You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edraven99's Collection Tread - Long Overdue Updates

- Thread starter Edraven99

- Start date

Re: Edraven99's Real Parts Lightsaber Build Thread

I gotta say, I like the look of those O-rings, original or not. They almost look like they're meant to be there. Like Roy said, very maker-like. Thumbs up!

I gotta say, I like the look of those O-rings, original or not. They almost look like they're meant to be there. Like Roy said, very maker-like. Thumbs up!

Re: Edraven99's Real Parts Lightsaber Build Thread

Hi David,

They do sell square profile O rings. Just another option for you.

http://www.theoringstore.com/index.php?main_page=index&cPath=367_98

Hi David,

They do sell square profile O rings. Just another option for you.

http://www.theoringstore.com/index.php?main_page=index&cPath=367_98

Sym-Cha

Master Member

Re: Edraven99's Real Parts Lightsaber Build Thread

@ Marv ... yeah I too think that MPP almost has a two tone paint scheme : black and white :lol

@ teecrooz great find

@ Edraven99 those O-ring look good enough. Your clamp seems to have a red hue compared

to Parks black sleeve, correct?

Chaim

@ Marv ... yeah I too think that MPP almost has a two tone paint scheme : black and white :lol

@ teecrooz great find

@ Edraven99 those O-ring look good enough. Your clamp seems to have a red hue compared

to Parks black sleeve, correct?

Chaim

Re: Edraven99's Real Parts Lightsaber Build Thread

"I'm going to open a store that sells just o-rings"

"But... What else?... I mean you can't just sell o-rings... Maybe open a plumbing parts store?"

"Nope! O-rings! Rubber gold! That's the ticket!"

Hi David,

They do sell square profile O rings. Just another option for you.

http://www.theoringstore.com/index.php?main_page=index&cPath=367_98

"I'm going to open a store that sells just o-rings"

"But... What else?... I mean you can't just sell o-rings... Maybe open a plumbing parts store?"

"Nope! O-rings! Rubber gold! That's the ticket!"

Re: Edraven99's Real Parts Lightsaber Build Thread

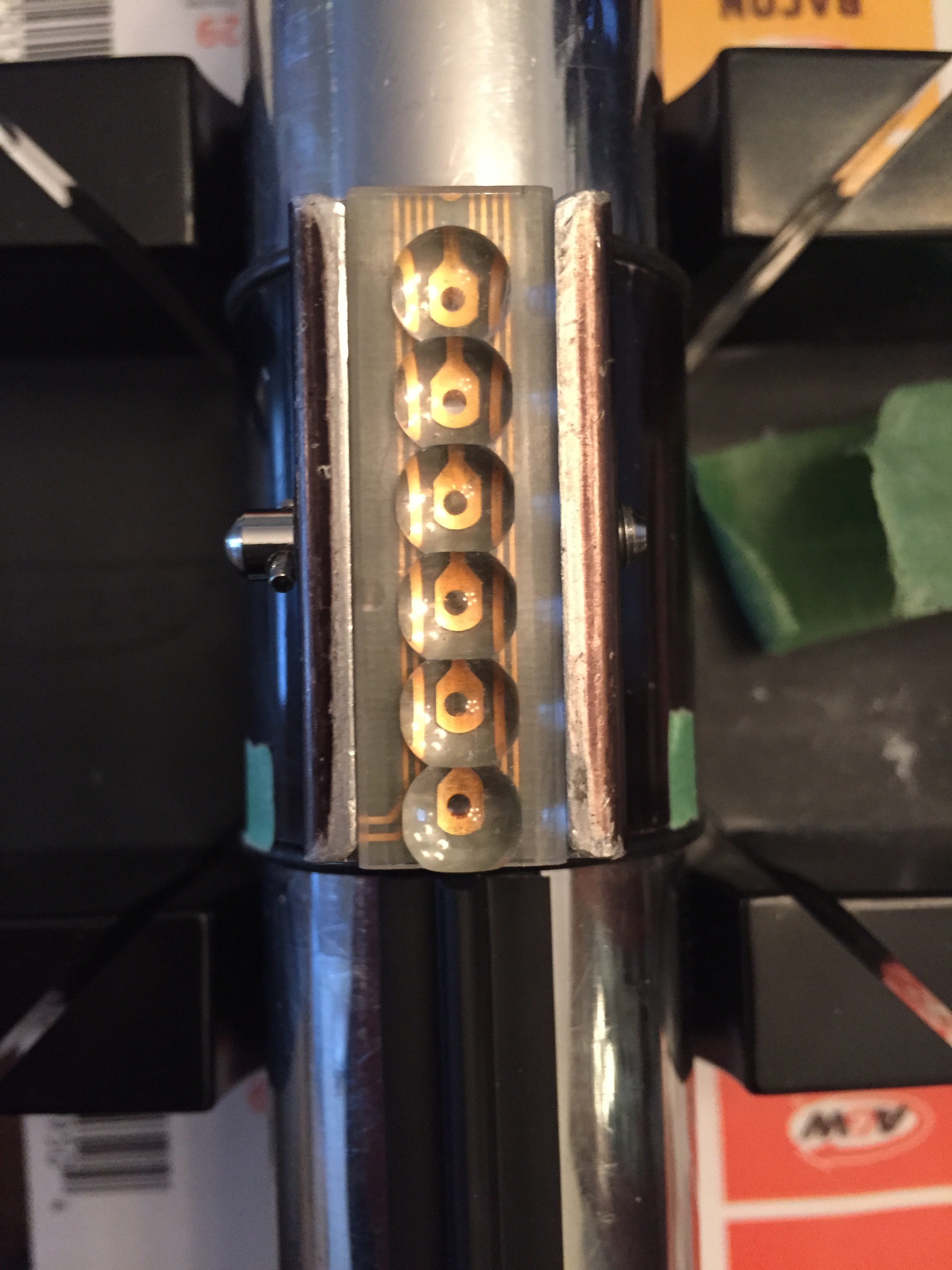

Yup... the rings wrap fully around and to be completely honest, they do look a tad odd because they are essentially black bands floating across the gap.

