The fuselage is 2" dia. These guys were in California building these models, I doubt most of them used Metric, stupid America. Also, you have to go off of known measurements, like kit parts. I never trust anyone elses measurements or even my own (that's a paraphrase from someone else, I forget who). The cross bar is .75in.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let's Build a TIE Bomber!

- Thread starter Boxcar Bret

- Start date

Boxcar Bret

View attachment 1812518

What outer diamater is it? or what have u chosen, i saw, that in the drawings, in each view, rear, top and inner wing have a diffrent diameter

top view 21,5mm

rear view 19mm

inner wing 20mm

Mine is 20.7mm

i think i found my root of the problems

View attachment 1812834the red area witch is not seen in the front or rear view, is inside the thick part, maybe i should have made it green

but u can already see, that not all views are to scale to each other

all views have a main fuselage of 52mm, except the bottom view, wich is smaller, only 51mm

View attachment 1812840

long story short, watch out your measurements

i have chosen now 21,5mm for the "x"

and Boxcar Bret, witch measurment did u take for the fuselage now, did u find an abs tube of 2 inches(50,8mm)?

will you work with 51mm or 52mm?

witch of both is actualy correct?

I used 2" ABS Gray Tube from Plastruct (TB-200)

Like SWgeek said, don't trust other's measurements, even your own. In my short time doing scratch builds I've learned to trust but verify. Look at your reference and use known measurements of parts. I will use plans, photos, collective research from the RPF and after all that it comes down to averaging all the information into a calculated guess and rolling the dice. Sometimes it works and sometimes you end up hitting people for parts.

rbeach84

Sr Member

Also, make sure that all prints are to the same 'scale' in both X and Y directions, using the included rulers (there just for that purpose). Some printing/repro/scanning results may introduce some distortion (a well-known (?) issue with some copiers due to a parallax error.)

Cheers! Robert

Cheers! Robert

Rulebreaker

New Member

Boxcar Bret

can u make detail picture of the shinano part, i think the retooling kit 31215 doent have them, only the original 77024

Maybe the "rocket launchers" part D14 of 31215

of 31215

can u make detail picture of the shinano part, i think the retooling kit 31215 doent have them, only the original 77024

