TheoJones

New Member

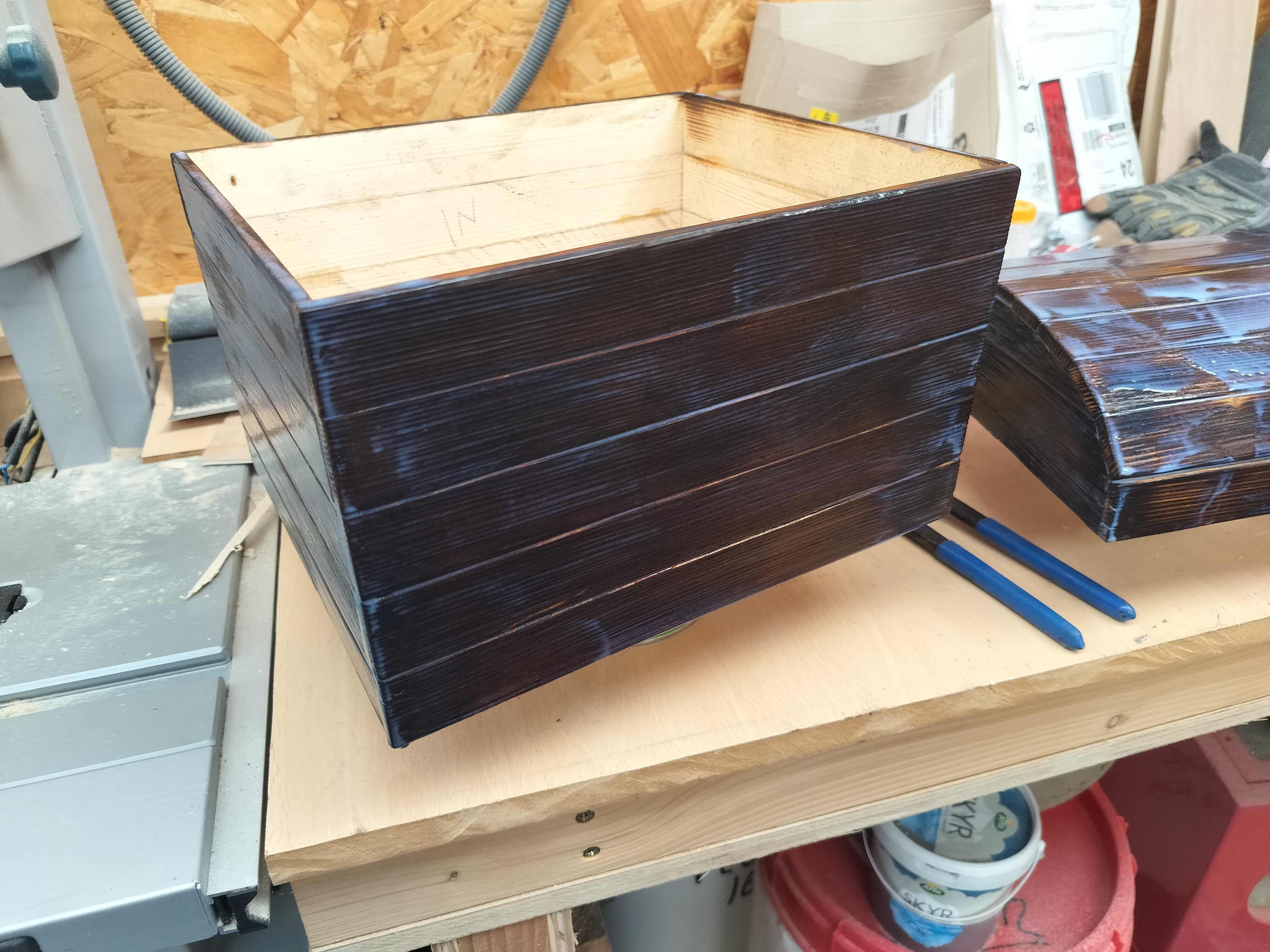

I am building a small (but functional) model of Terry Pratchett's Luggage as a gift. The case is a fairly simply wooden box, flame treated and varnished -

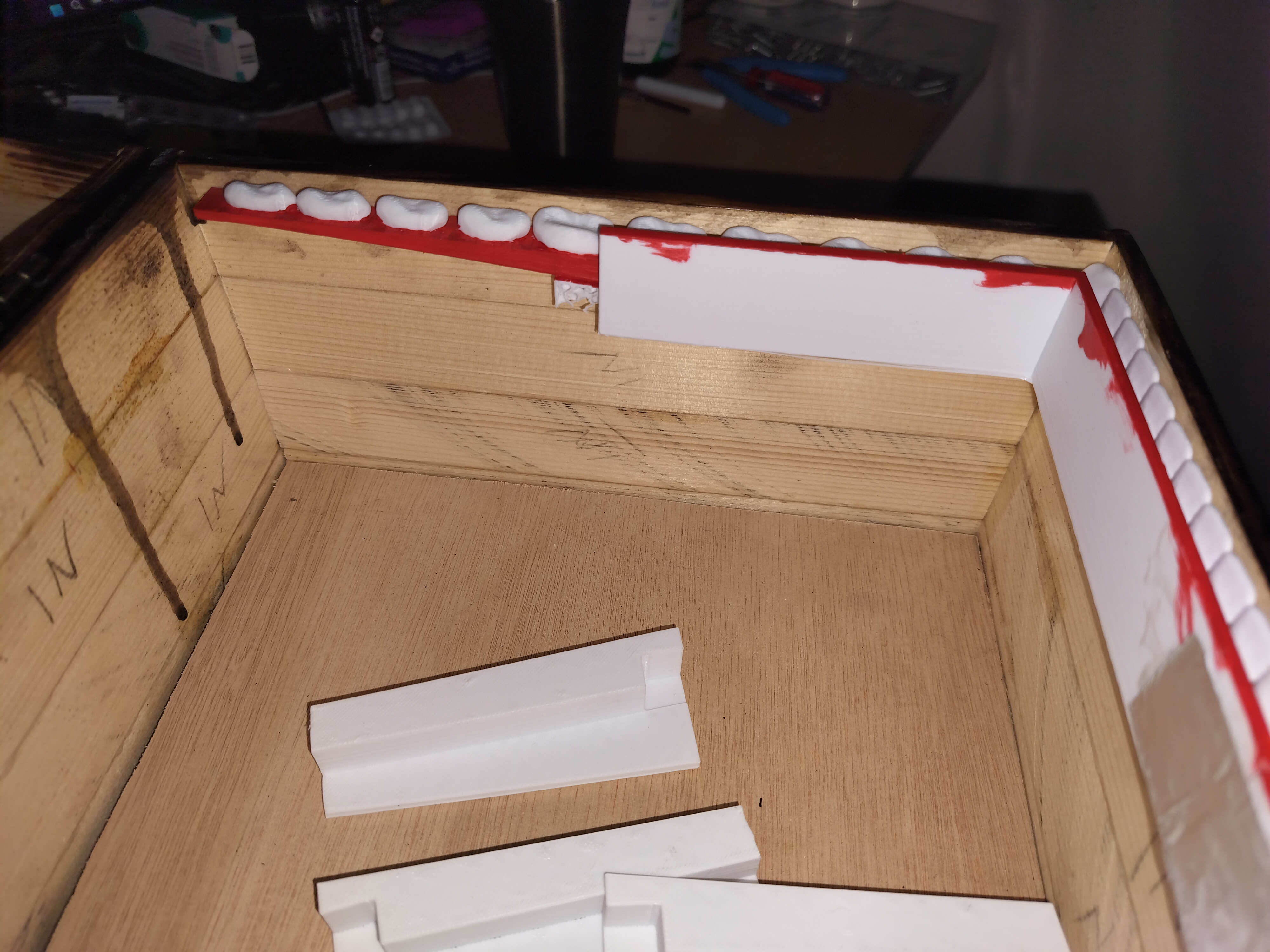

My vision is to have the luggage able to do two key things; I want the lid "mouth" to be able to open, "smile", chomp at something placed in it, and then close down.. so it has teeth:

The idea is that the teeth are concealed inside the lid and base when the lid is closed - the lid being opened by an arduino/stepper motor combo using a simple lever arm. with that in mind, there's a support structure around the lip;

part of the support is not in place for clarity here.

I had intended to drill some holes in the "jaws" and put compression springs inside - problem 1, these are insanely too strong - the weakest springs I can find pop the teeth "up"and the weight of the closed lid is not enough to compress them. I really don't want the stepper motor to have to force the lid closed... (my plan to prevent someone causing damage by pulling the lid open is to make opening the lid essentially a disconnected action - the motor lifts the lid far enough to animate it, but the owner could simply lift the lid - it's not connected.

My first question - what would you use for this lift mechanism? 3D printed flexure? a very light spring steel leaf?

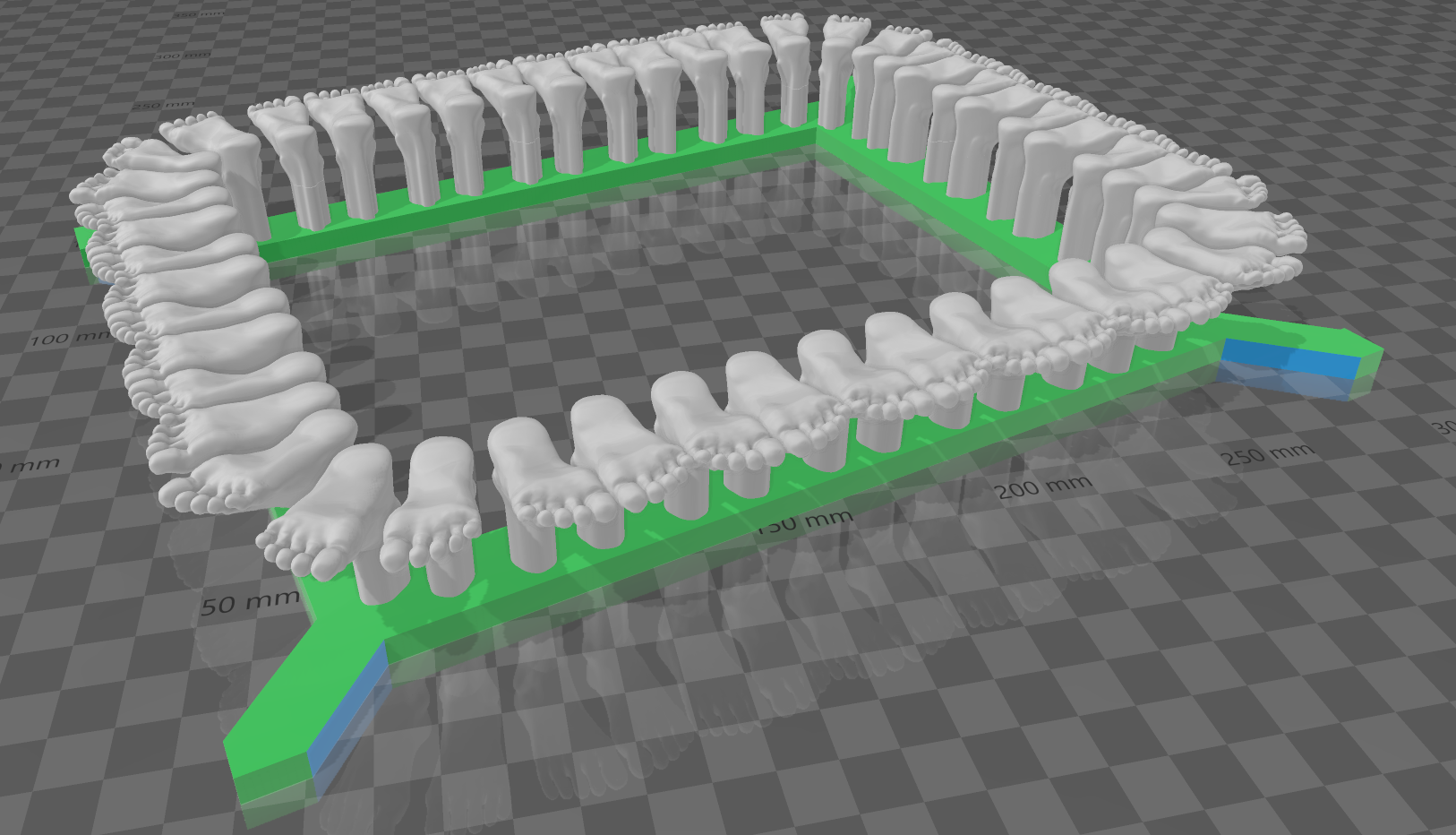

Once I have solved the teeth problem, I move to the feet, and am currently thinking a 3D printed scissor lift to allow the box to move between two positions - "sitting", where the box is on the ground and the feet are hidden, or "standing" where the box is supported by a ring of feet;

I think that's a safer proposition, as there are a good set of scissor lift platforms on thingiverse.

I am hoping that this is the correct forum.

Comments and Suggestions welcome

My vision is to have the luggage able to do two key things; I want the lid "mouth" to be able to open, "smile", chomp at something placed in it, and then close down.. so it has teeth:

The idea is that the teeth are concealed inside the lid and base when the lid is closed - the lid being opened by an arduino/stepper motor combo using a simple lever arm. with that in mind, there's a support structure around the lip;

part of the support is not in place for clarity here.

I had intended to drill some holes in the "jaws" and put compression springs inside - problem 1, these are insanely too strong - the weakest springs I can find pop the teeth "up"and the weight of the closed lid is not enough to compress them. I really don't want the stepper motor to have to force the lid closed... (my plan to prevent someone causing damage by pulling the lid open is to make opening the lid essentially a disconnected action - the motor lifts the lid far enough to animate it, but the owner could simply lift the lid - it's not connected.

My first question - what would you use for this lift mechanism? 3D printed flexure? a very light spring steel leaf?

Once I have solved the teeth problem, I move to the feet, and am currently thinking a 3D printed scissor lift to allow the box to move between two positions - "sitting", where the box is on the ground and the feet are hidden, or "standing" where the box is supported by a ring of feet;

I think that's a safer proposition, as there are a good set of scissor lift platforms on thingiverse.

I am hoping that this is the correct forum.

Comments and Suggestions welcome