It won't be a big issue with the back one since the T-track will cover it up. What I'm hoping is that when I put in the bubbles, it will be less noticeable.

I'll try to take a picture tonight and post it up...

That's good idea... I was thinking they might be a tad too glossy myself! Thanks Roy!

Sort of... it's that tinge that black starts to get as it starts to fade... like when you have a black marker and it starts to dry out and what's coming out isn't quite black anymore...

Nice find Chris! Though I was under the impression that the raised ridges on the MPP clamp sleeve were more rounded than square. The ridges on my MR limited ANH Vader lightsaber are rounded... which is also why I was a little disappointed by the Parks replica sleeve because it looked a little too square...

Can Chaim or scottjua or parfaitelumiere or someone else who has/had a real MPP chime in and confirm?

The O rings actually look better, in my taste. Do they wrap fully around the tube, and if so, how does the bubble-strip side look with a continuous black rim behind it? Since the sleeve stops before then

Yup... the rings wrap fully around and to be completely honest, they do look a tad odd because they are essentially black bands floating across the gap.

It won't be a big issue with the back one since the T-track will cover it up. What I'm hoping is that when I put in the bubbles, it will be less noticeable.

I'll try to take a picture tonight and post it up...

You might try to sand them a bit, so they're not too glossy.

Roy

That's good idea... I was thinking they might be a tad too glossy myself! Thanks Roy!

Your clamp seems to have a red hue compared to Parks black sleeve, correct?

Sort of... it's that tinge that black starts to get as it starts to fade... like when you have a black marker and it starts to dry out and what's coming out isn't quite black anymore...

Hi David,

They do sell square profile O rings. Just another option for you.

http://www.theoringstore.com/index.php?main_page=index&cPath=367_98

Nice find Chris! Though I was under the impression that the raised ridges on the MPP clamp sleeve were more rounded than square. The ridges on my MR limited ANH Vader lightsaber are rounded... which is also why I was a little disappointed by the Parks replica sleeve because it looked a little too square...

Can Chaim or scottjua or parfaitelumiere or someone else who has/had a real MPP chime in and confirm?

Last edited by a moderator:

Re: Edraven99's Real Parts Lightsaber Build Thread

The parks are quite good, really close, even not as rounded as real stuff, but it's not very noticeable.

bout the red hue on clamp ring, yes, some real stuff has red hue on aluminum anodisation, unlike the parks or other replicas who have painted steel clamps.

I was talking about a real-replica mpp and it's variation thread, but still didn't make it...

The parks are quite good, really close, even not as rounded as real stuff, but it's not very noticeable.

bout the red hue on clamp ring, yes, some real stuff has red hue on aluminum anodisation, unlike the parks or other replicas who have painted steel clamps.

I was talking about a real-replica mpp and it's variation thread, but still didn't make it...

Re: Edraven99's Real Parts Lightsaber Build Thread

My real sleeve is squared on the inside edge that touches the metal, and slightly rounded on the outside edge and top... so it looks mostly rounded.

oh and BTW,.... mine came with a cotter pin too... not the parks style pin.

My real sleeve is squared on the inside edge that touches the metal, and slightly rounded on the outside edge and top... so it looks mostly rounded.

oh and BTW,.... mine came with a cotter pin too... not the parks style pin.

Re: Edraven99's Real Parts Lightsaber Build Thread

Wow... that was a quick response... thanks guys!

So based on Chaim's picture (especially looking at the bottom right corner ridge) and Scott's observations, it does look like the the top of the ridge is rounded so it's more of s "U" shape... so I think that the round O-ring might be the way to go in this instance....

Wow... that was a quick response... thanks guys!

So based on Chaim's picture (especially looking at the bottom right corner ridge) and Scott's observations, it does look like the the top of the ridge is rounded so it's more of s "U" shape... so I think that the round O-ring might be the way to go in this instance....

Re: Edraven99's Real Parts Lightsaber Build Thread

Another quick update on the Vader MPP build (well actually I finished this off last weekend but I haven't had the chance to post it!)

Since I've been focusing on the clamp, I figured it was time to tackle the bubble strip.

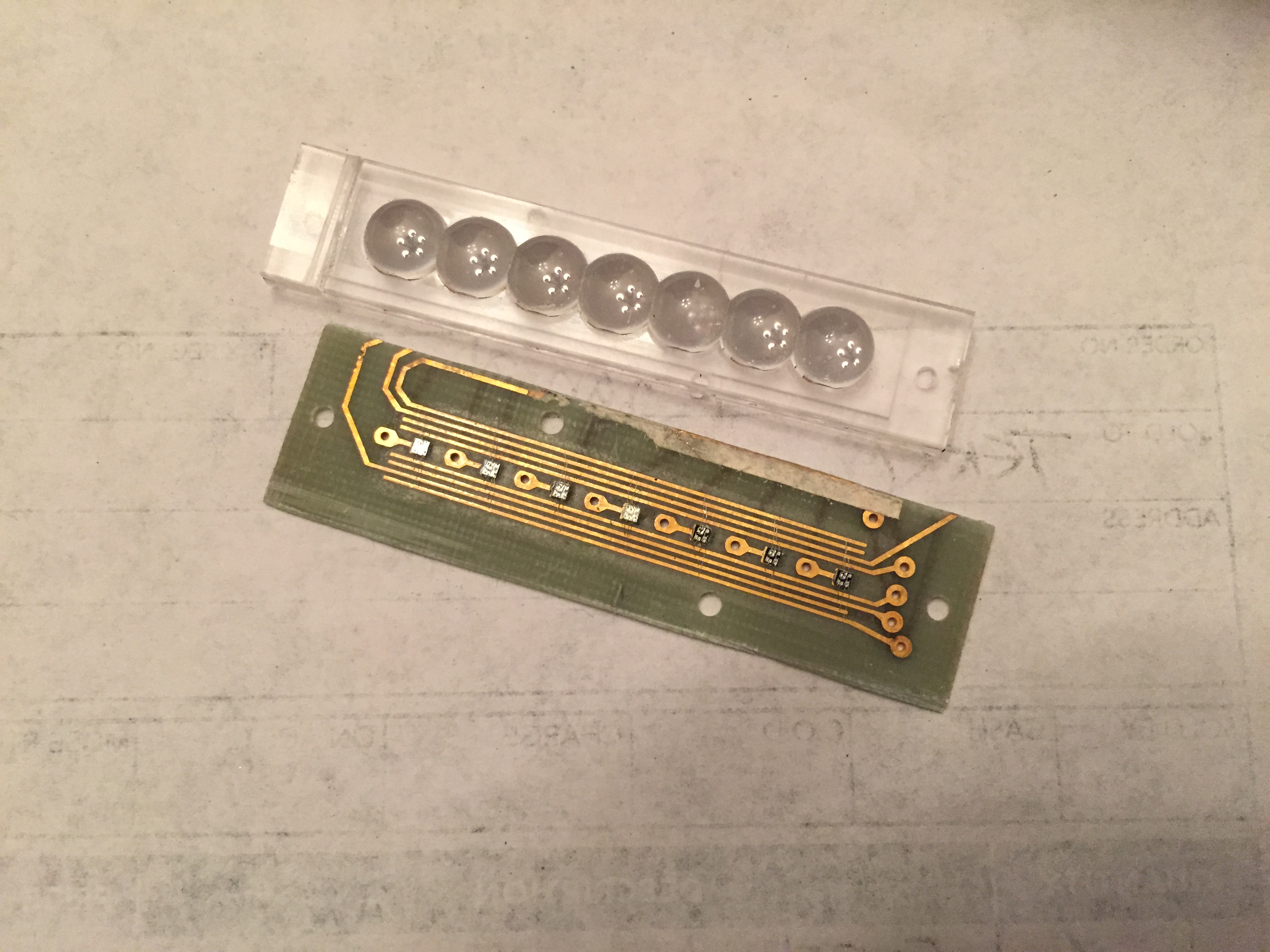

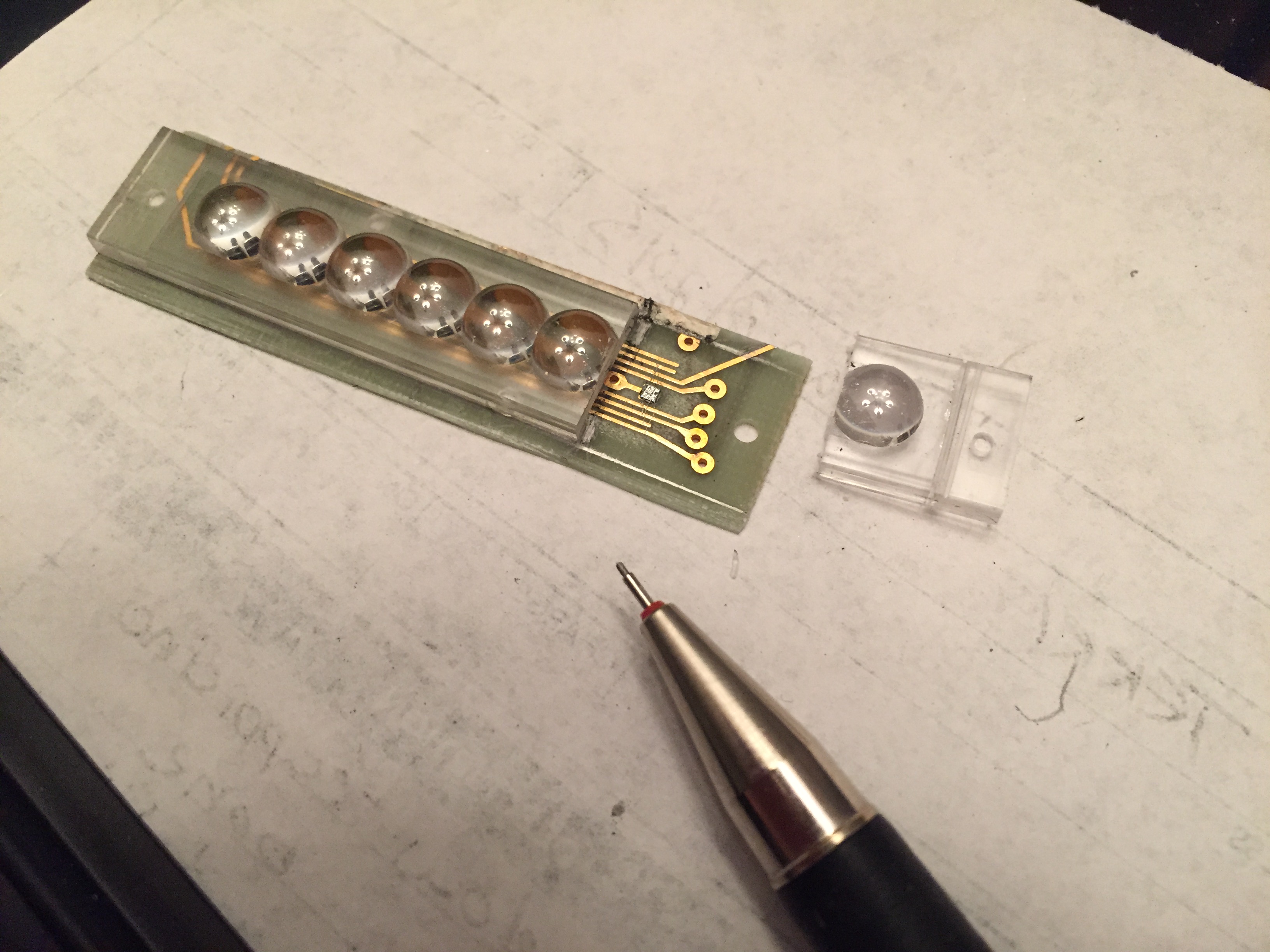

I started off first by taking the strip off the circuit board. For those of you two or three people on this board who have never done this before, it's a very easy thing to do. The strip itself has pegs that hold it to the board and those pegs are secured by a very thin layer of melted plastic. So all you have to do to remove the strip from the board is to pry off that melted plastic:

