Thank you sir!. She's a labour of love.Stu, this is looking bang on! Your attention to detail is amazing. Great stuff!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building The ANH 5'Millennium Falcon

- Thread starter eagle1

- Start date

Oh, she is a glory to behold... I believe you are at the stage where it's now very hard to make progress, because it's just so satisfying to sit and stare at it for an hour or two in the evenings. I remember this happening to my first Y-Wing: do I keep going and finish? But then I'll have to cover up all this greeblie gorgeousness with paint! Argh! I so badly wanted to "have my cake and eat it too."

Don't get stuck! Push on!!!

Don't get stuck! Push on!!!

Dang Stu!!! AMAZING!!! You continue to make this the finest Falcon build out there!!! Very nice work and very clean!! Looking just right!!!

Thanks for the update!

-Sean

[/QUOTE

Sean, thank you so much. More pics up soon of progress.

Stu,

What is this piece, and/or how did you make/mold/acquire/print your substitute piece:

Thanks,

Read

What is this piece, and/or how did you make/mold/acquire/print your substitute piece:

Thanks,

Read

That detail plate is hand built from many individual styrene shapes to replicate the original. Same process with the 2 other plates on the big landing gear box.Stu,

What is this piece, and/or how did you make/mold/acquire/print your substitute piece:

View attachment 1283643

Thanks,

Read

Fabian 71

Active Member

Hi Stu, I´m following this amazing build. I want to build a Falcon but just at a smaller scale may be a a 32 " could you give some guidance to make the hull using your system, how did you calculate theThought I'd post some progress on my hull dome work.

I realised early on & couldn't find a place in New Zealand anyway to blow mold one piece domes, that really, there is no point to full domes, why wouldn't a half dome or even a quarter dome section work!. So that's what I have done, built an oversize quarter section form or tool, to have the domes vacformed in 4.75mm ABS. The tool is oversized to allow good pulls & trimming when placed on my core. The tool was all CNC'd MDF. Just finishing up the skinning now, which is 3mm MDF. All this will be sanded smooth & filled if needed & sanded again & sealed. Then it will be down to the plastic formers for vacforming. 10 pulls will be needed for 1 Falcon, 8 for the 2 domes,1 for the engine deck & the last for the engine petal strips & maybe another as a spare.

View attachment 840853

View attachment 840854

View attachment 840855

ribs to make the buck? thanks in advance!!

Last edited:

Thank you kind sir!.

