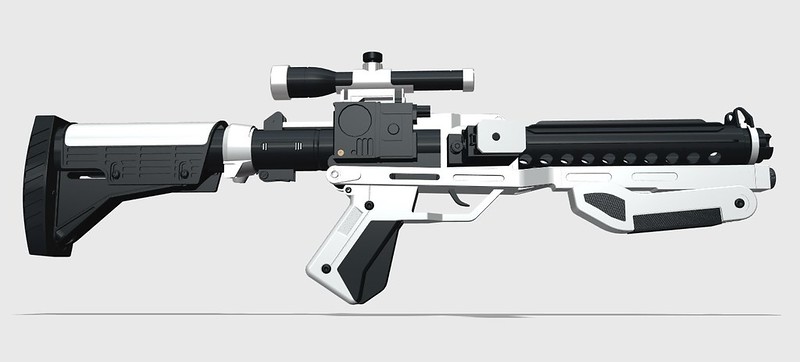

T5H

Active Member

Hello everyone,

I've finished my personal 3D design of the new E-11 blaster from TFA, but i now run into the problem of the printing cost. As i state in my thread's title the final quote from shapeways is over 800$, Sculpteo being even worse regarding this price issue.

So i'm asking people experienced with Shapeways: is there a way to optimize the printing to reduce the cost? The inside diameter of the pipe section is smaller than 40mm so i can't fit anything inside to save some "Machine space", i've already hollowed some parts to save on the "Material cost" and merge others together to save on the "Labor".

Is there a particular way to lay down your parts more efficiently before sending the file to Shapeways? Should i prefer to stack them on upon another, or lay them next to each other, or doesn't it make no differences?

Thanks in advance!

I've finished my personal 3D design of the new E-11 blaster from TFA, but i now run into the problem of the printing cost. As i state in my thread's title the final quote from shapeways is over 800$, Sculpteo being even worse regarding this price issue.

So i'm asking people experienced with Shapeways: is there a way to optimize the printing to reduce the cost? The inside diameter of the pipe section is smaller than 40mm so i can't fit anything inside to save some "Machine space", i've already hollowed some parts to save on the "Material cost" and merge others together to save on the "Labor".

Is there a particular way to lay down your parts more efficiently before sending the file to Shapeways? Should i prefer to stack them on upon another, or lay them next to each other, or doesn't it make no differences?

Thanks in advance!

Attachments

Last edited: