Good to see this still progressing. What you have looks great.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unused Voyager Tricorder build... Tis FINISHED!<<< Or is it!?

- Thread starter MangyDog

- Start date

ripleys clone

Well-Known Member

Liking the boards. Looks fantastic. This has been one concept piece if wanted to see from paper to actual prop ever since I came across it when I was searching for tricorders. I needed a picture to see a paint scheme fir a mark X build. Just a comparison picture. Saw this concept pop up & was fascinated by it. I had posted this concept at another prop forum, The Reak Prop Zone, years ago & had found lots o interest in it. Even had a few members drawin up schematics & graphics. Then 3D printers came around. I'm eager to see what you have planned & hopefully see it all come together. I'd be very interested in having one for myself. This is a true work of art. You have amazing talent. Far more than I could ever do.

Last edited:

Ok no proper update yet as i had a couple of setbacks with constructing...

I can do with some advise...

i have 2 options. The main button decals and parts around them... Currently the design has 2 sets of decals. One is placed on the recesses that frame the buttons. And ones on the buttons that are recessed in those frames.

I like this layered effect but its proving to be troublesome.

My original plan on how to do these decals is to have the graphics laser printed on frosted dense tracing paper. This so light can pass through the led holes... Backed by white vinyl or white sticky back paper. This giving a white backing for the decals. and holes made for the leds. And all this then laminated with matt finish lamination pouches and stuck to the tricorder.

The first major issue. These lamination pouches i have dome seem to stick amazingly well to the tracing paper i have. In face it doesnt take a huge amount of effect to make them de-laminate.

So when i cut the laminated decals out, and cut the holes for the buttons the pouch material pulls away from the printed tracing paper. This is even with a really fresh sharp scalpel.

So i thought maybe i should apply decals without the lamination and then spray a varnish to seal them... And the tracing paper wrinkled. Ive just spent all morning pealing them off with IPA and damaging the paint work :/

So i need some advice on how to do protect the printed decals and give them a protected finish. Even a better quality lamination? or sticky back cold press thing?

I also want something that could stand the tests of time and not just dry up and peal away like sellotape.

Alternatively. I could change the design and not have recessed button so its flat like the Mark IX/X tricorders and all be one solid decal.

personally i really prefer the recessed button look.

The lamination can survive the cutting for the whole decal. Its just the button cutouts it cant survive.

So what should I do?

Does anyone have any better options for protecting the printed decals?

Or should I just make them simpler and make it all flat?

Please let me know.

I can do with some advise...

i have 2 options. The main button decals and parts around them... Currently the design has 2 sets of decals. One is placed on the recesses that frame the buttons. And ones on the buttons that are recessed in those frames.

I like this layered effect but its proving to be troublesome.

My original plan on how to do these decals is to have the graphics laser printed on frosted dense tracing paper. This so light can pass through the led holes... Backed by white vinyl or white sticky back paper. This giving a white backing for the decals. and holes made for the leds. And all this then laminated with matt finish lamination pouches and stuck to the tricorder.

The first major issue. These lamination pouches i have dome seem to stick amazingly well to the tracing paper i have. In face it doesnt take a huge amount of effect to make them de-laminate.

So when i cut the laminated decals out, and cut the holes for the buttons the pouch material pulls away from the printed tracing paper. This is even with a really fresh sharp scalpel.

So i thought maybe i should apply decals without the lamination and then spray a varnish to seal them... And the tracing paper wrinkled. Ive just spent all morning pealing them off with IPA and damaging the paint work :/

So i need some advice on how to do protect the printed decals and give them a protected finish. Even a better quality lamination? or sticky back cold press thing?

I also want something that could stand the tests of time and not just dry up and peal away like sellotape.

Alternatively. I could change the design and not have recessed button so its flat like the Mark IX/X tricorders and all be one solid decal.

personally i really prefer the recessed button look.

The lamination can survive the cutting for the whole decal. Its just the button cutouts it cant survive.

So what should I do?

Does anyone have any better options for protecting the printed decals?

Or should I just make them simpler and make it all flat?

Please let me know.

I really like Papilio's Polyfocus matte laminate sheets. It takes a little practice to get the application down (you simultaneously pull away the backing while pressing the material down with a decal squeegee) but the results can be really nice.

Polyfocus Matte Overlaminate Adhesive Sheets. (info)

Polyfocus Matte Laminate Sheets - Matte Clear - 9.00 in x 12 in - 20 Sheets (webstore)

Some of the original vacuform VI and VII tricorders used Con-Tact brand clear matte shelf liner to protect the paper control graphics. It's a lower tack product but if you burnish it down it will stay well - my experience using it has only been with standard paper labels and paper card, though, so I can't say how it would work on tracing paper. It seems like this may have been re-branded as a window covering but I can't say with 100% certainty that this is the same product. Name seems to have changed from something along the lines of "Con-Tact Brand Clear Matte Transparent Self-Adhesive Vinyl Drawer and Shelf Liner " to "Con-Tact Brand Clear Covering Self-Adhesive Acid Free Semi-Transparent Privacy Film and Contact Paper Liner"

Polyfocus Matte Overlaminate Adhesive Sheets. (info)

Polyfocus Matte Laminate Sheets - Matte Clear - 9.00 in x 12 in - 20 Sheets (webstore)

Some of the original vacuform VI and VII tricorders used Con-Tact brand clear matte shelf liner to protect the paper control graphics. It's a lower tack product but if you burnish it down it will stay well - my experience using it has only been with standard paper labels and paper card, though, so I can't say how it would work on tracing paper. It seems like this may have been re-branded as a window covering but I can't say with 100% certainty that this is the same product. Name seems to have changed from something along the lines of "Con-Tact Brand Clear Matte Transparent Self-Adhesive Vinyl Drawer and Shelf Liner " to "Con-Tact Brand Clear Covering Self-Adhesive Acid Free Semi-Transparent Privacy Film and Contact Paper Liner"

Yay! Good to know...

Im currently just being held back a bit from showing any real updates by Chinese new year. I've ordered some enameled wire to go through the things and it's taking forever to come... Once i have that I'll run the wires through the hinge and then glue the main faces to the body...

Yesterday the clear vinyl cover arrived. And I've prepped a set of new decals to fit...

I have to day the finish isn't as good as the laminate but the bond is much stronger...

If you look closely theres a slight bubbly distortion. I guess caused by the glue. And the finish is a bit more shine than I'd like... Though still matt. Though it doesn't pull away from tye print when i cut it...

I might throw in a progress pic when I fit the decals... Even if the wire doesn't turn up. Just to keep people happy

Oh one other stupid thing... I may have killed the arduino chip by cooking it with a large blob of solder... Didn't notice as i was mounting the board to the main pcb.

Will do a little testing but will likely have to swap the smd chip out. I got a bunch of the chips in my parts bin...

Oh and I realised a couple of days ago... This projects nearly a year old! No wonder they weren't used on the show ...

...

But in all seriousness i want this prop done... And move onto the next thing...

Im currently just being held back a bit from showing any real updates by Chinese new year. I've ordered some enameled wire to go through the things and it's taking forever to come... Once i have that I'll run the wires through the hinge and then glue the main faces to the body...

Yesterday the clear vinyl cover arrived. And I've prepped a set of new decals to fit...

I have to day the finish isn't as good as the laminate but the bond is much stronger...

If you look closely theres a slight bubbly distortion. I guess caused by the glue. And the finish is a bit more shine than I'd like... Though still matt. Though it doesn't pull away from tye print when i cut it...

I might throw in a progress pic when I fit the decals... Even if the wire doesn't turn up. Just to keep people happy

Oh one other stupid thing... I may have killed the arduino chip by cooking it with a large blob of solder... Didn't notice as i was mounting the board to the main pcb.

Will do a little testing but will likely have to swap the smd chip out. I got a bunch of the chips in my parts bin...

Oh and I realised a couple of days ago... This projects nearly a year old! No wonder they weren't used on the show

But in all seriousness i want this prop done... And move onto the next thing...

OMG an update  ... With actual pics... well pic...

... With actual pics... well pic...

So ive been fitting the decals and such... And trying to hide many of the sins of the recessed buttons...

I must admit it really would have been neater if they were the same level as the main decal surrounds But yeah i wanted to do recessed buttons...

But yeah i wanted to do recessed buttons...

Anyway........ need that wire so i can do the hinges.

So ive been fitting the decals and such... And trying to hide many of the sins of the recessed buttons...

I must admit it really would have been neater if they were the same level as the main decal surrounds

Anyway........ need that wire so i can do the hinges.

Another little update.... With hopefully a bigger one in a few days...

So I'm having to retouch up the paint in the front sensor housing... Using a brush constantly correcting little things... Main fookup was that I used a water based acrylic varnish to seal the front... And the when cleaning some dust off with a wet cloth the varnish started reacting.......... So has to clean as much of it off as I could... Loads more touch ups to do there...

constantly correcting little things... Main fookup was that I used a water based acrylic varnish to seal the front... And the when cleaning some dust off with a wet cloth the varnish started reacting.......... So has to clean as much of it off as I could... Loads more touch ups to do there...

Fitted panels and filled in bits... But of course now I need to carefully mask the screen and decals to repaint it...

Many would think that I should paint first with it all empty and then fit electronics and front sensor bay... Well simply put I can't. It's a complex construction where if I constructed the case first the screen and bulk of the electronics wouldn't fit...

So yeah.... Awkward...

Masking the grey bits around the back of the side sensor clusters is going to be tricky...

Above the mini screen there's a bump in the decal... I think some double sided sticky tape from the first try was left there and missed removing it...... Such a pain...

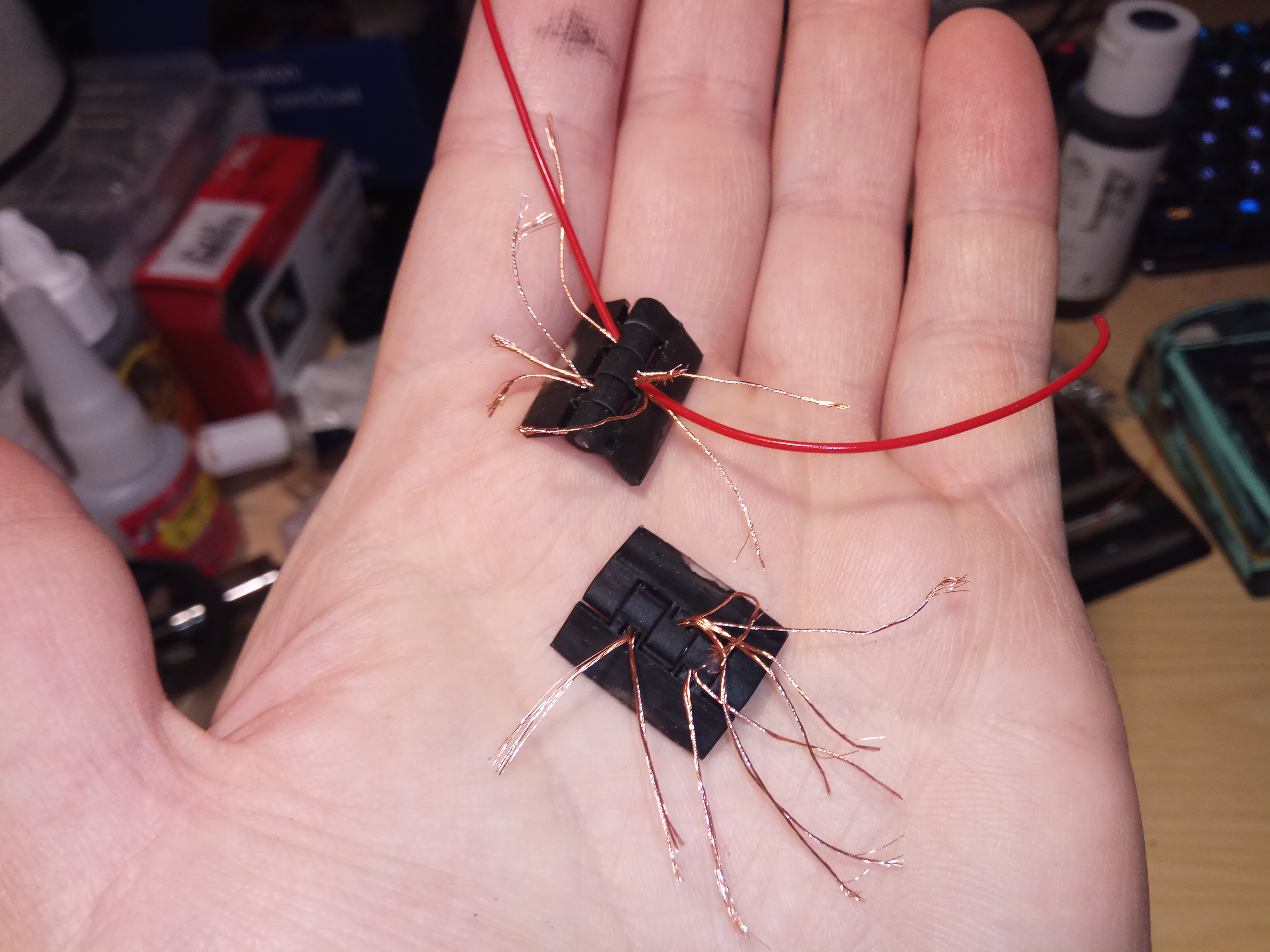

Enameled wire finally turned up and prepped the hinges

I am going to be adding some level of dirt and weathering when the main paint is done... I had always planned this. I have a bit of a back story to this tricorder in the voyager universe... Where unlike the show the everything isnt reset after the episode and everything is clean.... This is going to look like its been used for 7 years....

But of course now this weathering is going to end up masking some of my failings in getting a really great quality paint job done....

So i hope no one minds too much...

So I'm having to retouch up the paint in the front sensor housing... Using a brush

Fitted panels and filled in bits... But of course now I need to carefully mask the screen and decals to repaint it...

Many would think that I should paint first with it all empty and then fit electronics and front sensor bay... Well simply put I can't. It's a complex construction where if I constructed the case first the screen and bulk of the electronics wouldn't fit...

So yeah.... Awkward...

Masking the grey bits around the back of the side sensor clusters is going to be tricky...

Above the mini screen there's a bump in the decal... I think some double sided sticky tape from the first try was left there and missed removing it...... Such a pain...

Enameled wire finally turned up and prepped the hinges

I am going to be adding some level of dirt and weathering when the main paint is done... I had always planned this. I have a bit of a back story to this tricorder in the voyager universe... Where unlike the show the everything isnt reset after the episode and everything is clean.... This is going to look like its been used for 7 years....

But of course now this weathering is going to end up masking some of my failings in getting a really great quality paint job done....

So i hope no one minds too much...

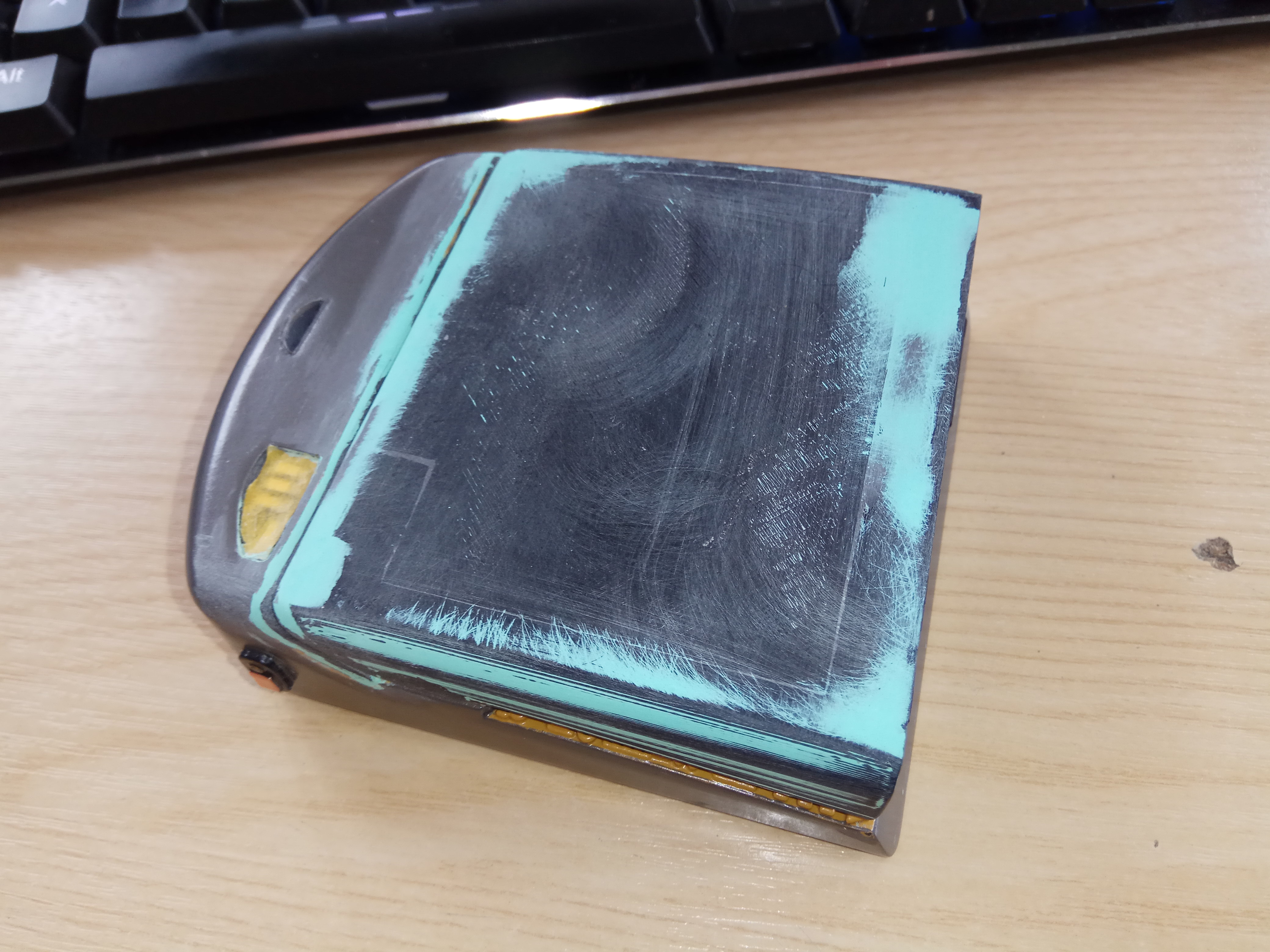

So got the paint on the main body, still got to fit hinges and paint the door

But its getting there.

There really has been a lot of little things thats gone wrong. The photos dont catch them all but I hope its still good enough... Luckily when i add dirt layers and make it seem a little aged, it should mask much of my short comings

Sighs.......

Bad news... So I wired the hinges and got the door stuff working... So powered it up and immediately realised the main fill light on the gel pack has stopped working.

Pressing against it makes it light up so some how the power lead has come off other solder pad during the closing of the case.... I'm weighting up my options of how best to repair it... Right now the least bad option is taking the top decal off making a hole next to the gel pack and carefully solder a new power wire direct to the led.

So effing annoyed with this....

Bad news... So I wired the hinges and got the door stuff working... So powered it up and immediately realised the main fill light on the gel pack has stopped working.

Pressing against it makes it light up so some how the power lead has come off other solder pad during the closing of the case.... I'm weighting up my options of how best to repair it... Right now the least bad option is taking the top decal off making a hole next to the gel pack and carefully solder a new power wire direct to the led.

So effing annoyed with this....

they can but in this case there really shouldnt be an issue... just some how the wires come off the solder pad, Im sure it was a good joint....

And it seems the only way thats certain to fix it would be to cut this panel out so i can get behind it fix the dodgy solder joint and reglue it back, fill it again sand the area off... prime, paint lacquer..... *cries*

And it seems the only way thats certain to fix it would be to cut this panel out so i can get behind it fix the dodgy solder joint and reglue it back, fill it again sand the area off... prime, paint lacquer..... *cries*

Right I had to do it... I couldnt not have it fixed... I carefully cut away with a scalpel so i could pull the face off. And fixed the soldered joint...

What was strange is that the solder looked fine. And power was indeed getting to the other leds on that board. I think what happened a a hairline fracture formed where the line forked to power that 1 led next to the solder point. So i scraped some of the solder mask away and soldered over the trace to reinforce it. hopefully should be fine now.

Yet again, not the post i wanted to make... I really was holding back for a little while here... Wanting to put on a post of a nearly finished (bar software) build of my tricorder... IE painted, pre and then post weathering...

But NOoooooooo poop happens. And im now several steps back......

So first crap bit of news. One thing I really wanted to do was to make the battery removable... As these things dont last forever. It was always the plan to have the battery pull out behind the name tag.

Trouble is after several days trying out different ideas, I simply couldn't come up with a viable solution to putting the battery out and back in without the connecting wires getting tangled or snagged somewhere... So for now at least. The battery is sealed in there.

It can however be pulled out in case of emergency, and if I have a sudden amazing idea. This gives the the opportunity to solve it without having to cut the door out... However I might still end up having to do that some time down the line.

The face glued back and filled....

The plan was to sand back the already painted parts around it, and air brush it back in, and hope it all blended....

Priming and filling, priming and sanding..........

And sanding, and priming and sanding and priming........ Damn this took forever to get this smooth. The texture of the print lines kept coming back through... But in the end i managed it...

You can see the step left by the filler primer.... I planned to sand this back to make it smooth then air brush it again and blend it back to the original paint, However i didnt sand back the lacquer enough

After sanding... thinking it will turn out fine....

No... it didnt turn out fine Not only was there a clear layering going on but the faded airbrushing ended up going crazy paving

Not only was there a clear layering going on but the faded airbrushing ended up going crazy paving

So i had no choice but to strip all the paint there back, i managed to save having to do it to the sensor cluster as theres a well enough defined edge i can work too, as well as the main front face... But because of the smooth curves I had to strip all over the top and sides and bottom.... so effing annoying. Really I was soooo close to being done with the main part of the build.

There you can also see much of the electronics squeezed in there....

Ive re-sanded and done some fine filling again in some of the abs parts that reacted slightly with the acetone (melted a tad, nothing serious) and its nearly prepped and ready to respray with primer...

Ill do the first prime, sand it a little again to make sure its as smooth as i can get, one more prime and then paint with my grey mix.... Give it another day and then lacquer it.... Hopefully ill have something to show by the weekend.... Who knows. Maybe it will catch fire first D:

But NOoooooooo poop happens. And im now several steps back......

So first crap bit of news. One thing I really wanted to do was to make the battery removable... As these things dont last forever. It was always the plan to have the battery pull out behind the name tag.

Trouble is after several days trying out different ideas, I simply couldn't come up with a viable solution to putting the battery out and back in without the connecting wires getting tangled or snagged somewhere... So for now at least. The battery is sealed in there.

It can however be pulled out in case of emergency, and if I have a sudden amazing idea. This gives the the opportunity to solve it without having to cut the door out... However I might still end up having to do that some time down the line.

The face glued back and filled....

The plan was to sand back the already painted parts around it, and air brush it back in, and hope it all blended....

Priming and filling, priming and sanding..........

And sanding, and priming and sanding and priming........ Damn this took forever to get this smooth. The texture of the print lines kept coming back through... But in the end i managed it...

You can see the step left by the filler primer.... I planned to sand this back to make it smooth then air brush it again and blend it back to the original paint, However i didnt sand back the lacquer enough

After sanding... thinking it will turn out fine....

No... it didnt turn out fine

So i had no choice but to strip all the paint there back, i managed to save having to do it to the sensor cluster as theres a well enough defined edge i can work too, as well as the main front face... But because of the smooth curves I had to strip all over the top and sides and bottom.... so effing annoying. Really I was soooo close to being done with the main part of the build.

There you can also see much of the electronics squeezed in there....

Ive re-sanded and done some fine filling again in some of the abs parts that reacted slightly with the acetone (melted a tad, nothing serious) and its nearly prepped and ready to respray with primer...

Ill do the first prime, sand it a little again to make sure its as smooth as i can get, one more prime and then paint with my grey mix.... Give it another day and then lacquer it.... Hopefully ill have something to show by the weekend.... Who knows. Maybe it will catch fire first D:

USS Endeav

Sr Member

Great build up! I am a sucker for props with LCD screens!

I swear its like im cursed....!

I was on track to having this finished as soon as tomorrow...

And was starting to lacquer the painwork... and right away i realised something was wrong. Right away the lacqure bloomed.

Whats worse the bloom is also on the sensor cluster too, so now i have no choice but to have to strip that as well... And I can tell you this is unbelievably annoying. Repainting this is near on impossible. At least not without it looked really bodged

Im just going to go and cry in the corner for a bit.

I was on track to having this finished as soon as tomorrow...

And was starting to lacquer the painwork... and right away i realised something was wrong. Right away the lacqure bloomed.

Whats worse the bloom is also on the sensor cluster too, so now i have no choice but to have to strip that as well... And I can tell you this is unbelievably annoying. Repainting this is near on impossible. At least not without it looked really bodged

Im just going to go and cry in the corner for a bit.

Right heres what I'm going to do.

Having slept on it and asking a couple of friends there thoughts....

It might be possible to cut back the bloomed lacquer on the sensor cluster with the buffer pad on the dremel. Maybe some t cut as well...... If I can get the bloomed stuff off that would save my bacon tbh. As that stuff is impossible to repainted it's multiple parts integrated. And while not obvious on camera, there are several different colours going on.

As for the rest of the body... I'll try cutting it first before stripping it... But I'll probably have to repaint it anyway...

Wish me and my sanity luck

...

Having slept on it and asking a couple of friends there thoughts....

It might be possible to cut back the bloomed lacquer on the sensor cluster with the buffer pad on the dremel. Maybe some t cut as well...... If I can get the bloomed stuff off that would save my bacon tbh. As that stuff is impossible to repainted it's multiple parts integrated. And while not obvious on camera, there are several different colours going on.

As for the rest of the body... I'll try cutting it first before stripping it... But I'll probably have to repaint it anyway...

Wish me and my sanity luck

...

Similar threads

- Replies

- 24

- Views

- 2,228