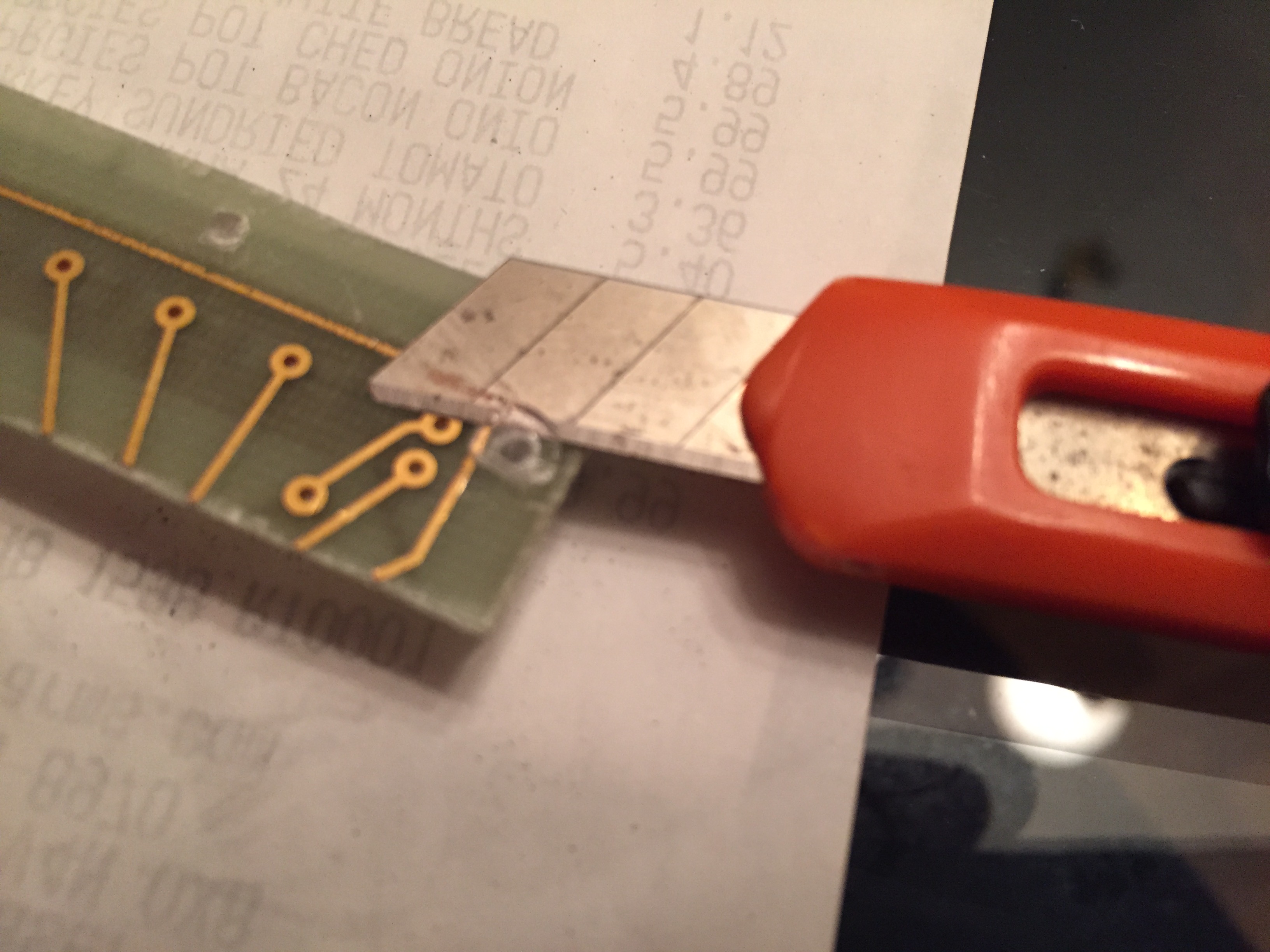

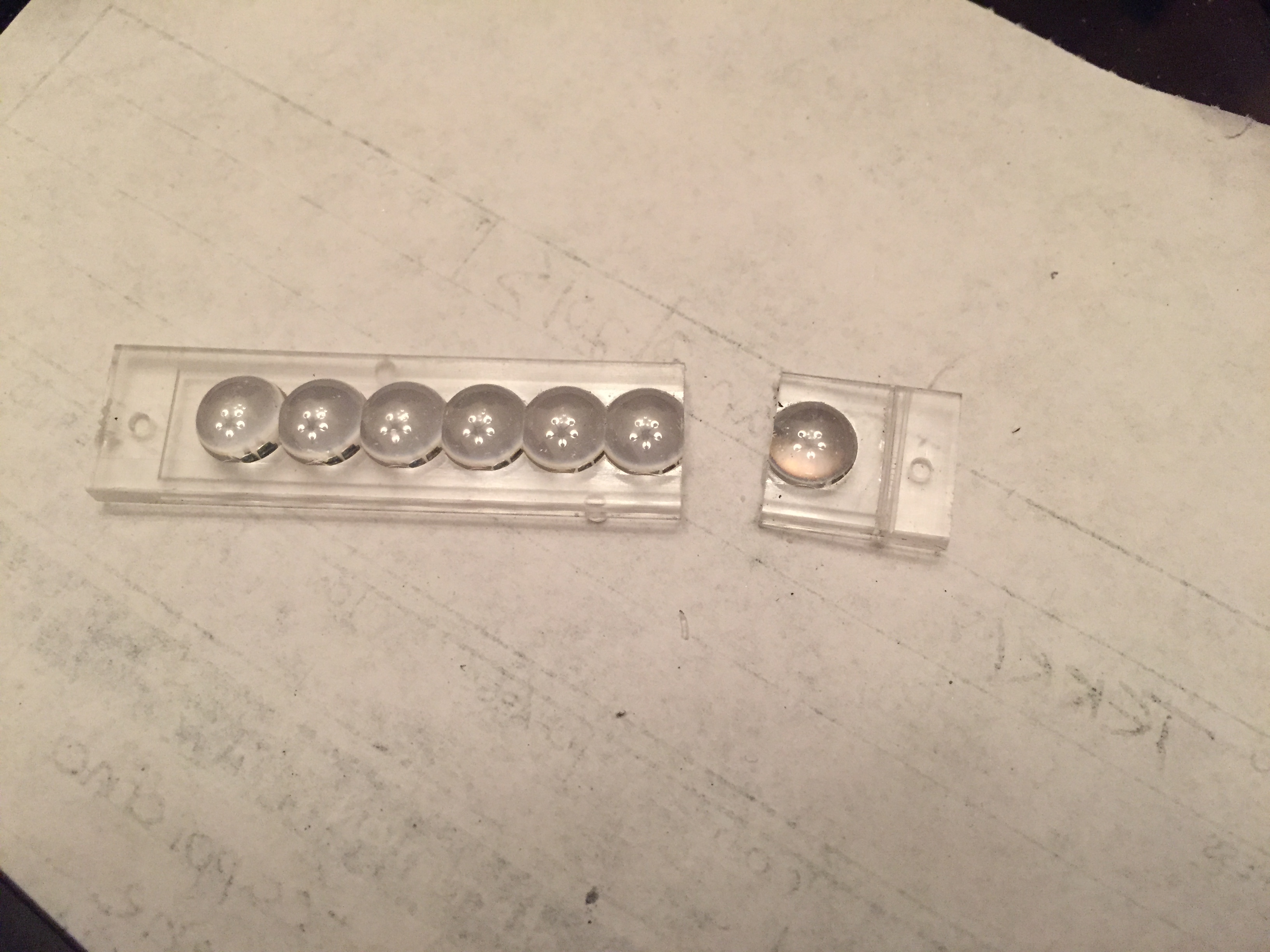

Next, because this is a Vader build, I needed to trim off one of the bubbles. Again, fairly easily done with my Exacto saw and mitre box though the plastic of the strip was a little denser than I was anticipating:

Again, since this is a Vader build, I still needed that circuit board, so I reattached the cut bubble strip to the board and used my trusty pencil to outline where I needed to cut.

A word of advice to those attempting this build in he future, that circuit board is deceptively tough despite how thin it is. I originally used a fine-toothed saw and it took me forever and a more than a bit of elbow grease to to cut through it. Once I switched over to a coarser saw, it was a lot easier.

The next step then was to file off those pegs along with the small ledges that run along the length of the the bubble strip. I was originally hoping that I wouldn't have to file off the ledges, but they definitely make the strip too thick for the clamp.

This was done by carefully running the entire length of the strip across the surface of a flat file. Every now and then I flipped the orientation around just to make sure I was applying the same amount of pressure across the entire length of the strip so that I could file it down as evenly as possible.

And here's the end result:

I didn't realize it until I was looking at Kurtyboy's Vader MPP ESB, but the circuit board needs to be turned around in order to achieve that accurate "tear-drop" look.

Now my bubble strip isn't completely 100% accurate, in order for it to be, the bubbles need to go under the clamp. But as you can see from the third picture, I either need to really file down the bubble strip, or take a pair of pliers to the clamp and really crank on it like it looks like the original prop makers did in order to make it all fit, which I don't think I'm inclined to do.

What do you guys think?

Another quick update on the Vader MPP build (well actually I finished this off last weekend but I haven't had the chance to post it!)

Since I've been focusing on the clamp, I figured it was time to tackle the bubble strip.

I started off first by taking the strip off the circuit board. For those of you two or three people on this board who have never done this before, it's a very easy thing to do. The strip itself has pegs that hold it to the board and those pegs are secured by a very thin layer of melted plastic. So all you have to do to remove the strip from the board is to pry off that melted plastic:

