the software interpretted each of my lines and curves as segments, which apparently wasn't going to work. He spent a lot of time trying to fix it, even though I told him I could deal with the segments and I would just use a dremel tool to cut the extra stuff off.

Perhaps your curve was interpretted as a series of segments and the operator tried to fix it by joining them together and thusly inadvertently changing the curvature.

TazMan2000

PMed you.Finally received my laser cut parts for the mandibles. I'm not sure where along the way this happened, but the radius for the joint along the hull waist isn't correct. It's correct in my CAD drawing so I think whomever cut these manually recreated the parts in whatever software they used to cut the material. It's not a big deal for me to fix, but it's just a pain when manufactures do this sort of thing. The last time I tried to have these done, the guy made two pair port sides instead of a pair each port and starboard. When I told him he couldn't understand what the problem was and was upset I wouldn't pay for the job.

Also, I found a hobby store in the US that is selling a correct 1/500 HYUGA kit but he refuses to ship into Canada because reasons. So to hell with that guy, I'll keep looking.

Similar threads

- Replies

- 2

- Views

- 320

- Replies

- 1

- Views

- 266

- Replies

- 0

- Views

- 234