Archive&Future

Sr Member

Hey everyone,

I've been inactive on here for a long time!

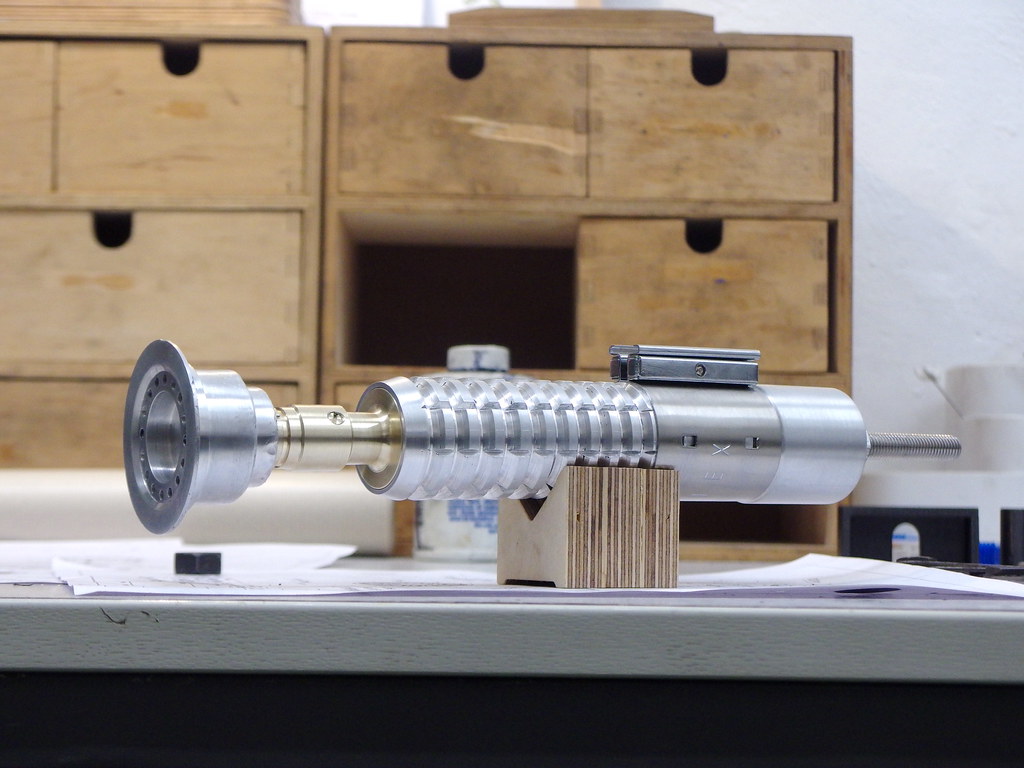

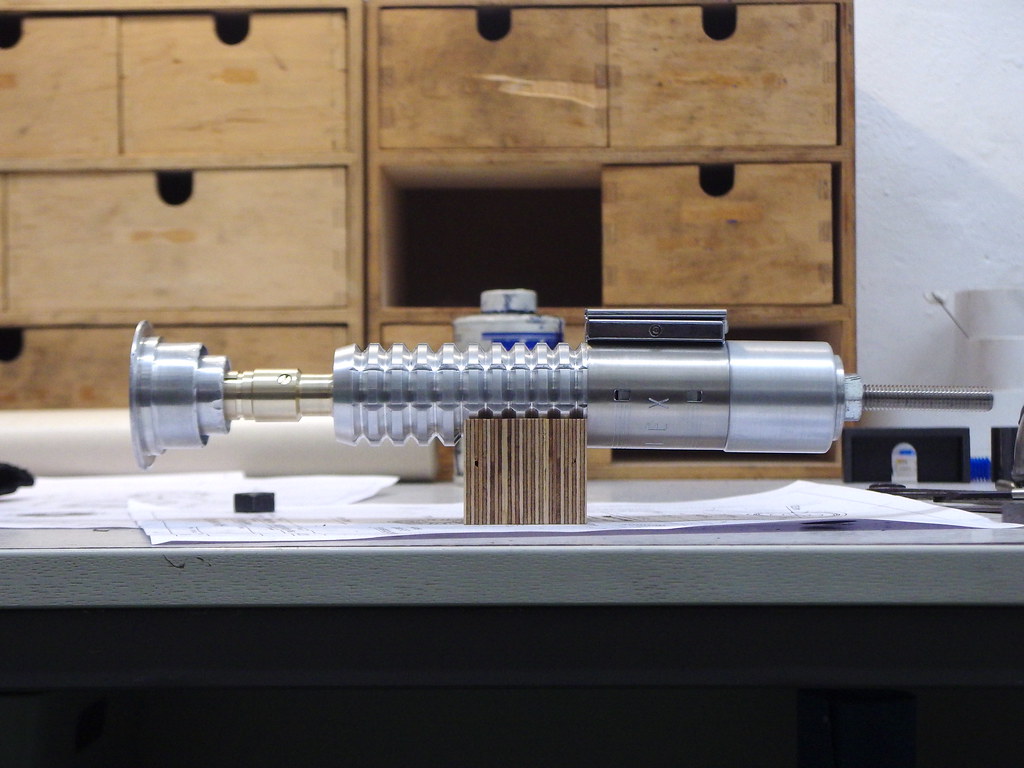

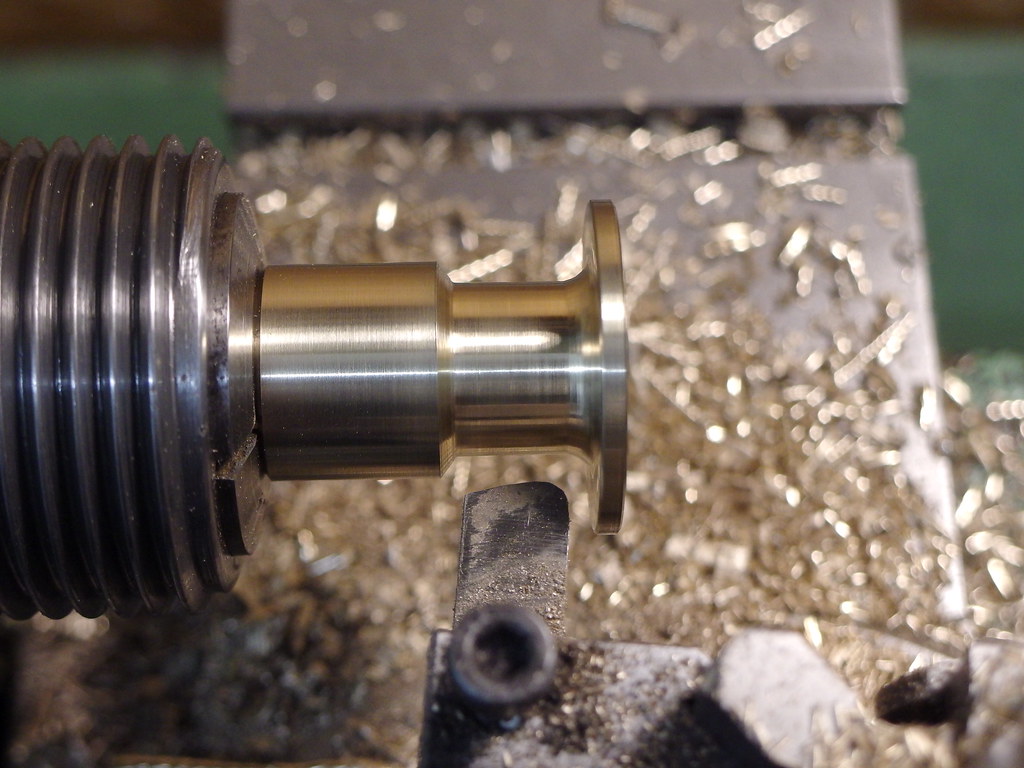

