(Click for a 4K version)

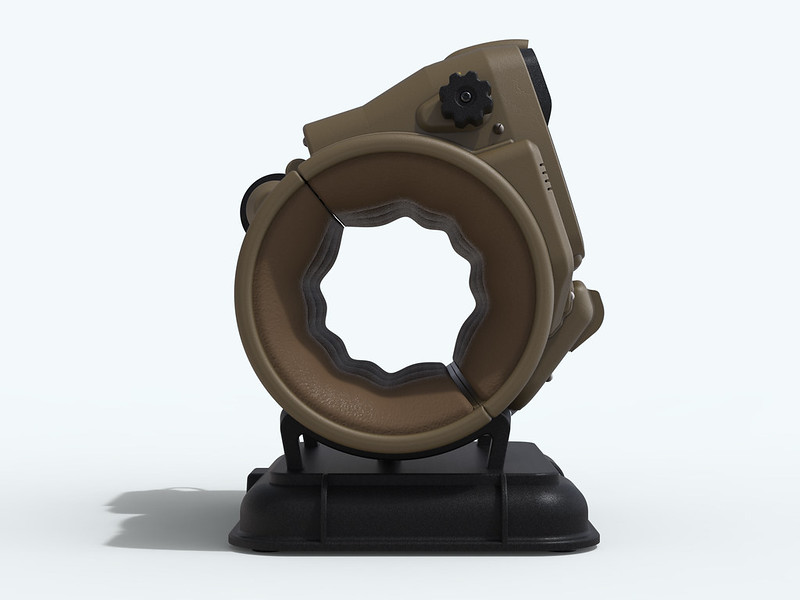

Time for another sweet 3D render. I will probably drop a few more of these in the next few days. (I let them run for 8 hours each)

This is as close to perfect as I can get on the design in CAD. All changes now will be pushed either by the electrical design, or by changes from a prototype build.

I have ordered a bunch of electronic parts and development boards. However I plan on finishing the dosimeter first.

I have had an offer from a fan of the project to 3D print all the parts in used/old SLS powder at no cost. This will be a huge help to the project. I will post the name of the company once the parts arrive (No exact time-frame). They will become the prototype parts.

I still have lots of small prototyping to do, such as all the laser-cut parts.

I have to figure out the best method to make the rad guage and radio dial faces. The Rad gauge might be just fine using a high quality print on card stock. But the Radio readout needs to be 100% opaque. For this I plan on painting a piece of diffused acrylic with black paint, and then laser-etching the artwork into the part.

For all the decals, I am going to try using dry erase transfers. (I don't like the outline that is visible around wet-transfer decals.) I also need to try out Rub-n-Buff for the metal areas, or that popular chrome marker that is making the rounds on the RPF.

I am also split between making an aged Pip-Boy like in-game, or a brand-new Pip-Boy as shown in the render above.

Time for another sweet 3D render. I will probably drop a few more of these in the next few days. (I let them run for 8 hours each)

This is as close to perfect as I can get on the design in CAD. All changes now will be pushed either by the electrical design, or by changes from a prototype build.

I have ordered a bunch of electronic parts and development boards. However I plan on finishing the dosimeter first.

I have had an offer from a fan of the project to 3D print all the parts in used/old SLS powder at no cost. This will be a huge help to the project. I will post the name of the company once the parts arrive (No exact time-frame). They will become the prototype parts.

I still have lots of small prototyping to do, such as all the laser-cut parts.

I have to figure out the best method to make the rad guage and radio dial faces. The Rad gauge might be just fine using a high quality print on card stock. But the Radio readout needs to be 100% opaque. For this I plan on painting a piece of diffused acrylic with black paint, and then laser-etching the artwork into the part.

For all the decals, I am going to try using dry erase transfers. (I don't like the outline that is visible around wet-transfer decals.) I also need to try out Rub-n-Buff for the metal areas, or that popular chrome marker that is making the rounds on the RPF.

I am also split between making an aged Pip-Boy like in-game, or a brand-new Pip-Boy as shown in the render above.