Next, because this is a Vader build, I needed to trim off one of the bubbles. Again, fairly easily done with my Exacto saw and mitre box though the plastic of the strip was a little denser than I was anticipating:

Again, since this is a Vader build, I still needed that circuit board, so I reattached the cut bubble strip to the board and used my trusty pencil to outline where I needed to cut.

A word of advice to those attempting this build in he future, that circuit board is deceptively tough despite how thin it is. I originally used a fine-toothed saw and it took me forever and a more than a bit of elbow grease to to cut through it. Once I switched over to a coarser saw, it was a lot easier.

The next step then was to file off those pegs along with the small ledges that run along the length of the the bubble strip. I was originally hoping that I wouldn't have to file off the ledges, but they definitely make the strip too thick for the clamp.

This was done by carefully running the entire length of the strip across the surface of a flat file. Every now and then I flipped the orientation around just to make sure I was applying the same amount of pressure across the entire length of the strip so that I could file it down as evenly as possible.

And here's the end result:

I didn't realize it until I was looking at Kurtyboy's Vader MPP ESB, but the circuit board needs to be turned around in order to achieve that accurate "tear-drop" look.

Now my bubble strip isn't completely 100% accurate, in order for it to be, the bubbles need to go under the clamp. But as you can see from the third picture, I either need to really file down the bubble strip, or take a pair of pliers to the clamp and really crank on it like it looks like the original prop makers did in order to make it all fit, which I don't think I'm inclined to do.

What do you guys think?

Last edited:

Re: Edraven99's Real Parts Lightsaber Build Thread

good bubble strip and right version, however you will have to make grooves on the bubble itself so it will fill the room in the clamp.

I have to do same on mine but still didn't think about it, it's the only thing to do on my vader saber then it will be finished.

About the clamp I would better choose the parks sleeve.

good bubble strip and right version, however you will have to make grooves on the bubble itself so it will fill the room in the clamp.

I have to do same on mine but still didn't think about it, it's the only thing to do on my vader saber then it will be finished.

About the clamp I would better choose the parks sleeve.

Re: Edraven99's Real Parts Lightsaber Build Thread

Almost there on the Vader!

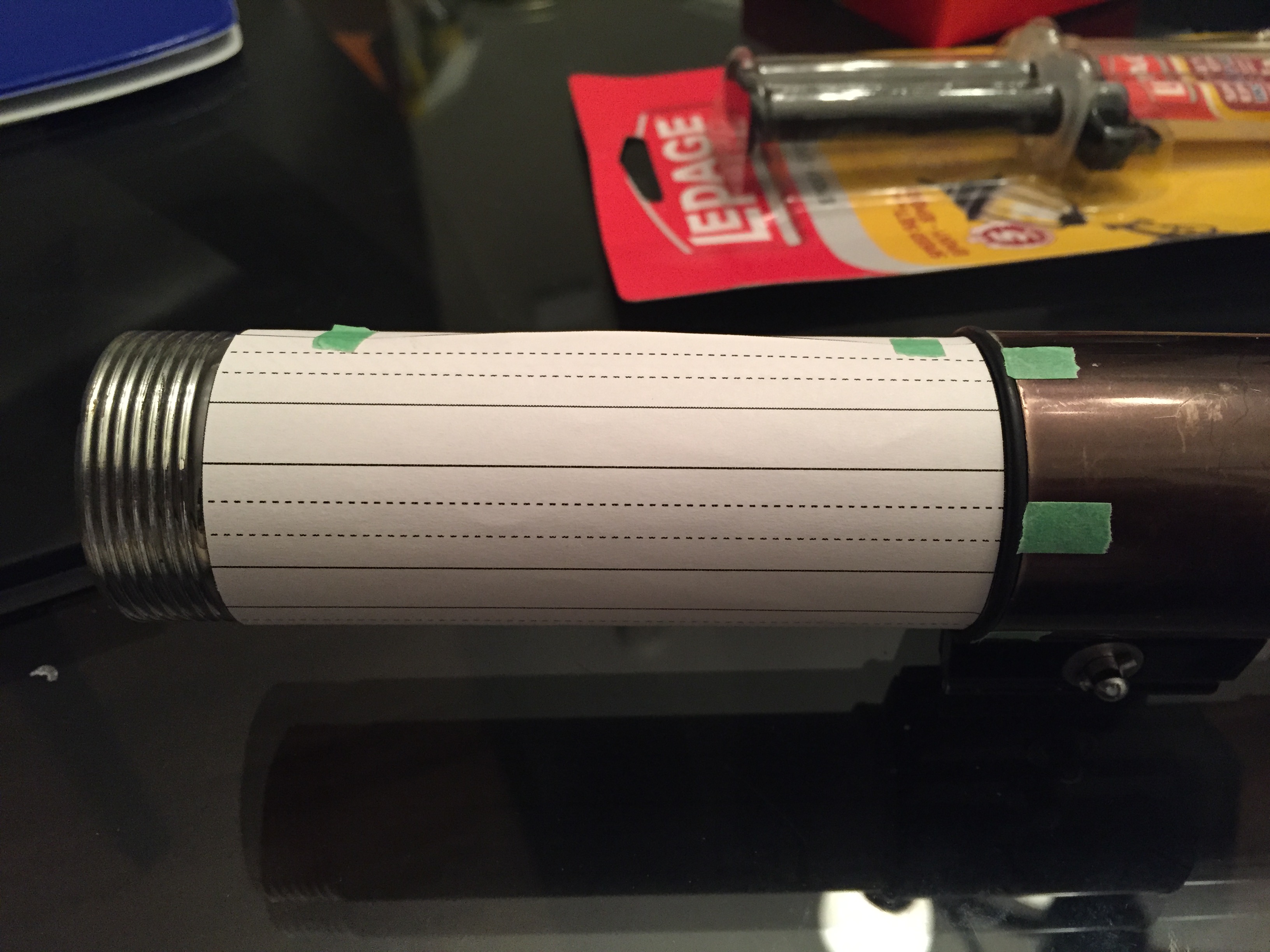

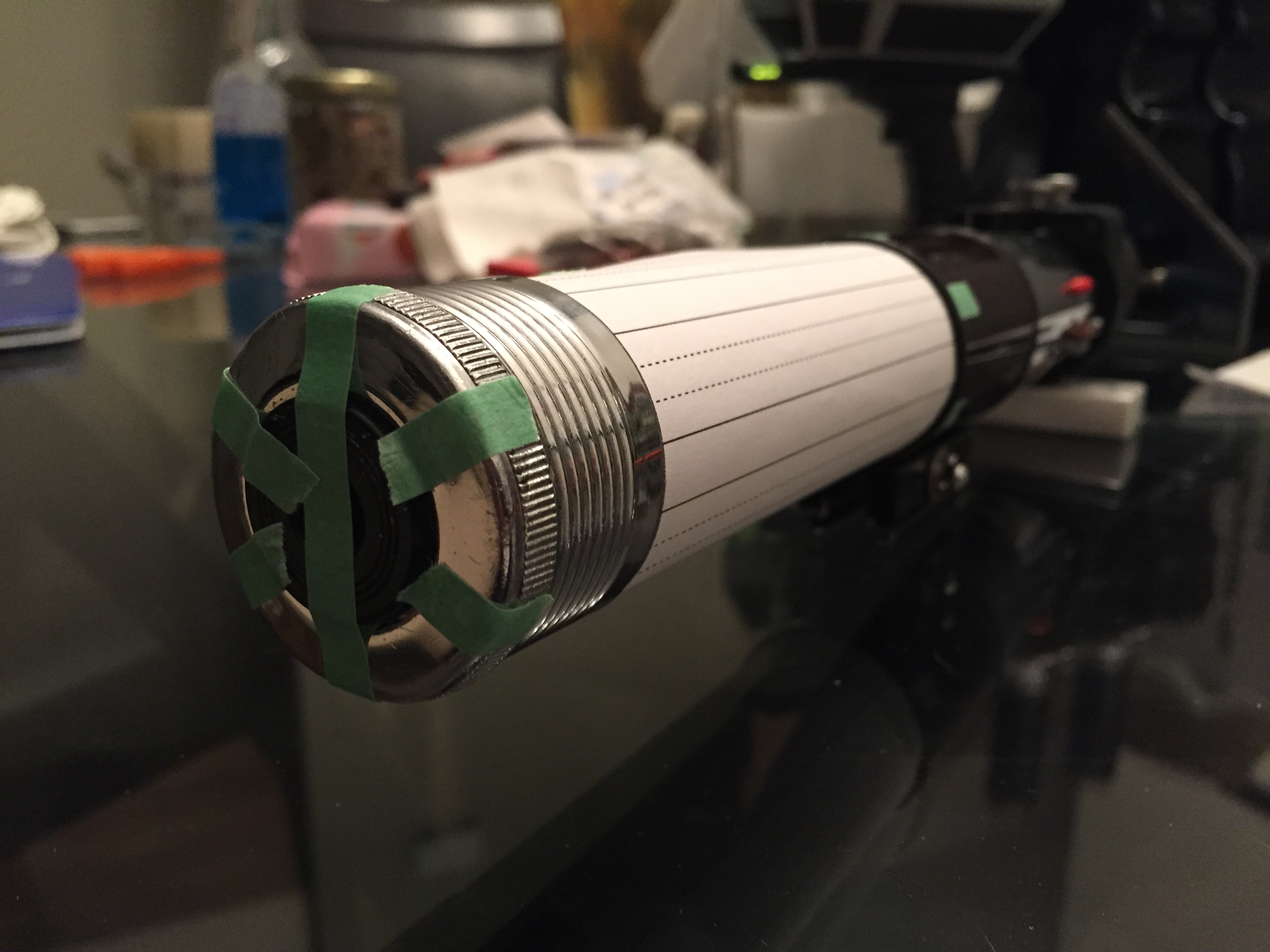

Next of course was gluing on the T-tracks. Ok... this was a bigger pain in the ass than I was anticipating....

Because the the flash tube is a smooth rounded surface, the T-tracks had a tendency of sliding when trying to line them up, so the only thing you could do at times was a visual alignment. And there really isn't a way of clamping the track down to the tube to try and get a tighter seal while the epoxy was setting; anything I tried - rubber bands, padded c-clamp, etc. - just pulled the track out of alignment as soon as any pressure was applied.

This is especially problematic on the MPP because of the raised end cap. I was hoping to try to minimize the gap between the raised edge of the cap and the tube itself as much as possible... but in the end all I could settle for was to line everything up and just let the epoxy cure the tracks in place.

I started off by downloading a grip template off of PoSW and using that and some painters tape to give a rough visual as to where all the grips should go. Then it was simply a case of epoxying everything into place:

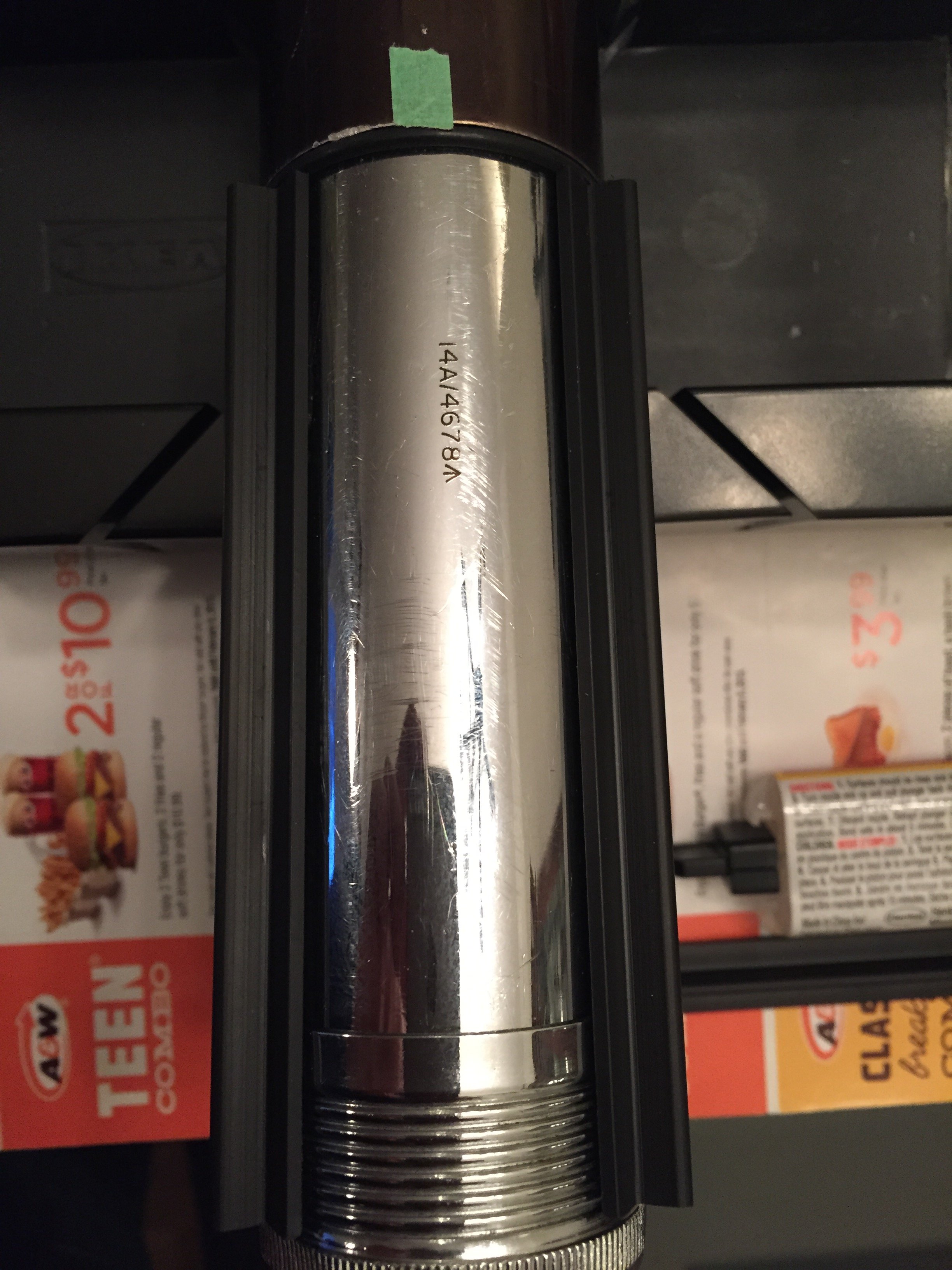

That last top T-track was the one that I hated doing the most. Not because it was more difficult or anything like that, but it covered up the cool military serial number on my MPP... but there was nothing that could be done about it. But with that last track in place, T-tracks are done!

Only one last thing to do and one last bit of advice needed from all of you on this build:

Stick with the original but incorrect two-step shroud keeping everything as original parts as possible, or go with the replica Parks shroud which would be more accurate prop wise?

What say you all?

Almost there on the Vader!

Next of course was gluing on the T-tracks. Ok... this was a bigger pain in the ass than I was anticipating....

Because the the flash tube is a smooth rounded surface, the T-tracks had a tendency of sliding when trying to line them up, so the only thing you could do at times was a visual alignment. And there really isn't a way of clamping the track down to the tube to try and get a tighter seal while the epoxy was setting; anything I tried - rubber bands, padded c-clamp, etc. - just pulled the track out of alignment as soon as any pressure was applied.

This is especially problematic on the MPP because of the raised end cap. I was hoping to try to minimize the gap between the raised edge of the cap and the tube itself as much as possible... but in the end all I could settle for was to line everything up and just let the epoxy cure the tracks in place.

I started off by downloading a grip template off of PoSW and using that and some painters tape to give a rough visual as to where all the grips should go. Then it was simply a case of epoxying everything into place:

That last top T-track was the one that I hated doing the most. Not because it was more difficult or anything like that, but it covered up the cool military serial number on my MPP... but there was nothing that could be done about it. But with that last track in place, T-tracks are done!

Only one last thing to do and one last bit of advice needed from all of you on this build:

Stick with the original but incorrect two-step shroud keeping everything as original parts as possible, or go with the replica Parks shroud which would be more accurate prop wise?

What say you all?

Re: Edraven99's Real Parts Lightsaber Build Thread

Nice work David!!

I think you did an excellent job on gluing the T-tracks!

I would go for the vintage part; has a better finish imo.

Or you keep them loosely connected until you find a better part

Roy

www.wannawanga.com

Nice work David!!

I think you did an excellent job on gluing the T-tracks!

I would go for the vintage part; has a better finish imo.

Or you keep them loosely connected until you find a better part

Roy

www.wannawanga.com

Sym-Cha

Master Member

Re: Edraven99's Real Parts Lightsaber Build Thread

Go for the vintage for now since that Parks has the D-ring in the wrong place ... here's how it looks much better on the original :

behind the screw ... and best to try this for your vintage shroud as well. Carefully drill a smaller hole than you actually need and

use a small file to open the hole more gradually until the D fits

Chaim

Go for the vintage for now since that Parks has the D-ring in the wrong place ... here's how it looks much better on the original :

behind the screw ... and best to try this for your vintage shroud as well. Carefully drill a smaller hole than you actually need and

use a small file to open the hole more gradually until the D fits

Chaim

Re: Edraven99's Real Parts Lightsaber Build Thread

I think I recall a post where either you or parfaitelumiere mentioned that the D-ring that Parks uses is incorrect?b Or it might have been a comment you made in intwenothor's Vader build on dented helmet...

Any idea as to where I can get an accurate one?

- - - Updated - - -

Thanks Roy! I forgot to tell you that I got my Kobold clip and rivets... finishing off my Luke ESB Graflex conversion will be next up to bat!

Go for the vintage for now since that Parks has the D-ring in the wrong place ... here's how it looks much better on the original :

http://i833.photobucket.com/albums/zz258/Sym-Cha/MPP05.jpg

behind the screw ... and best to try this for your vintage shroud as well. Carefully drill a smaller hole than you actually need and

use a small file to open the hole more gradually until the D fits

Chaim

I think I recall a post where either you or parfaitelumiere mentioned that the D-ring that Parks uses is incorrect?b Or it might have been a comment you made in intwenothor's Vader build on dented helmet...

Any idea as to where I can get an accurate one?

- - - Updated - - -

Nice work David!!

I think you did an excellent job on gluing the T-tracks!

I would go for the vintage part; has a better finish imo.

Or you keep them loosely connected until you find a better part

Roy

www.wannawanga.com

Thanks Roy! I forgot to tell you that I got my Kobold clip and rivets... finishing off my Luke ESB Graflex conversion will be next up to bat!

Last edited by a moderator:

Re: Edraven99's Real Parts Lightsaber Build Thread

I'd try to repaint the parks one... I need to research the crinkle finish though, as I know nothing about it. But at least doing that you have the option... and can re-drill the parks hole for the D ring.

I was also thinking about the T tracks... I was going to use a 1/2" strip of VHB 5 mil tape to hold them in place while the epoxy cured. They don't need the whole length exoxied, and the fhb holds super mega strong anyway... Actually... maybe the tape is enough on it's own. Hmmmm

I'd try to repaint the parks one... I need to research the crinkle finish though, as I know nothing about it. But at least doing that you have the option... and can re-drill the parks hole for the D ring.

I was also thinking about the T tracks... I was going to use a 1/2" strip of VHB 5 mil tape to hold them in place while the epoxy cured. They don't need the whole length exoxied, and the fhb holds super mega strong anyway... Actually... maybe the tape is enough on it's own. Hmmmm

Sym-Cha

Master Member

Re: Edraven99's Real Parts Lightsaber Build Thread

Well . . . if you like intwenothor's MPP build on the dented helmet of which I'm not a member by the way . . . that's one of my last 'matt' D-rings

http://www.thedentedhelmet.com/f45/darth-vader-esb-lightsaber-mpp-build-51309/ ... I have one left. Although a shiny one could be used as well as I did on my own MPP :

I have several of those left too but they need to be widened a bit to look as in above picture

Chaim

Well . . . if you like intwenothor's MPP build on the dented helmet of which I'm not a member by the way . . . that's one of my last 'matt' D-rings

http://www.thedentedhelmet.com/f45/darth-vader-esb-lightsaber-mpp-build-51309/ ... I have one left. Although a shiny one could be used as well as I did on my own MPP :

I have several of those left too but they need to be widened a bit to look as in above picture

Chaim

Similar threads

- Replies

- 3

- Views

- 423