Maybe the "rocket launchers" part D14

May 5, 2024

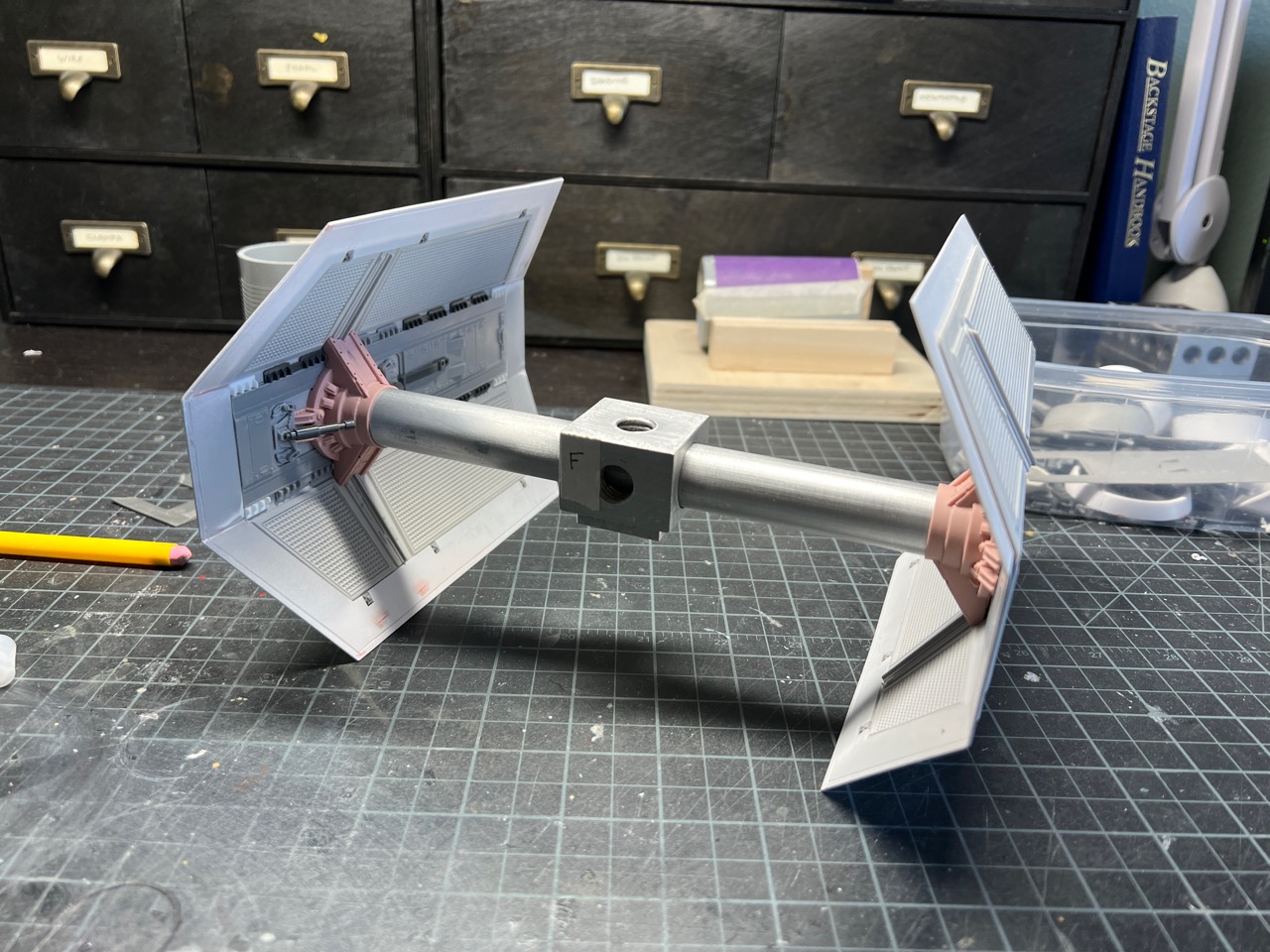

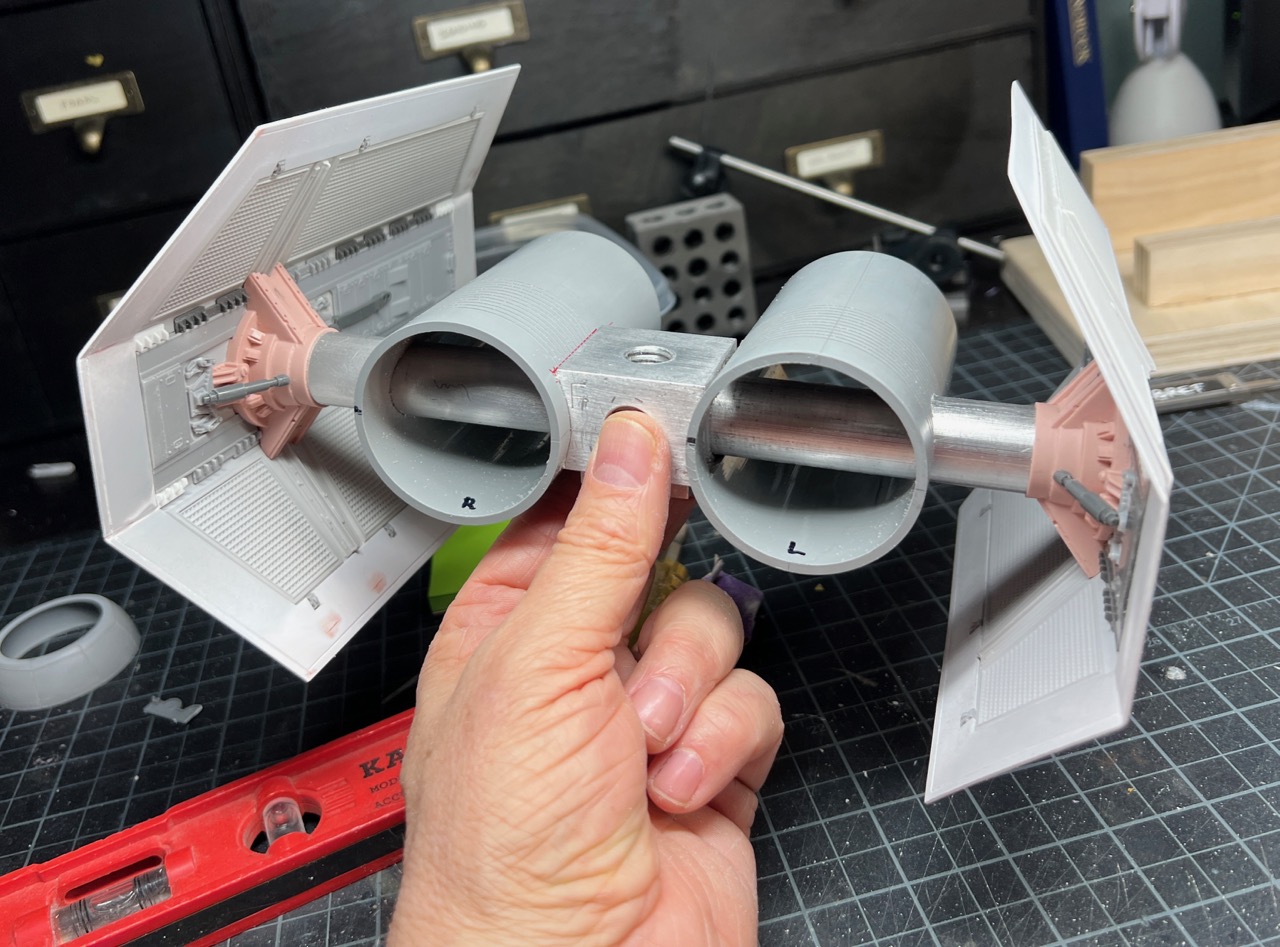

Work that body! Work that body! With the wings in a reasonable state of completion it was starting to look like a Star War.

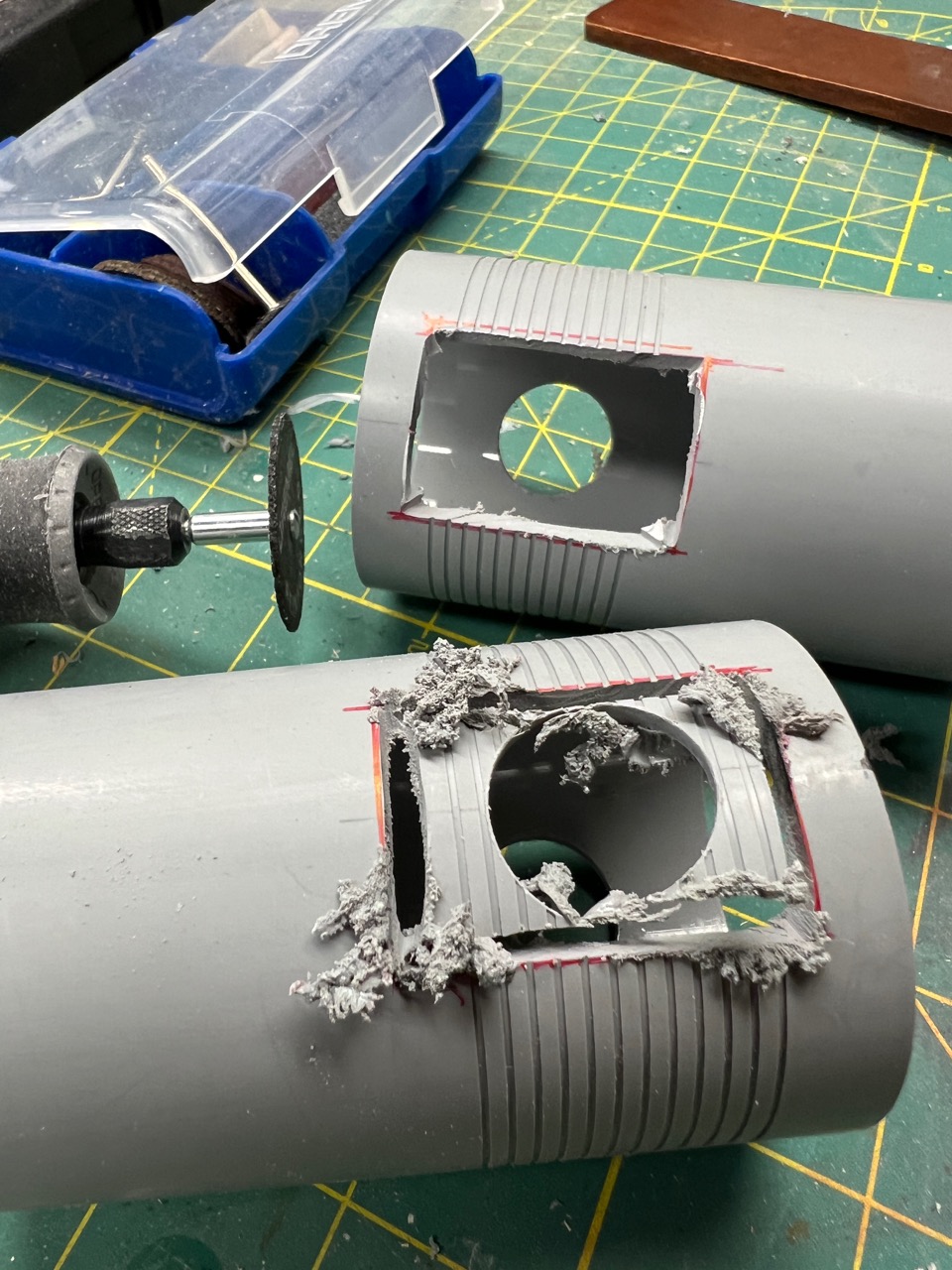

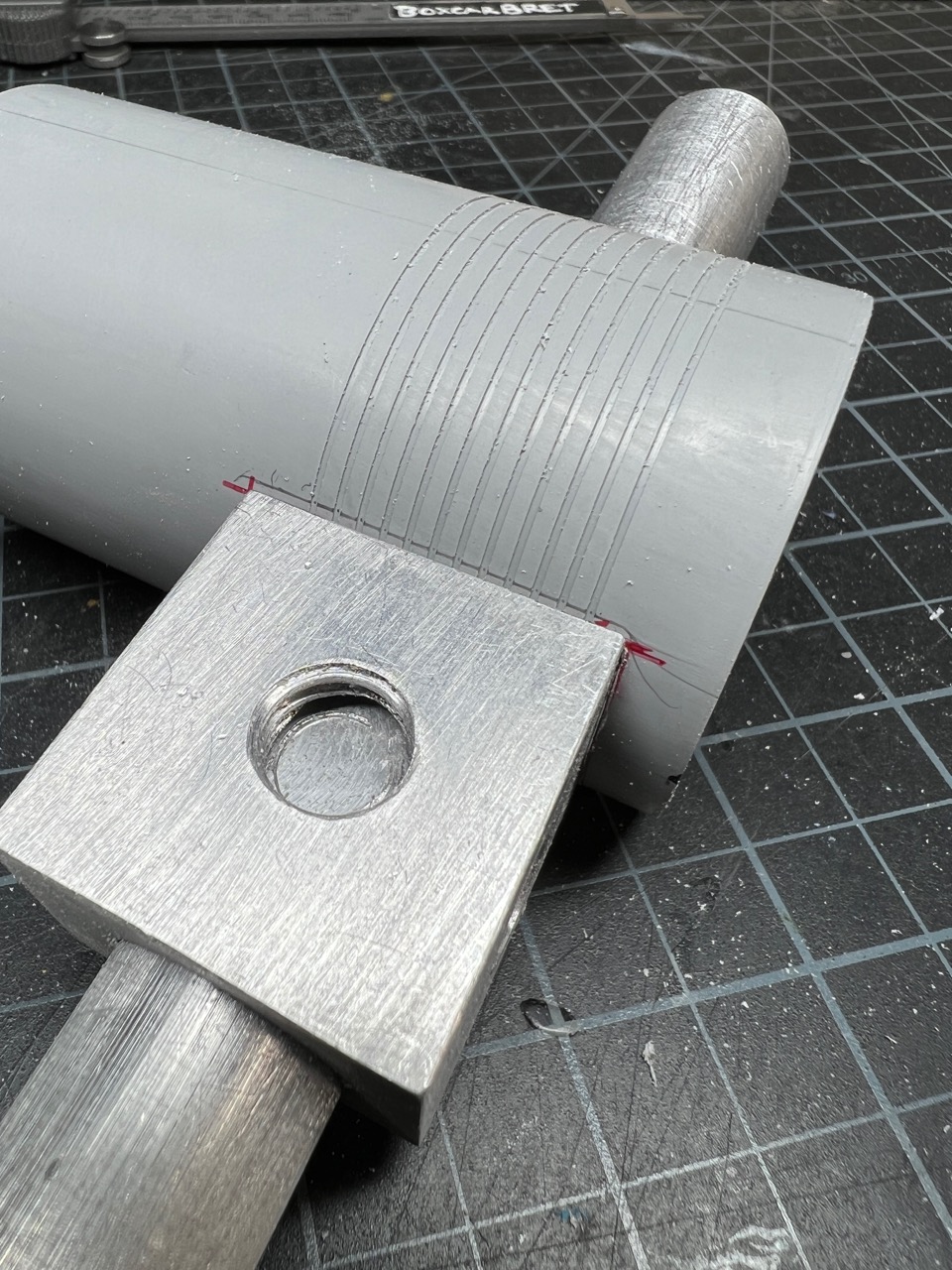

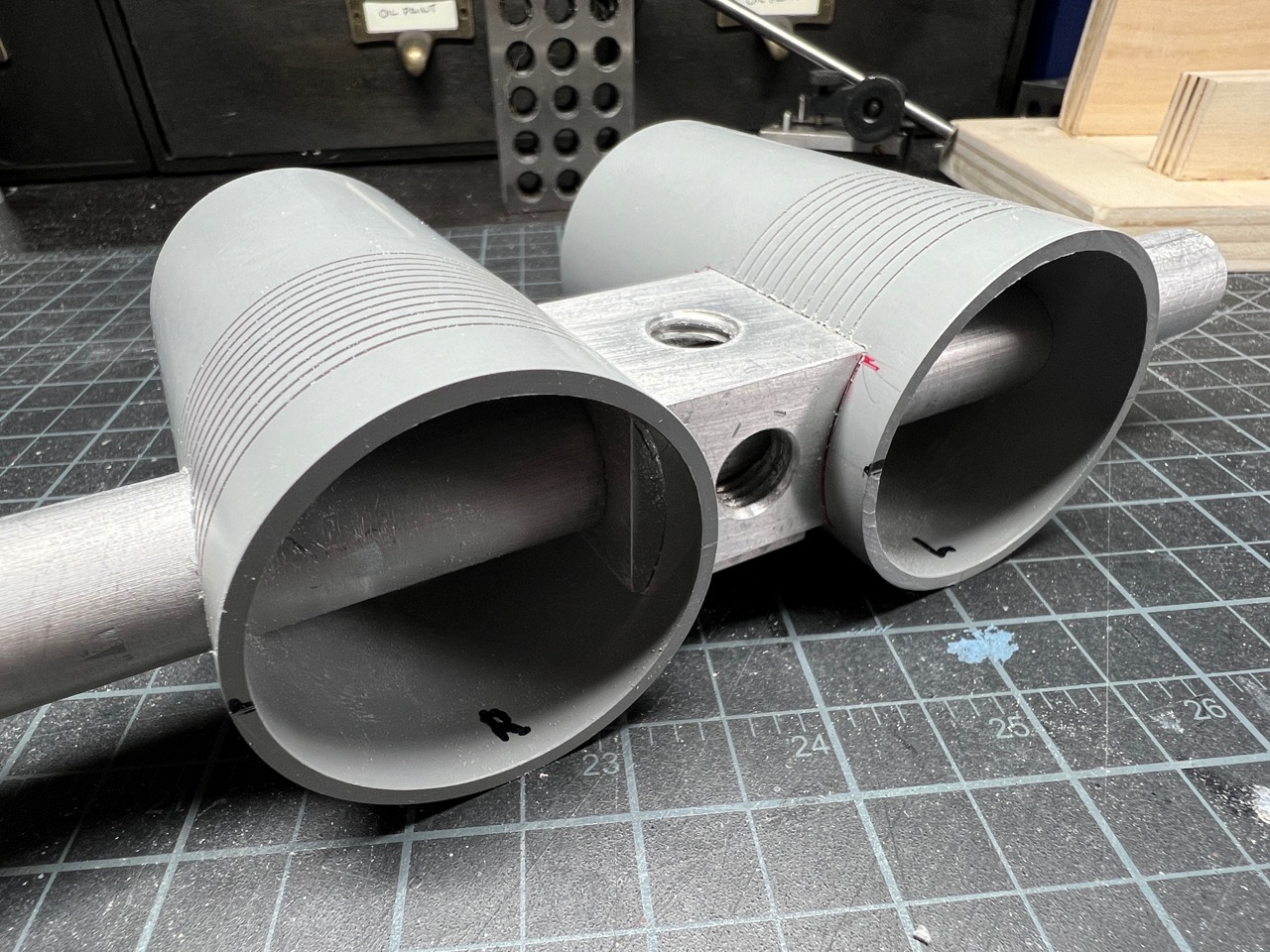

It was time to measure out and cut the openings in the body tubes for the armature.