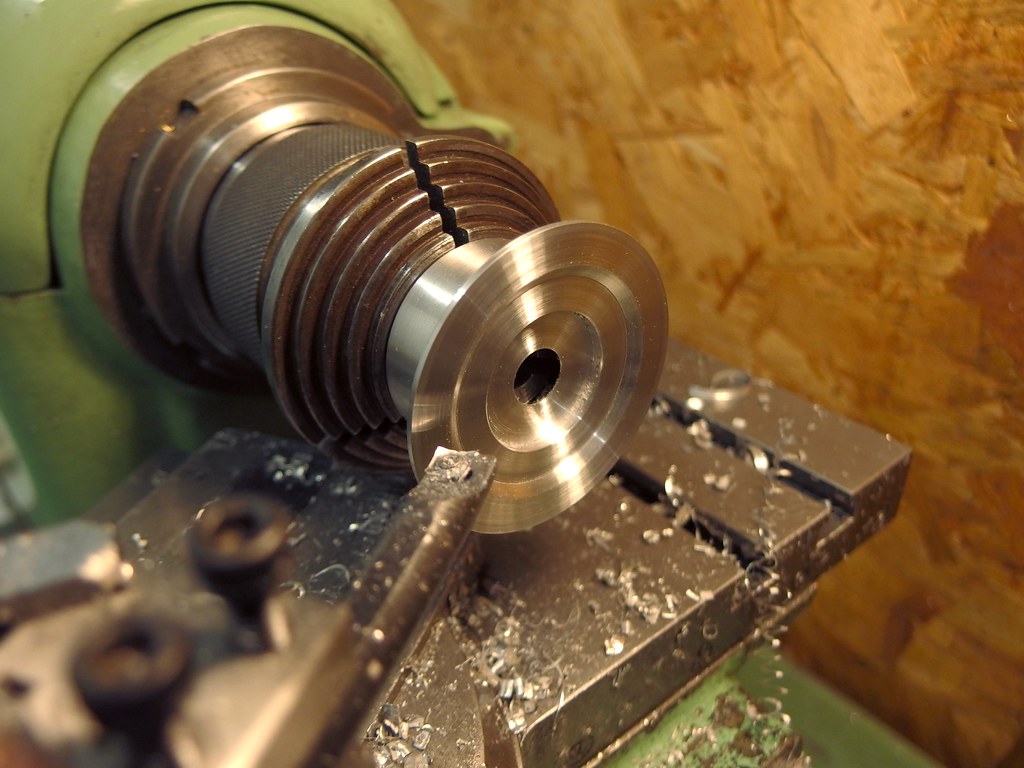

I'd like to share this Obi-Wan saber I've been working on recently. It's all manually machined from aluminium and brass, the Graflex clamp is from The Saber Armory.

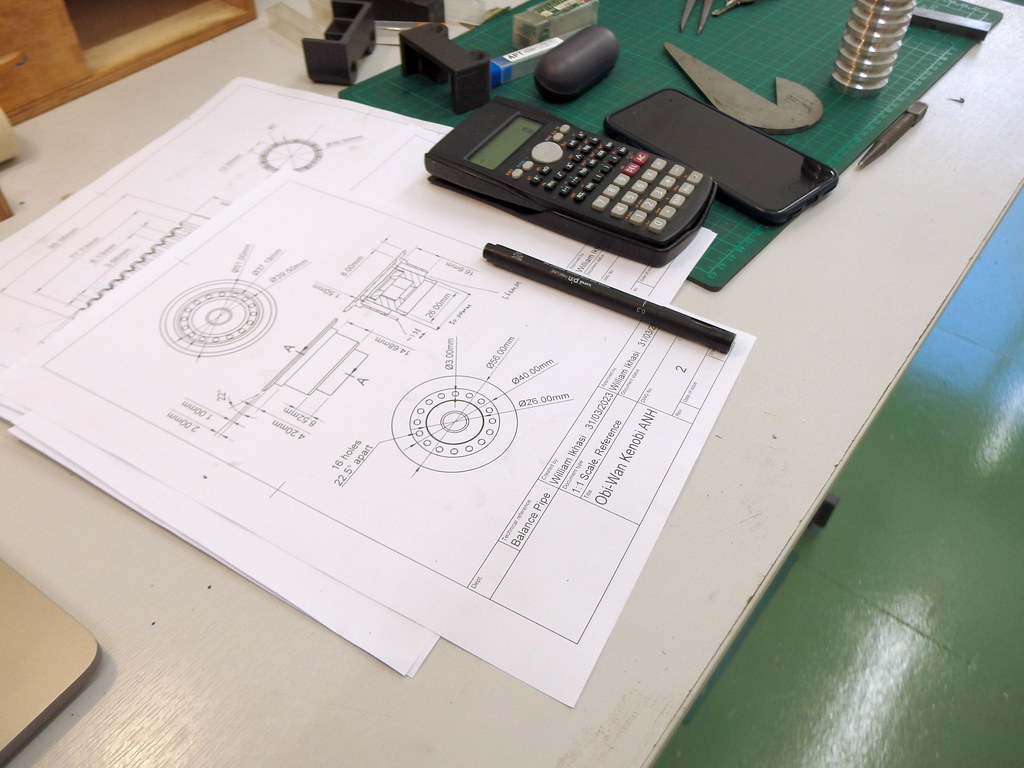

The drawings are taken from my 3D print model which I modelled up last year based on a lot of research and measurements from real parts. Although I would love the real patina and feel of steel components, I was put off by the weight and my machines are better suited to machining aluminium; so I'm going to get the emitter, grenade and booster segments black anodised via my day job.

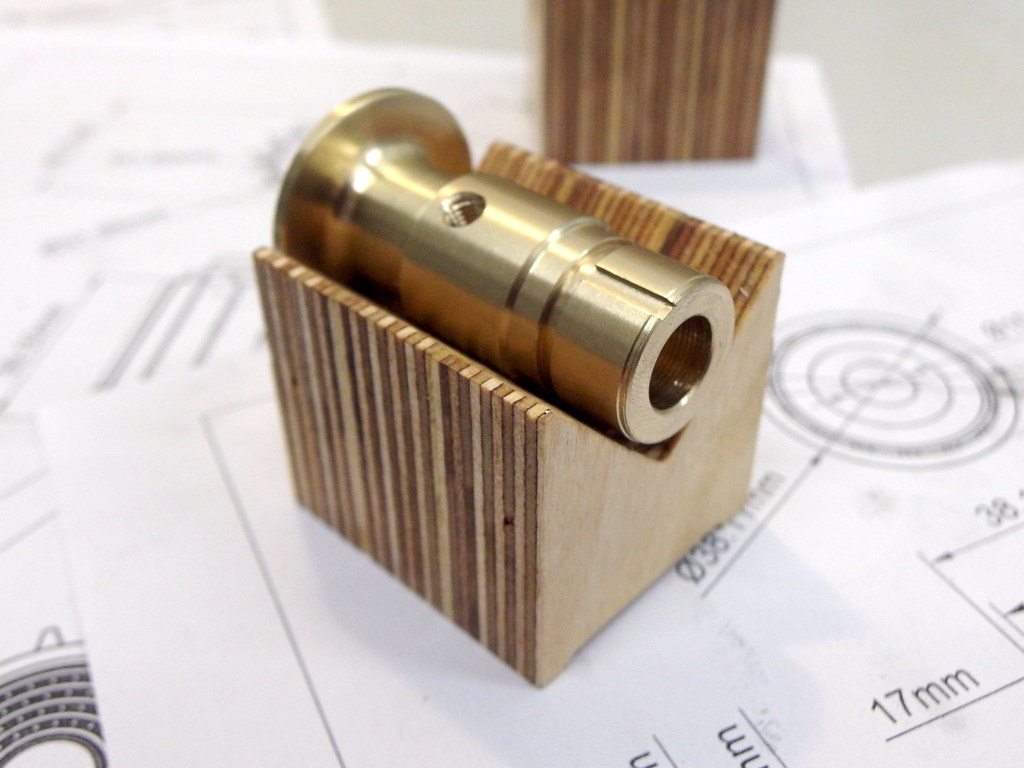

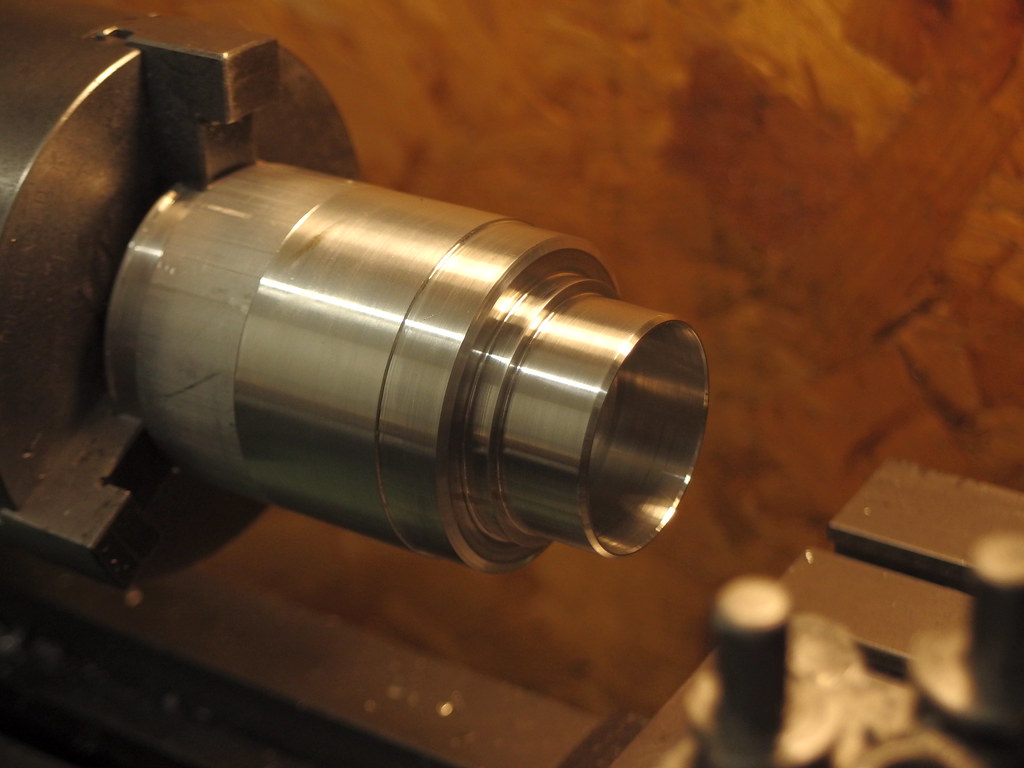

The emitter/balance pipe posed a challenge with that deep trepanned groove. Originally I tried to trepan it but broke tool after tool, so I built it as two press-fit pieces.

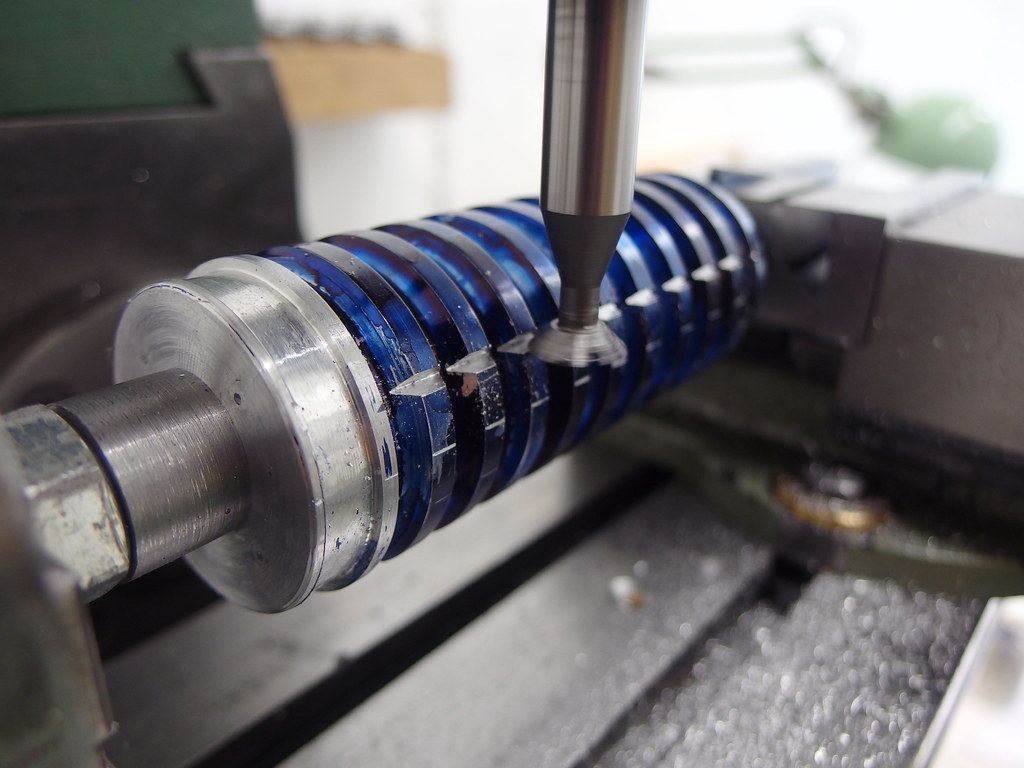

The grenade was more straightforward than I anticipated, I made moderately rigid setup, marked and measured everything 'close enough' and cut the grooves with a 45° dovetail cutter.

The first pass I took too deep and chipped two teeth from the cheapo dovetail cutter, but thankfully it lasted for the other passes.

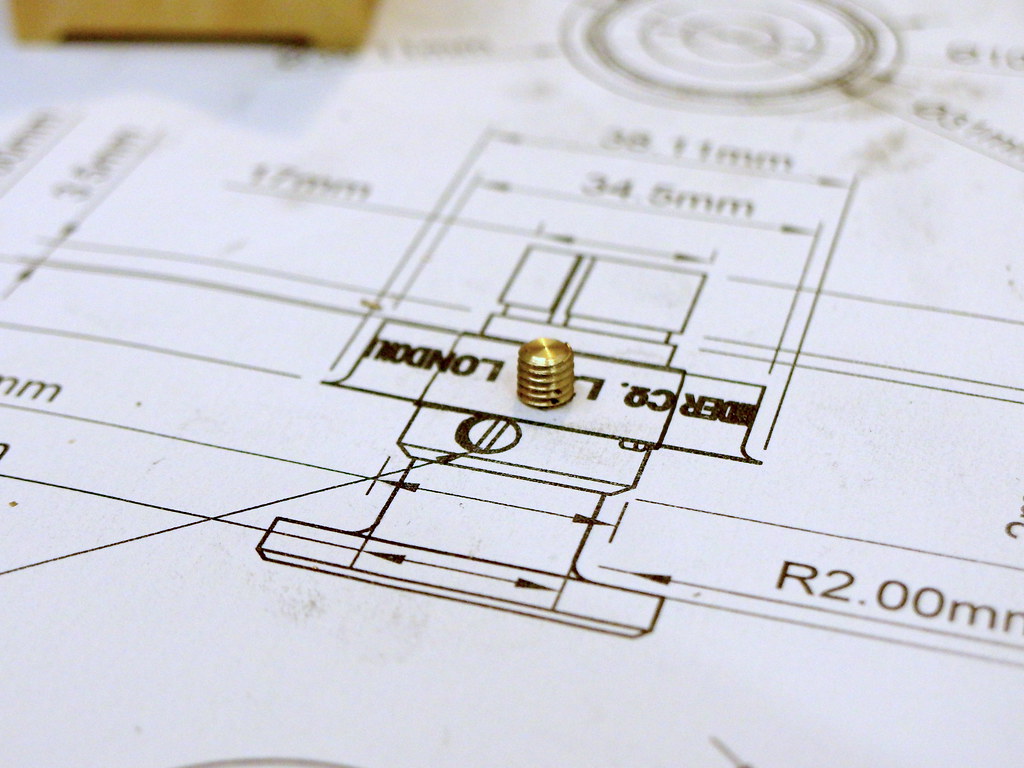

Today I'm going to start cutting slots in the wind vane neck, which will take 16x wind vanes cut from 1mm brass stock.

Thanks for looking, I'll post again later this week!

I've been inactive on here for a long time!

I'd like to share this Obi-Wan saber I've been working on recently. It's all manually machined from aluminium and brass, the Graflex clamp is from The Saber Armory.

The drawings are taken from my 3D print model which I modelled up last year based on a lot of research and measurements from real parts. Although I would love the real patina and feel of steel components, I was put off by the weight and my machines are better suited to machining aluminium; so I'm going to get the emitter, grenade and booster segments black anodised via my day job.

The emitter/balance pipe posed a challenge with that deep trepanned groove. Originally I tried to trepan it but broke tool after tool, so I built it as two press-fit pieces.

The grenade was more straightforward than I anticipated, I made moderately rigid setup, marked and measured everything 'close enough' and cut the grooves with a 45° dovetail cutter.

The first pass I took too deep and chipped two teeth from the cheapo dovetail cutter, but thankfully it lasted for the other passes.

Today I'm going to start cutting slots in the wind vane neck, which will take 16x wind vanes cut from 1mm brass stock.

Thanks for looking, I'll post again later this week!