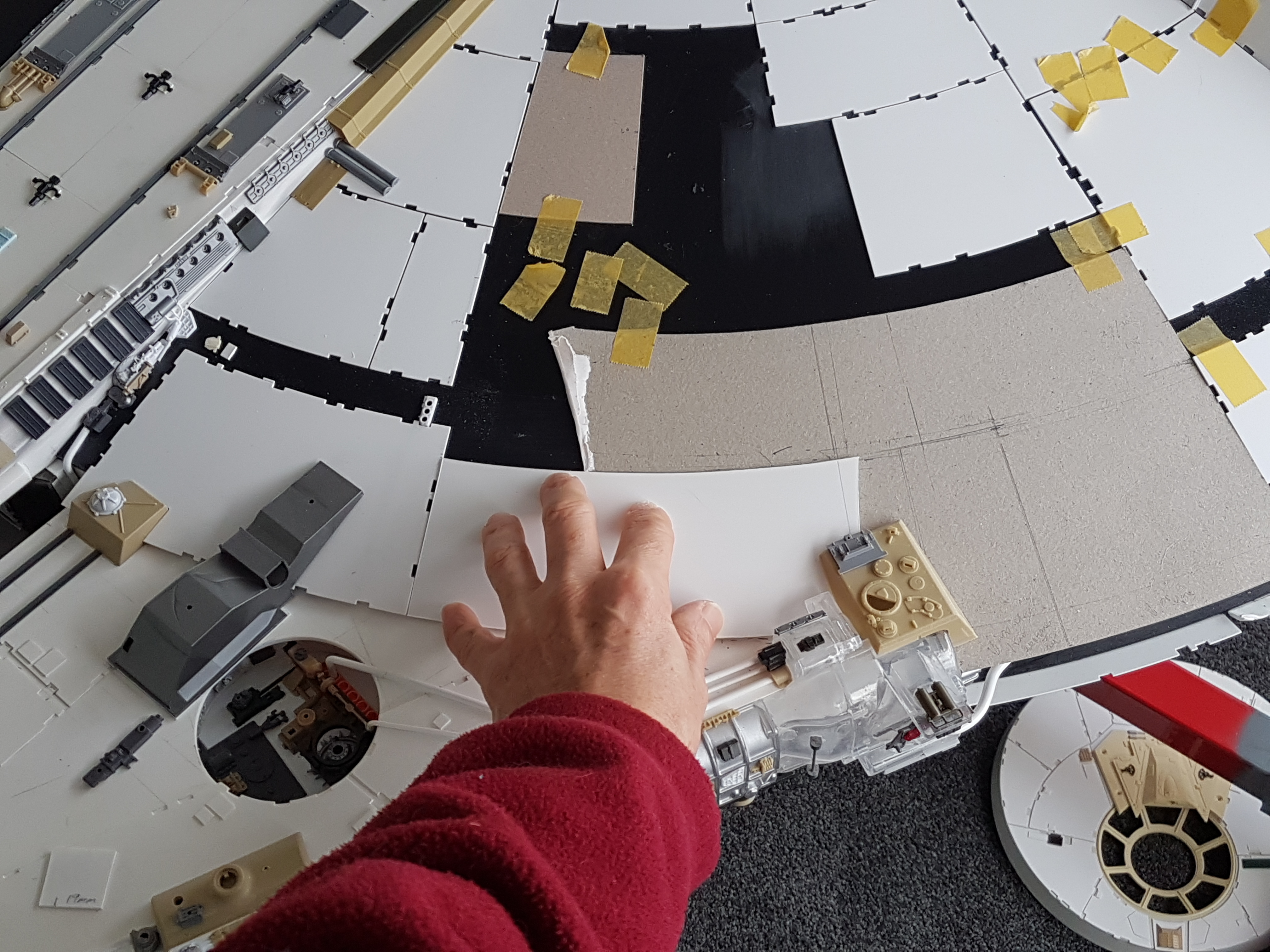

So model is flipped over for the topside plating & 3 pit, one radar pit placement & install.

I find when it comes to plating each section you find out if your subassemblies are slightly off here & there. Not really had any issues at all, oh apart from top of big landing gearbox being a tad too tall on the highest points & was modded to match the ref & all ended up perfect there, but here at the portside mandible top I found where I had marked out the placement of the McLaren tub & where I glued the Panther wedge shaped part were off, the plating overhang to parts not quite fitting to the ref. So popped off the Panther part, brought this forward & pushed the McLaren tub back 3mm. It doesn't seem much, but all these running mods are worth it to match the ref. If you can do it now...then do it!. So really pleased how when these parts are glued down they sit with the plating perfectly.

So model is flipped over for the topside plating & 3 pit, one radar pit placement & install.

I find when it comes to plating each section you find out if your subassemblies are slightly off here & there. Not really had any issues at all, oh apart from top of big landing gearbox being a tad too tall on the highest points & was modded to match the ref & all ended up perfect there, but here at the portside mandible top I found where I had marked out the placement of the McLaren tub & where I glued the Panther wedge shaped part were off, the plating overhang to parts not quite fitting to the ref. So popped off the Panther part, brought this forward & pushed the McLaren tub back 3mm. It doesn't seem much, but all these running mods are worth it to match the ref. If you can do it now...then do it!. So really pleased how when these parts are glued down they sit with the plating perfectly.

Attachments

Thank you Andre.

Well as we know, the proof is in the building & having done the hard yards in blueprinting beforehand.

Minor tweaking & mods while building is nothing new to builds such as this, you only find out by actually putting it all together what works & what doesn't.

Happy to say though that the 'core' is solid & everything is a joy to slap on...a testament to you & Joshua's astonishing blueprinting!.

Well as we know, the proof is in the building & having done the hard yards in blueprinting beforehand.

Minor tweaking & mods while building is nothing new to builds such as this, you only find out by actually putting it all together what works & what doesn't.

Happy to say though that the 'core' is solid & everything is a joy to slap on...a testament to you & Joshua's astonishing blueprinting!.

Topside panel fitout!. Marking out, dry fitting, testing with kit parts, adjusting, templating & final styrene panel placement!.

I think armor panel making & nibbling all the little notches is the best part of the build process, after that...glueing down the kit parts!.

I think armor panel making & nibbling all the little notches is the best part of the build process, after that...glueing down the kit parts!.

Gorgeousness.

blackeagles

New Member

Good morning all,

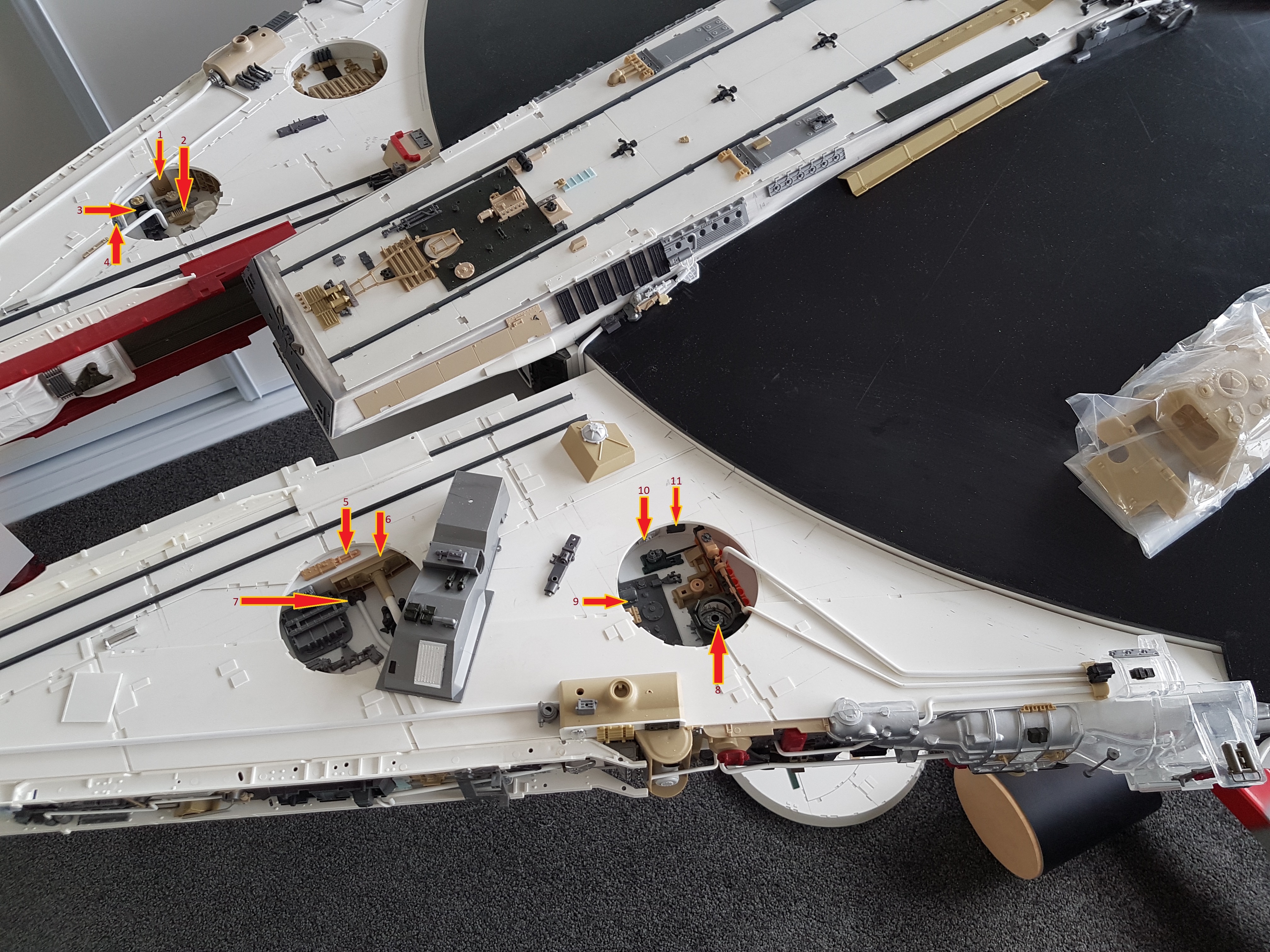

I am contacting you because I have trouble recognizing certain parts: /

I have numbered the ones I have a problem with.

On the other hand, the 9 is tiger I bandai 1/48, and not tamiya? as shown in the kit part?

thank you in advance for your help.

Soon pictures

I am contacting you because I have trouble recognizing certain parts: /

I have numbered the ones I have a problem with.

On the other hand, the 9 is tiger I bandai 1/48, and not tamiya? as shown in the kit part?

thank you in advance for your help.

Soon pictures

blackeagles

New Member

Hi !

You know this kit part please ?

You know this kit part please ?

Similar threads

- Replies

- 9

- Views

- 1,531

- Replies

- 4

- Views

- 1,304

- Replies

- 393

- Views

- 37,219