Ein

Sr Member

Figured I'd get around to doing this!

THE PREFACE:

Here's the deal: I'm looking at making a run available for Guardians of the Galaxy Infinity Orbs. I have done one prototype as a straight 3d print and things worked out well, so now I'm aiming higher. This is what the 3d printed prototype looks like finished:

The Infinity Stone is cast in purple-tinted clear resin. The orbs have 3 purple LEDs controlled by an embedded Arduino Trinket, and run off a 12V N battery. A switch concealed on the orb's exterior allows you to toggle it on and off. The Arduino is programmed to control the LEDs independently of one another, and to fade them in and out at random intervals, which produces a 'stormy' sort of effect when shined into the Infinity Stone, as seen below:

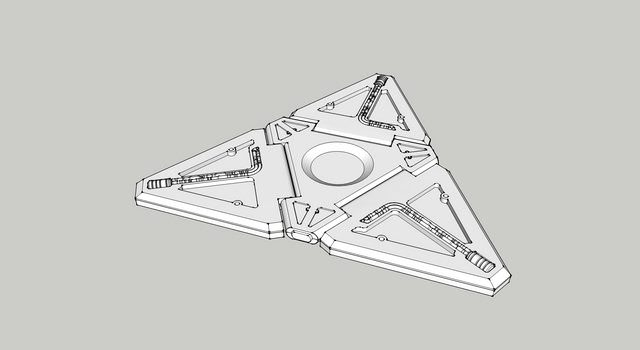

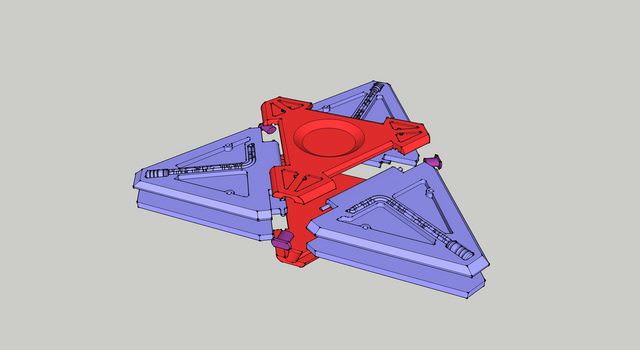

I am also working on an Electromagnet Base to resemble the one seen in the movie to serve as a showpiece.

I am 3d printing a prototype of it right now and trying to play around with scale a little bit until I get it right. It should fold up closed, if that's desired. The idea is just to have something for the orb to sit on to show it off and keep it from rolling off a shelf. To be very clear, I'm calling it an Electromagnet because that's what it seemed to do in the movie - there are no electronics planned for the base itself.

To be very clear, I'm calling it an Electromagnet because that's what it seemed to do in the movie - there are no electronics planned for the base itself.

THE OFFER:

I want to offer completed, finished, lit Infinity Orbs with the accompanying Electromagnet Base. I will be doing the orbs up in cold cast aluminum with an interior done in cold cast bronze. I also plan on doing the bases in cold cast aluminum as well. The orbs will be magnetically latched, like my PLA prototype, meaning I will be using rare earth magnets to hold the two halves together. This provides enough closing force to keep the orbs shut while handling or during cosplay, but a firm pull can still open the orbs up. The infinity gem will be cast in clear resin and magnetized to the inside of the orb to keep it in place - as such, it will be removable if you pull hard enough. It will not light up without the base, since the LEDs are embedded in the orb itself, so please be aware.

These pieces are intended primarily as a showpiece. However, if my 3d printed prototype is any indication, these should be pretty durable and fun props for cosplay purposes, if that's what you're in for. I juggled mine around for the entirety of NYCC 2014 without any issues, and my prototype was simply 3d printed plastic. The final cold cast aluminum copies should be pretty solid and durable. The orbs are also designed to allow for the batteries to be easily changed with a flathead screwdriver. I will mention that after a weekend of pretty repeated use, the orb I have has not begun to even dim yet, so I think the N batteries I'm using are sufficient for the task!

I've done some rough estimates on the cost of materials, electronics, and labor on these, and I've decided the initial batch will be priced at around $299 for the above. This includes shipping to the continental U.S. I am willing to sell and ship internationally, but there will be an additional shipping cost.

I will not be taking payments until the orbs are ready to ship. However, the interest thread will allow me to get a rough feel for how much I need to order in terms of resin, rubber, paint and electronics. I plan on producing the orbs in batches of ten at a time to make my job a little more manageable. I will probably do that until the molds wear out. I will keep an interest list in this OP and as batches of the orbs are completed, I will PM people to get their payment information. If a few days go by without a response, I'll go down the list until that batch is sold, and then start work on a new batch.

THE DISCLAIMERS:

I have worked with resin a ton in the past. I have never worked with cold casting. I don't think it'd be too much harder than what I've done, but I'm pretty sure there will be a bit of a learning curve while I figure out the right proportions for materials. The final product - especially the interior - has a lot of fiddly thin bits that may be difficult to actually cold cast, but I'll have a better idea once I get the molds made.

I have no idea quite when I'll be done producing and shipping these. I plan on doing batches of ten at a time. I'd like to say I'd have them done by the end of November, but it is just a guess, so don't hold me to it. I have to trial and error a couple things, like the casting of the base. This is why I will not be taking any deposits up-front - when they're ready, they're ready. I will be keeping the thread up to date as I go, and expect fairly speedy progress once I iron out the process.

If this whole process goes well, I'll be looking at doing something similar for Star Lord's helmet. Let's find out!

THE LIST:

- JKKS

- bluecoyote

- Jackal

- CaptainEO

- dirtyharriet

- Kevin Gossett

- ahoudini

- Banner

- Westies14

- ajhix

- hazardjsimpson

- Stieller

- 80sKIDAutoman

- cholden

- krell101

- WestBertozzi

- BD Jones

- Darth Clayton

- Effigey

- Nidgit

- Logan Cade

- Azrael69

- MorbidCharlie

- TheStig88

- mikid

- Vitus

- letmebestormy

- MParm

- ZachAbati

- .:MirrorminD:.

- mbmcfarland

- vecna

- Stormshadow

- DBHughes

- doctormckay

- dstengler

- Refjim8

- Jediguy

THE PREFACE:

Here's the deal: I'm looking at making a run available for Guardians of the Galaxy Infinity Orbs. I have done one prototype as a straight 3d print and things worked out well, so now I'm aiming higher. This is what the 3d printed prototype looks like finished:

The Infinity Stone is cast in purple-tinted clear resin. The orbs have 3 purple LEDs controlled by an embedded Arduino Trinket, and run off a 12V N battery. A switch concealed on the orb's exterior allows you to toggle it on and off. The Arduino is programmed to control the LEDs independently of one another, and to fade them in and out at random intervals, which produces a 'stormy' sort of effect when shined into the Infinity Stone, as seen below:

I am also working on an Electromagnet Base to resemble the one seen in the movie to serve as a showpiece.

I am 3d printing a prototype of it right now and trying to play around with scale a little bit until I get it right. It should fold up closed, if that's desired. The idea is just to have something for the orb to sit on to show it off and keep it from rolling off a shelf.

THE OFFER:

I want to offer completed, finished, lit Infinity Orbs with the accompanying Electromagnet Base. I will be doing the orbs up in cold cast aluminum with an interior done in cold cast bronze. I also plan on doing the bases in cold cast aluminum as well. The orbs will be magnetically latched, like my PLA prototype, meaning I will be using rare earth magnets to hold the two halves together. This provides enough closing force to keep the orbs shut while handling or during cosplay, but a firm pull can still open the orbs up. The infinity gem will be cast in clear resin and magnetized to the inside of the orb to keep it in place - as such, it will be removable if you pull hard enough. It will not light up without the base, since the LEDs are embedded in the orb itself, so please be aware.

These pieces are intended primarily as a showpiece. However, if my 3d printed prototype is any indication, these should be pretty durable and fun props for cosplay purposes, if that's what you're in for. I juggled mine around for the entirety of NYCC 2014 without any issues, and my prototype was simply 3d printed plastic. The final cold cast aluminum copies should be pretty solid and durable. The orbs are also designed to allow for the batteries to be easily changed with a flathead screwdriver. I will mention that after a weekend of pretty repeated use, the orb I have has not begun to even dim yet, so I think the N batteries I'm using are sufficient for the task!

I've done some rough estimates on the cost of materials, electronics, and labor on these, and I've decided the initial batch will be priced at around $299 for the above. This includes shipping to the continental U.S. I am willing to sell and ship internationally, but there will be an additional shipping cost.

I will not be taking payments until the orbs are ready to ship. However, the interest thread will allow me to get a rough feel for how much I need to order in terms of resin, rubber, paint and electronics. I plan on producing the orbs in batches of ten at a time to make my job a little more manageable. I will probably do that until the molds wear out. I will keep an interest list in this OP and as batches of the orbs are completed, I will PM people to get their payment information. If a few days go by without a response, I'll go down the list until that batch is sold, and then start work on a new batch.

THE DISCLAIMERS:

I have worked with resin a ton in the past. I have never worked with cold casting. I don't think it'd be too much harder than what I've done, but I'm pretty sure there will be a bit of a learning curve while I figure out the right proportions for materials. The final product - especially the interior - has a lot of fiddly thin bits that may be difficult to actually cold cast, but I'll have a better idea once I get the molds made.

I have no idea quite when I'll be done producing and shipping these. I plan on doing batches of ten at a time. I'd like to say I'd have them done by the end of November, but it is just a guess, so don't hold me to it. I have to trial and error a couple things, like the casting of the base. This is why I will not be taking any deposits up-front - when they're ready, they're ready. I will be keeping the thread up to date as I go, and expect fairly speedy progress once I iron out the process.

If this whole process goes well, I'll be looking at doing something similar for Star Lord's helmet. Let's find out!

THE LIST:

- JKKS

- bluecoyote

- Jackal

- CaptainEO

- dirtyharriet

- Kevin Gossett

- ahoudini

- Banner

- Westies14

- ajhix

- hazardjsimpson

- Stieller

- 80sKIDAutoman

- cholden

- krell101

- WestBertozzi

- BD Jones

- Darth Clayton

- Effigey

- Nidgit

- Logan Cade

- Azrael69

- MorbidCharlie

- TheStig88

- mikid

- Vitus

- letmebestormy

- MParm

- ZachAbati

- .:MirrorminD:.

- mbmcfarland

- vecna

- Stormshadow

- DBHughes

- doctormckay

- dstengler

- Refjim8

- Jediguy

Attachments

-

vUVJGYXl.jpg42 KB · Views: 455

vUVJGYXl.jpg42 KB · Views: 455 -

vUVJGYXl.jpg42 KB · Views: 86

vUVJGYXl.jpg42 KB · Views: 86 -

vUVJGYXl.jpg42 KB · Views: 99

vUVJGYXl.jpg42 KB · Views: 99 -

vUVJGYXl.jpg42 KB · Views: 103

vUVJGYXl.jpg42 KB · Views: 103 -

vUVJGYXl.jpg42 KB · Views: 91

vUVJGYXl.jpg42 KB · Views: 91 -

dxZQ521l.jpg56.1 KB · Views: 433

dxZQ521l.jpg56.1 KB · Views: 433 -

dxZQ521l.jpg56.1 KB · Views: 115

dxZQ521l.jpg56.1 KB · Views: 115 -

dxZQ521l.jpg56.1 KB · Views: 93

dxZQ521l.jpg56.1 KB · Views: 93 -

dxZQ521l.jpg56.1 KB · Views: 89

dxZQ521l.jpg56.1 KB · Views: 89 -

dxZQ521l.jpg56.1 KB · Views: 102

dxZQ521l.jpg56.1 KB · Views: 102 -

CPqDhoOl.jpg17.2 KB · Views: 103

CPqDhoOl.jpg17.2 KB · Views: 103 -

CPqDhoOl.jpg17.2 KB · Views: 95

CPqDhoOl.jpg17.2 KB · Views: 95 -

CPqDhoOl.jpg17.2 KB · Views: 97

CPqDhoOl.jpg17.2 KB · Views: 97 -

CPqDhoOl.jpg17.2 KB · Views: 92

CPqDhoOl.jpg17.2 KB · Views: 92 -

CPqDhoOl.jpg17.2 KB · Views: 97

CPqDhoOl.jpg17.2 KB · Views: 97 -

UBj1lG3l.jpg17.5 KB · Views: 106

UBj1lG3l.jpg17.5 KB · Views: 106 -

UBj1lG3l.jpg17.5 KB · Views: 95

UBj1lG3l.jpg17.5 KB · Views: 95 -

UBj1lG3l.jpg17.5 KB · Views: 94

UBj1lG3l.jpg17.5 KB · Views: 94 -

UBj1lG3l.jpg17.5 KB · Views: 102

UBj1lG3l.jpg17.5 KB · Views: 102 -

UBj1lG3l.jpg17.5 KB · Views: 92

UBj1lG3l.jpg17.5 KB · Views: 92

Last edited by a moderator: