So I've had a few hours today to devote to this... And my approach today was to fix something about my design that's been bugging me.

You may have noted from previous posts that I made a wire conduit for passing wires across the crystal chamber. I do like my conduit. It makes me not like the random bits of brass tubing that I have on the other two posts underneath the radiator.

So, as the Slothfurnace Way dictates, we must make custom parts!

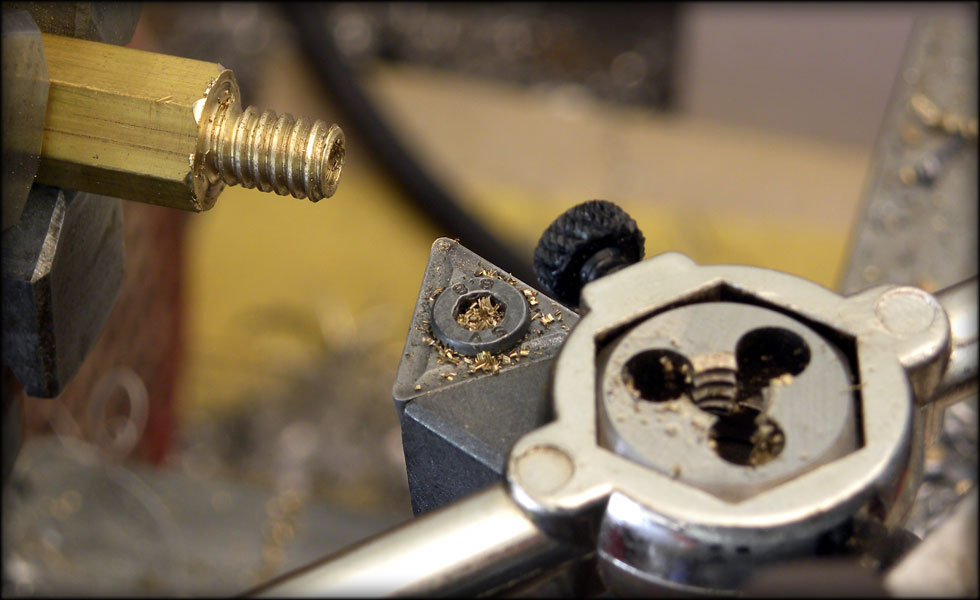

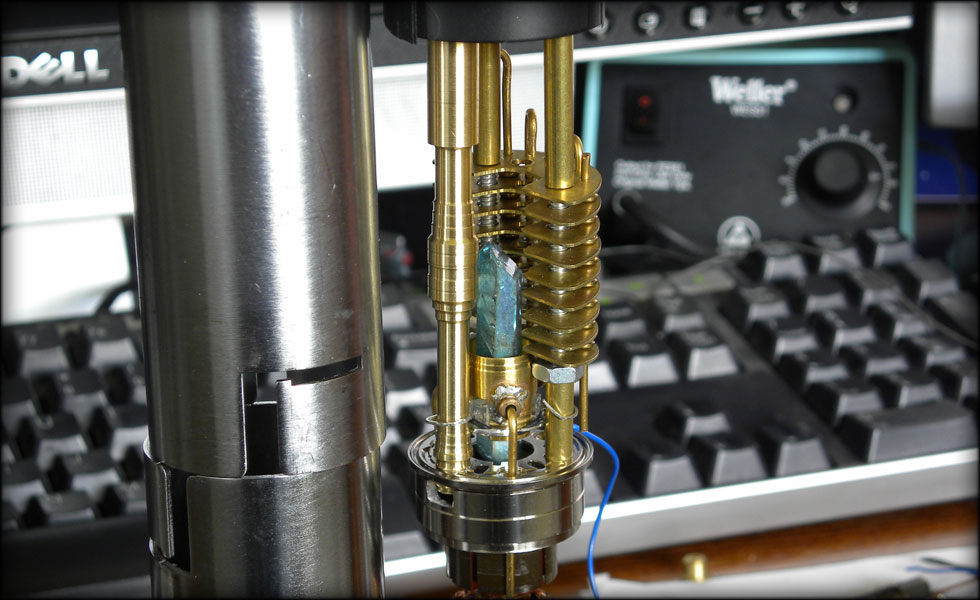

This is a section of brass cut down to match the wire condut base. Notice I have one section, but two pieces. I do this so my diameters match across the two pieces, then I will cut it in the middle and have two matching pieces. It's easier to do this than to start fresh twice.

Here you see the finished pieces that match the conduit. I don't thread these on the outside, but I do thread them 6-32 on the inside to act as nuts so I can tighten the harddrive platter retainer down, and get rid of the 6-32 nut between the brass tubing and radiator as seen in the previous photos.

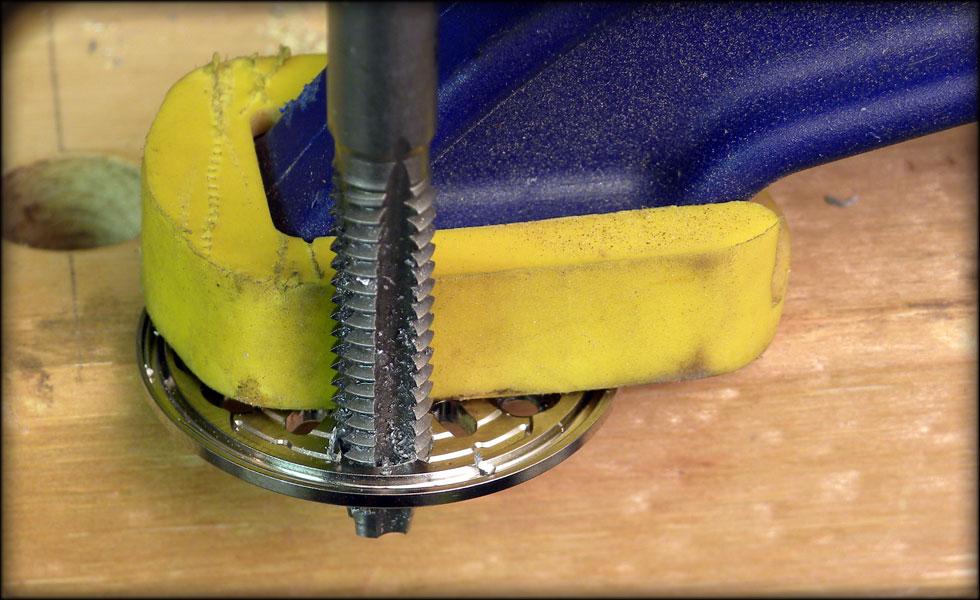

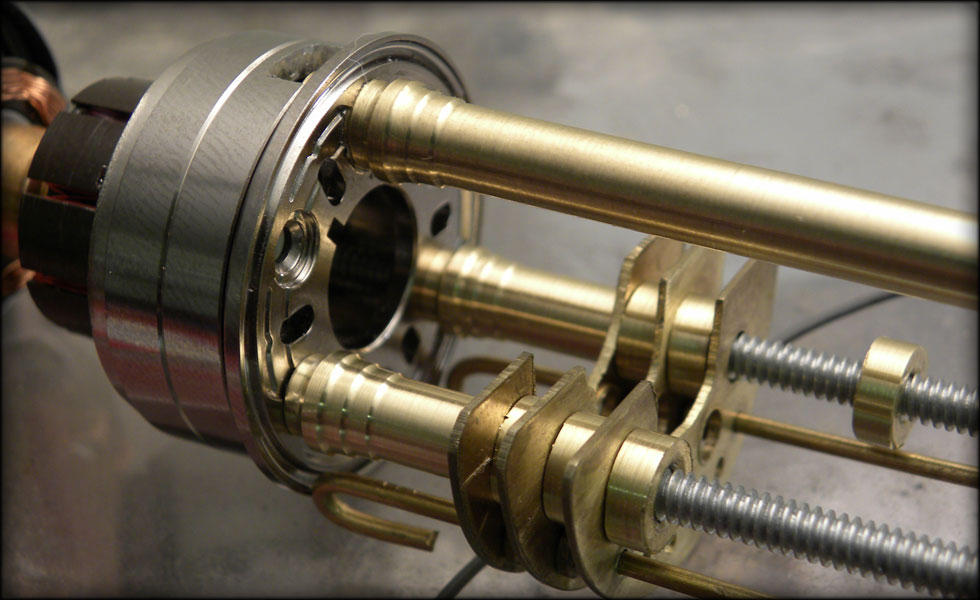

Now I need to turn 16 brass 6-32 nuts down to cylinders. You'll see why in a minute, but it's to further remove unsightly non-custom parts from the chassis.

These are almost the right diameter, don't think I need to shave them down any further.

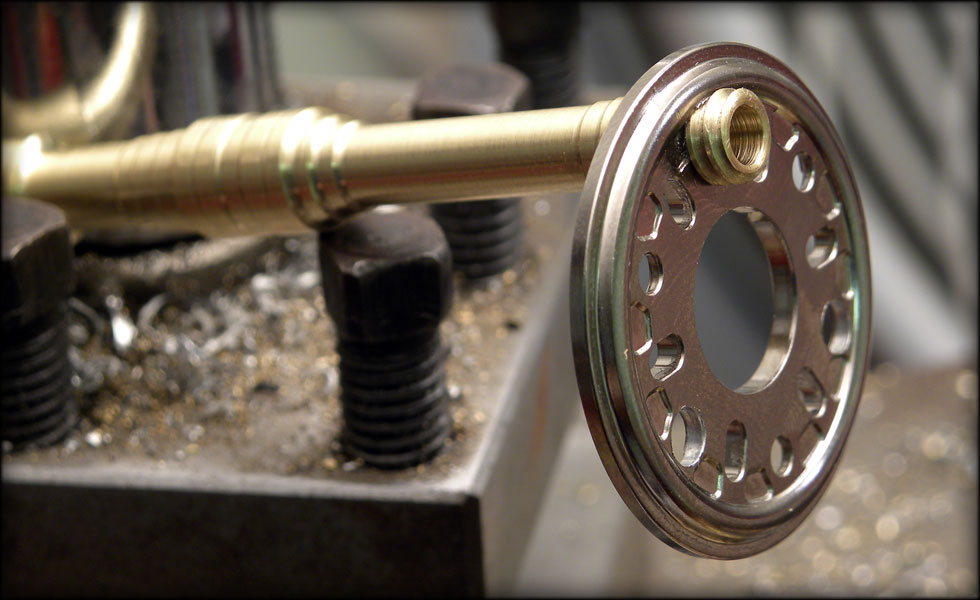

And this is why I need them! I will thread them in between the plates of my radiator. I needed to do this for a couple reasons. Mainly to make more rigid my radiator, as it was a bit floppy when installed because the way it went together meant I couldn't tighten it down. The other reason is, again, to hide the unsightly threaded rod.

MUCH better, I'd say. my three support posts now match aesthetically, and are more functional to tighten things down so nothing moves.

I will polish up a few pieces and re-assemble the radiator. Yes, it will be much more tedious this way, but it's worth it. Also, the with of the brass cylinders is just a hair thinner than the width of the brass guitar string bead ends, so I may leave those out, but I haven't decided.