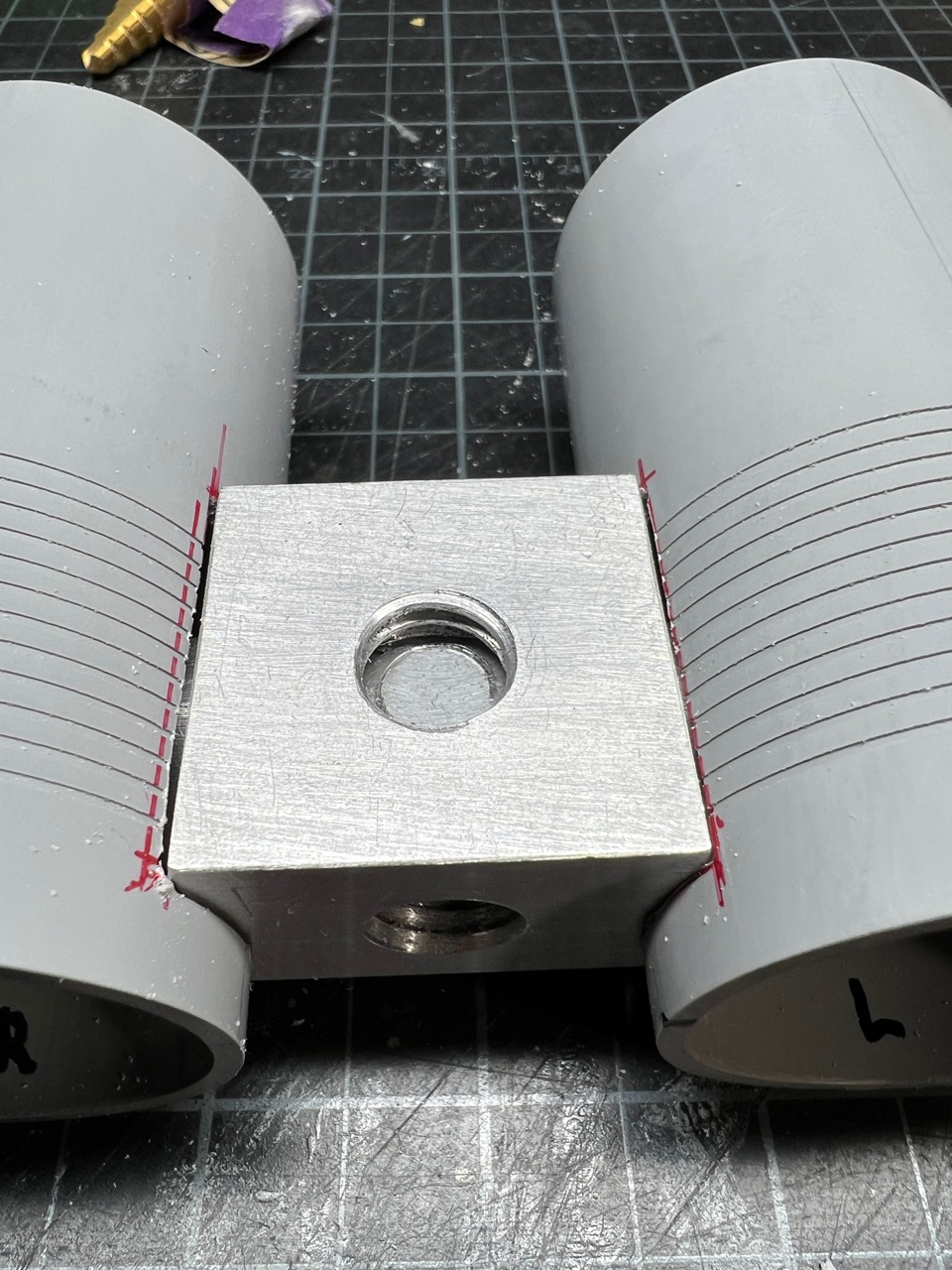

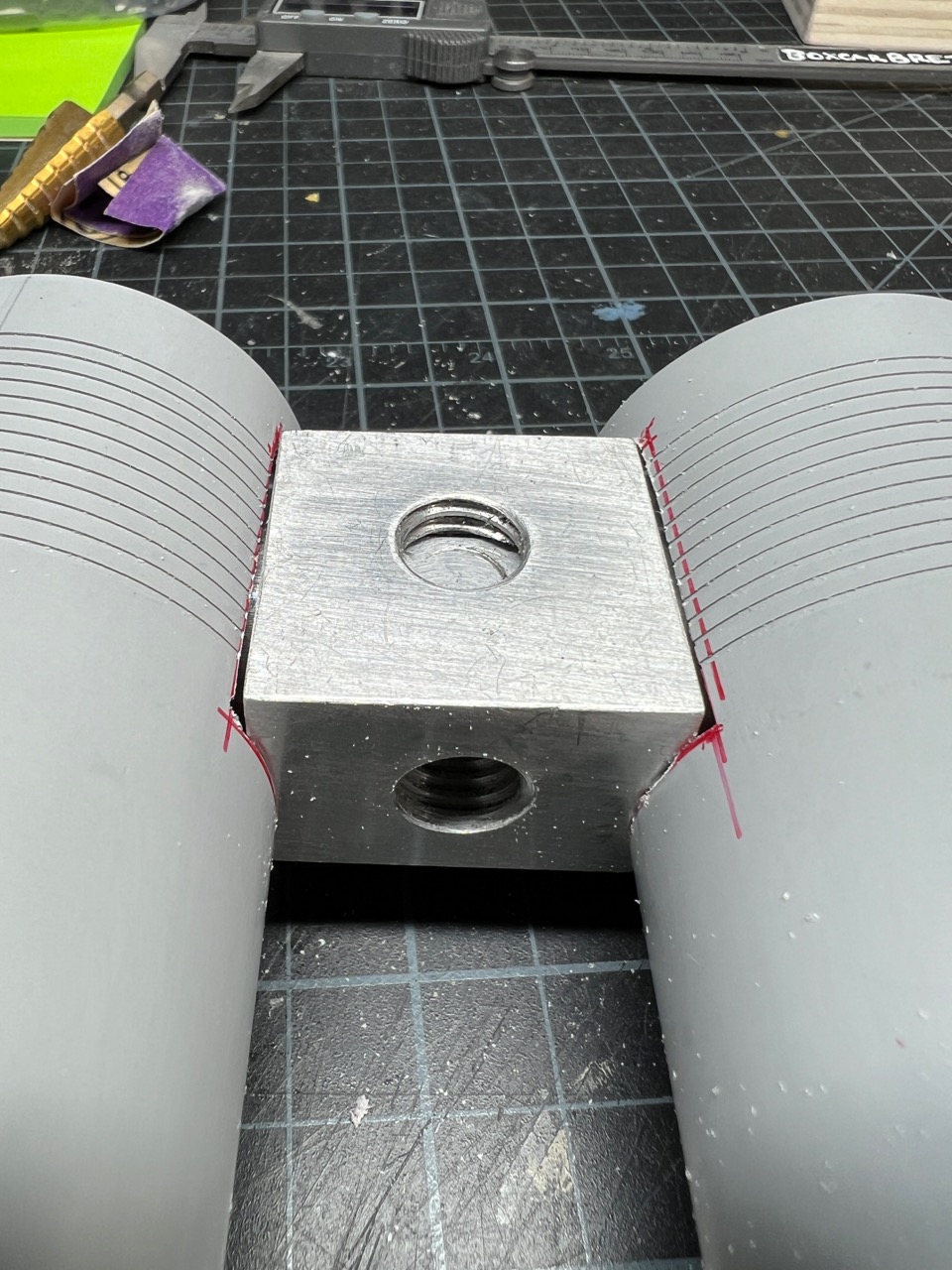

The plan was to drill the holes for the round pipe to pass through both sides and then open up the inward facing sides to accommodate the mounting block. I started by finding the center and marking it with scribe.

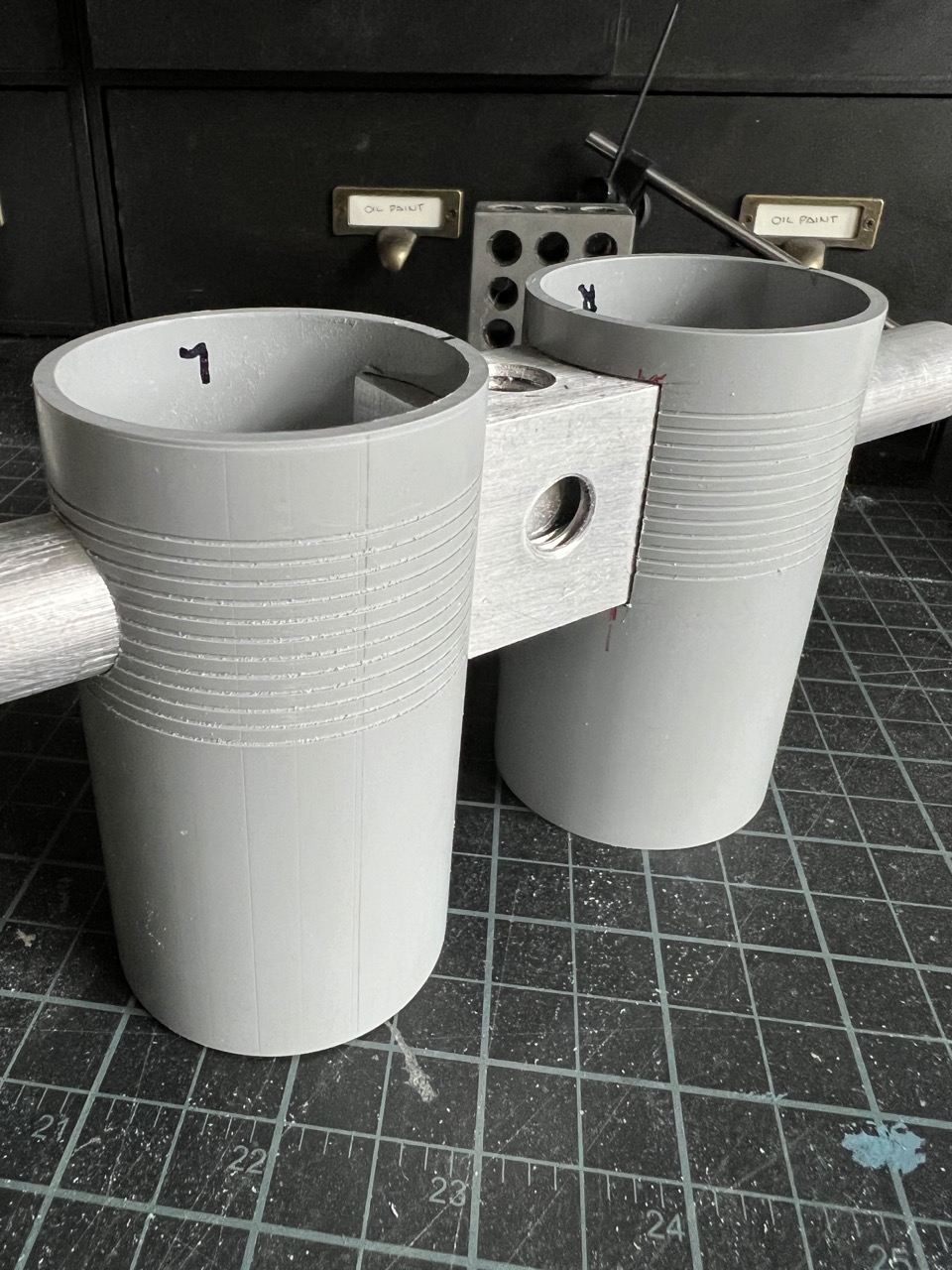

I then took it to the drill press to drill a 1/8" pilot hole.

Once the pilot hole was drilled I switched to a step bit to open up the hole. My step bits are from Horror Freight so they're not quite .75" but actually worked in my favor because it made for a nice snug fit.

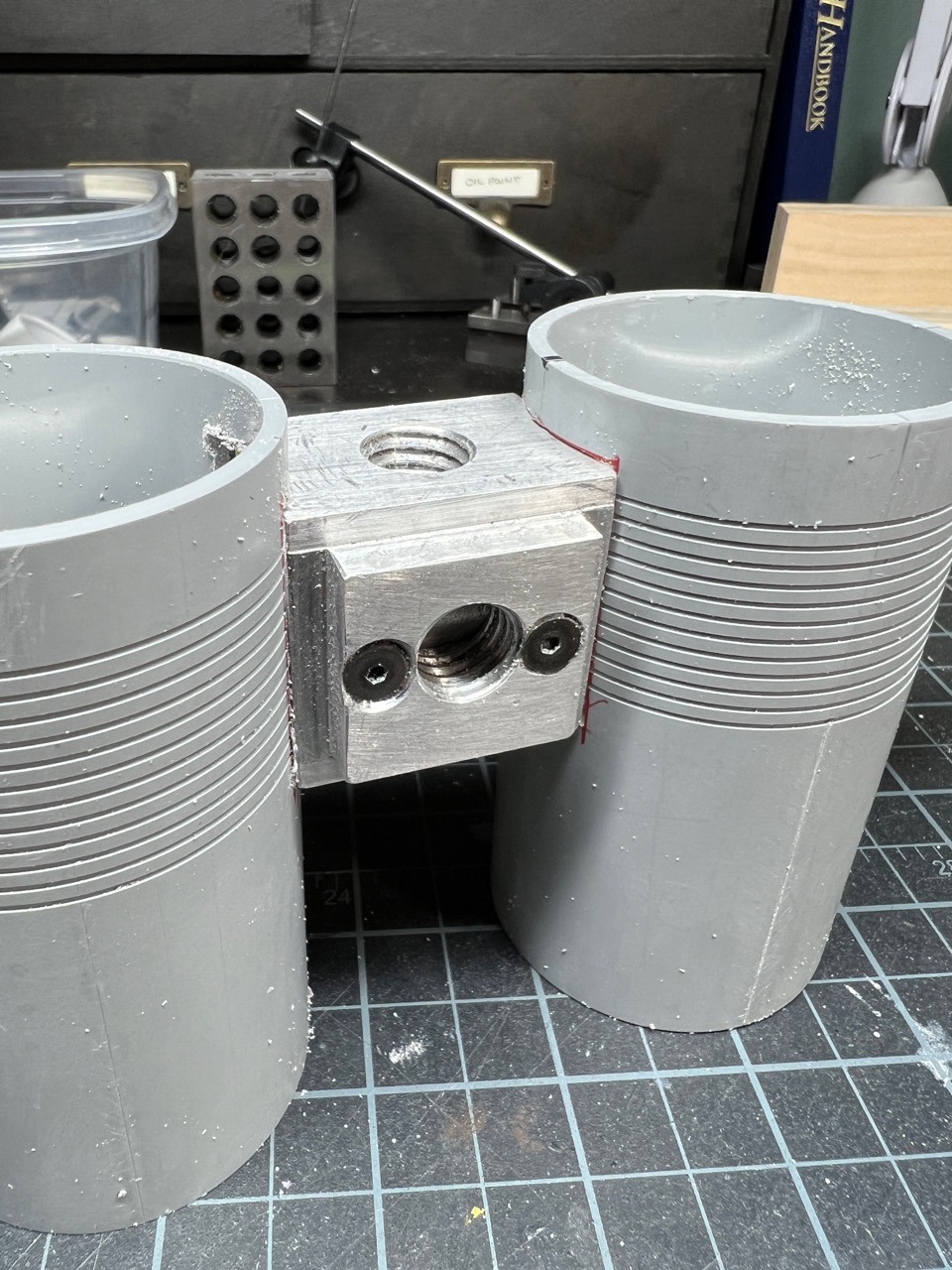

After a little clean up I gave them a test fit and I couldn't be happier with the results.

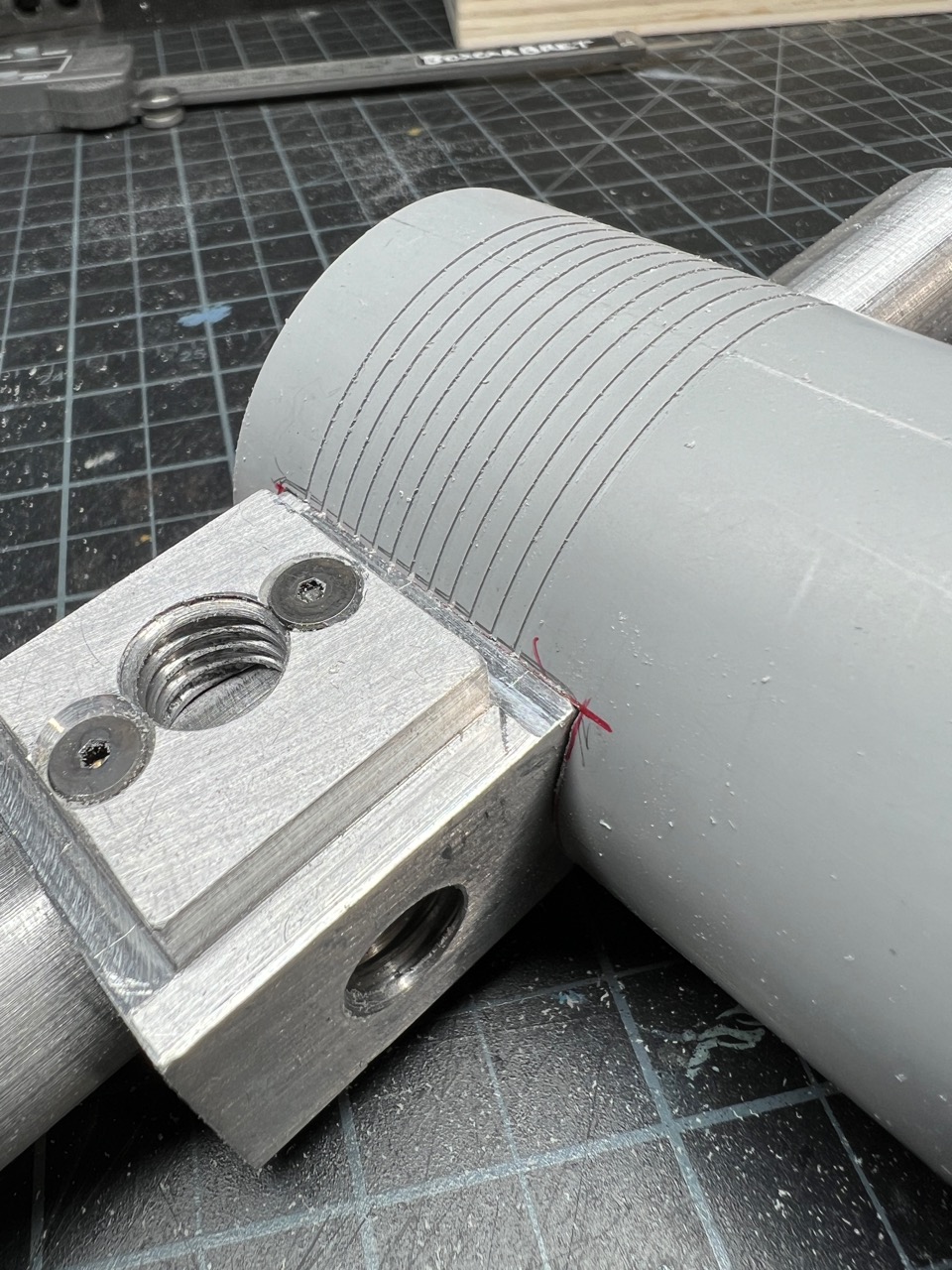

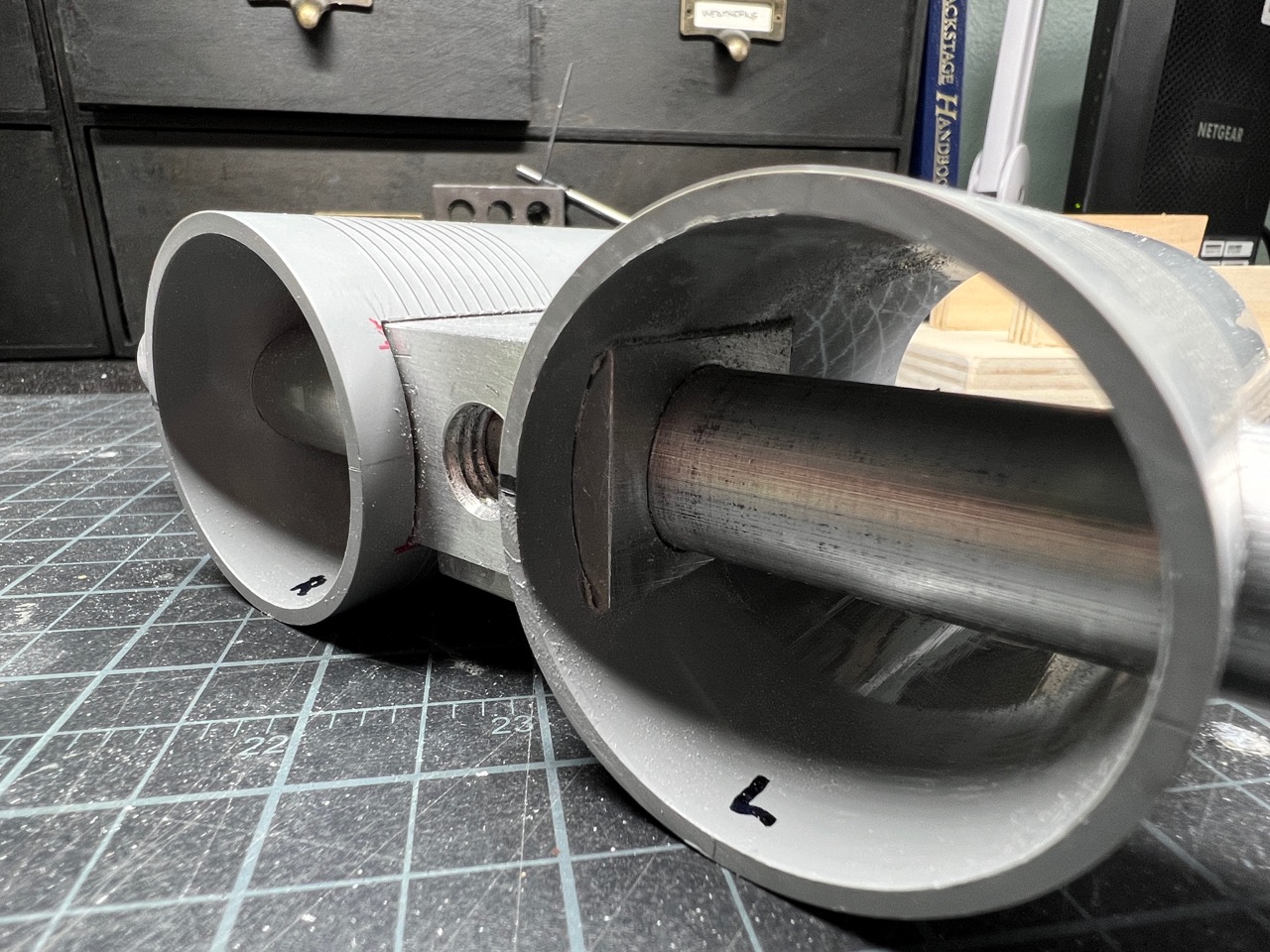

The next part was awkward but if anyone has a better idea please share it. With the body tubes aligned I traced the shape of the mounting block onto them.

This was done accurate as possible with the understanding that I would "sneak up" on the fit. Once I had the openings drawn out I cut them out using a Dremel being careful to get close but not too close to the markings.

I proceeded to clean up the openings using a combination of 100 and 150 grit sanding sticks and files trying as hard as possible to keep the everything square and the edges sharp. By going slow and testing the fit as I went it started to fit.

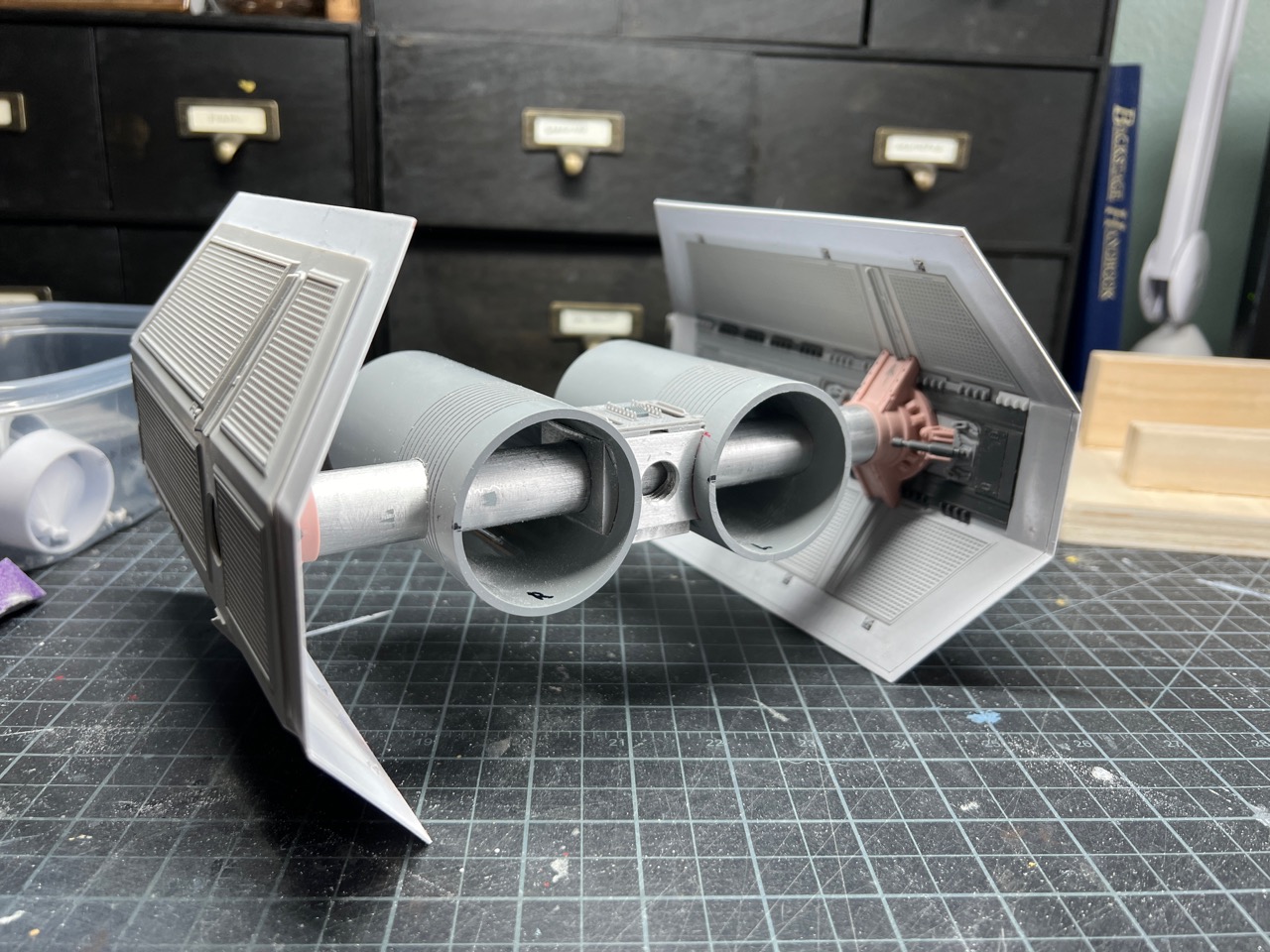

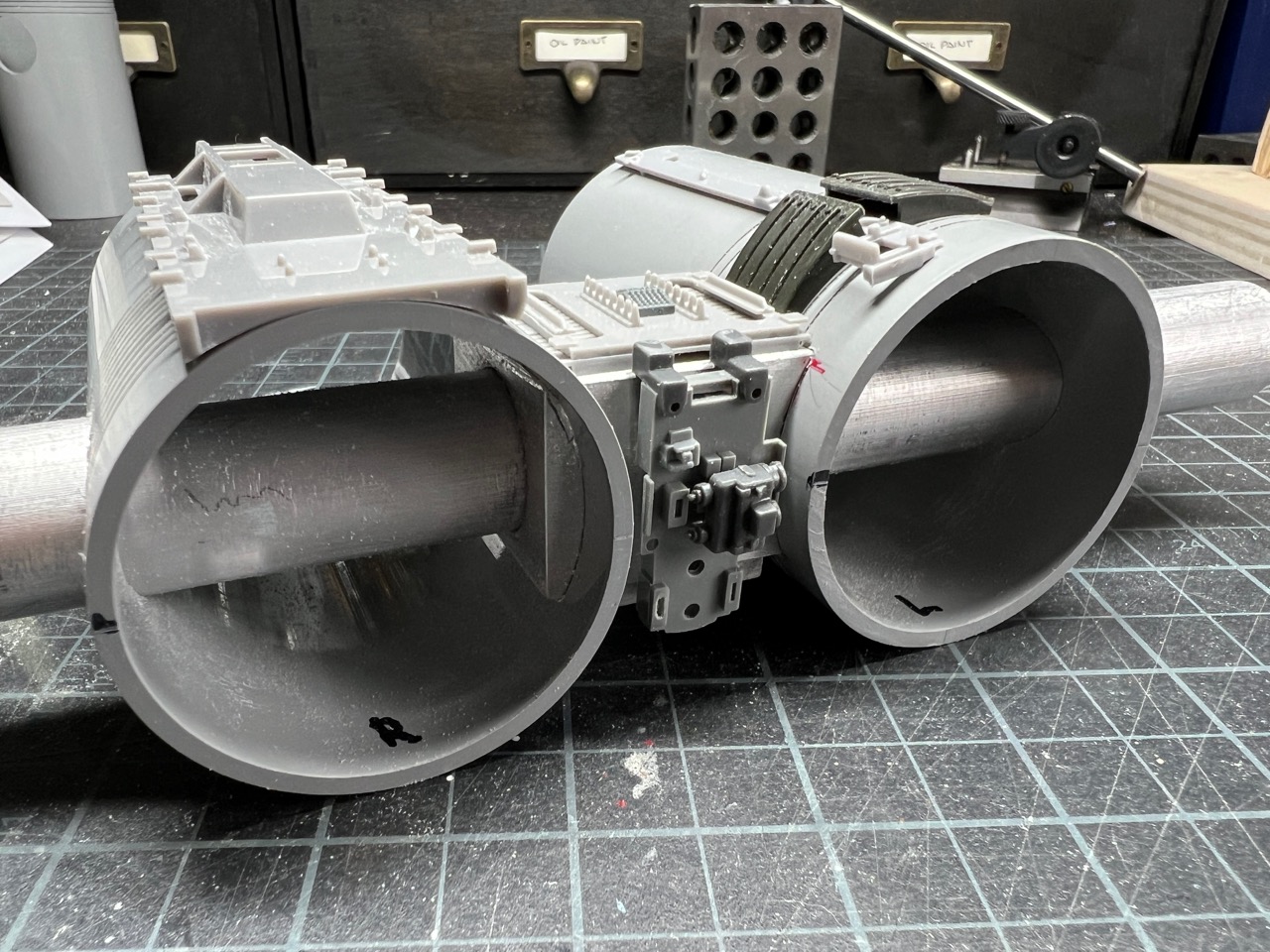

Before I knew it it was starting to look like a TIE bomber!

A little fine tuning and I was there.

What better way to celebrate and to motivate myself than to dry fit some parts to preview what's ahead.

Next up? The dreaded scribing.

Work that body! Work that body! With the wings in a reasonable state of completion it was starting to look like a Star War.

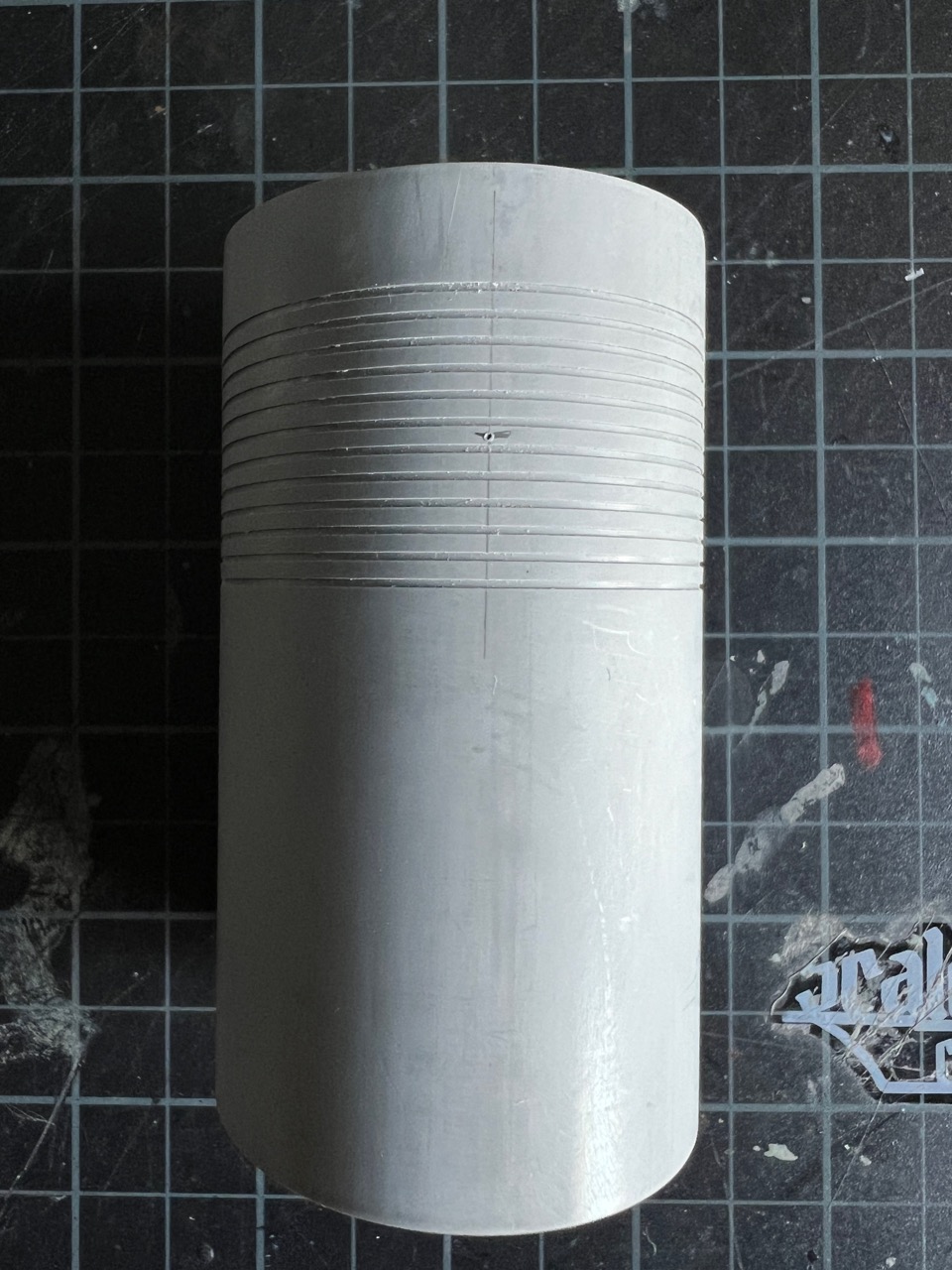

It was time to measure out and cut the openings in the body tubes for the armature.

The plan was to drill the holes for the round pipe to pass through both sides and then open up the inward facing sides to accommodate the mounting block. I started by finding the center and marking it with scribe.

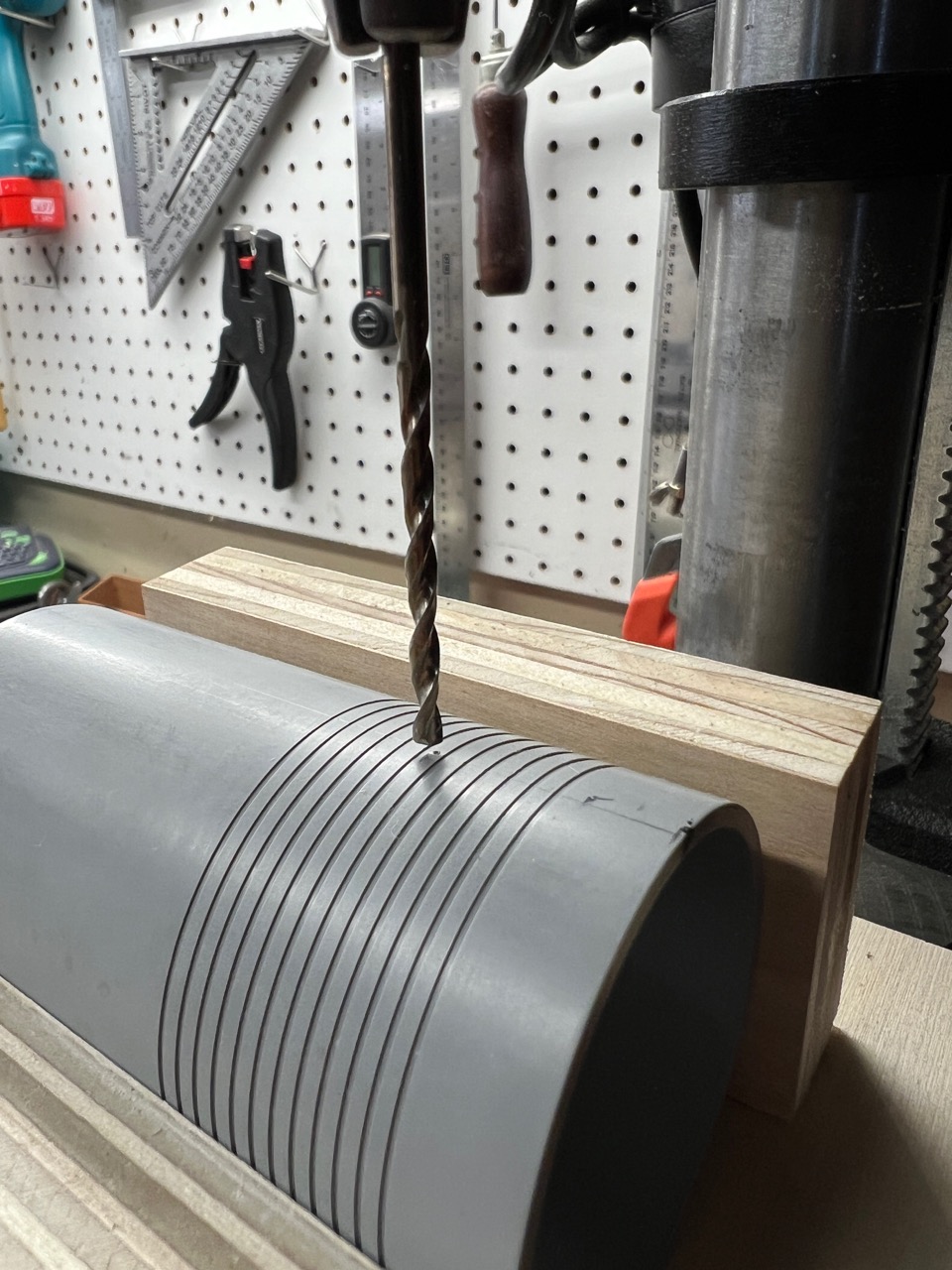

I then took it to the drill press to drill a 1/8" pilot hole.

Once the pilot hole was drilled I switched to a step bit to open up the hole. My step bits are from Horror Freight so they're not quite .75" but actually worked in my favor because it made for a nice snug fit.

After a little clean up I gave them a test fit and I couldn't be happier with the results.

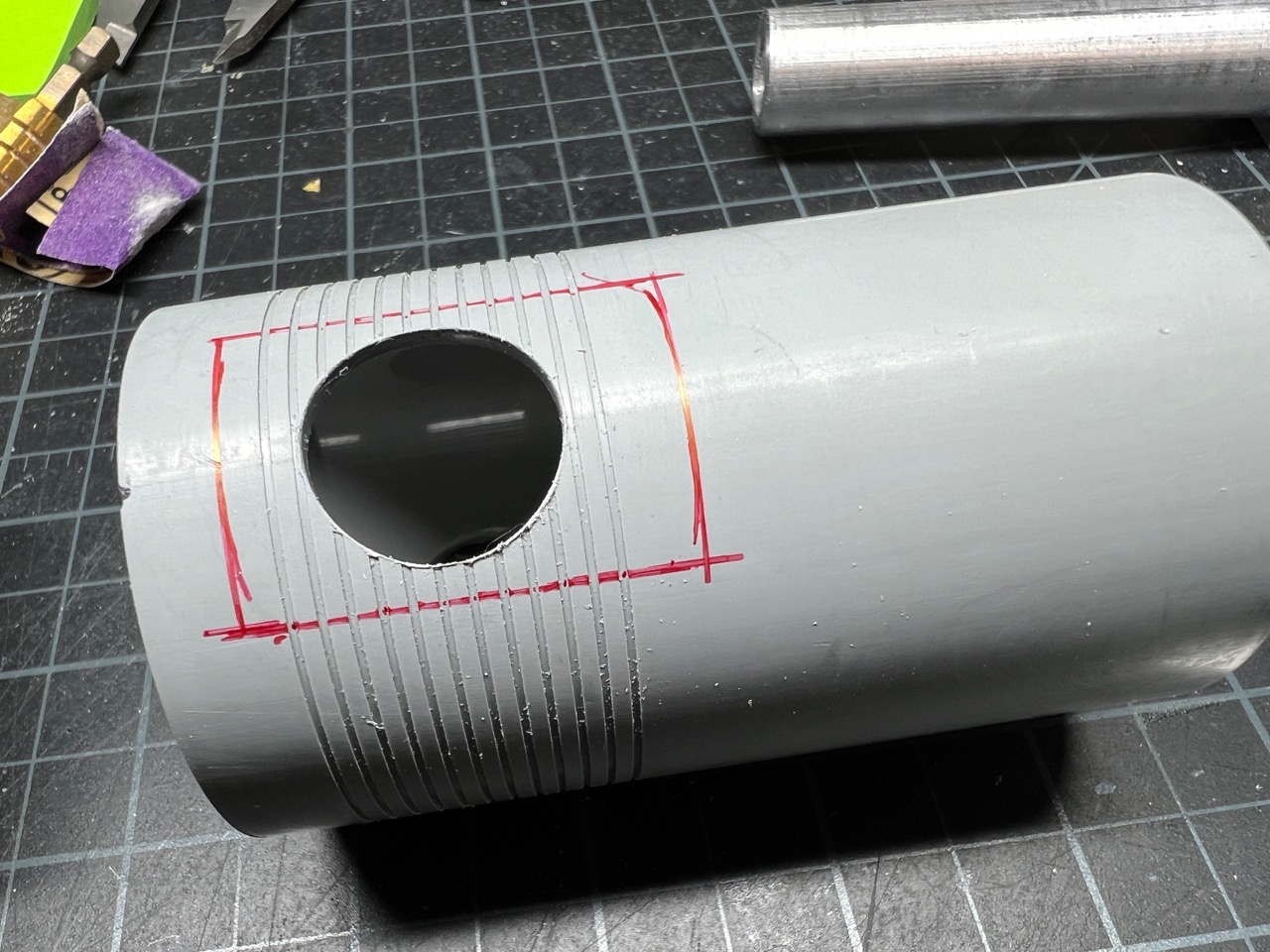

The next part was awkward but if anyone has a better idea please share it. With the body tubes aligned I traced the shape of the mounting block onto them.

This was done accurate as possible with the understanding that I would "sneak up" on the fit. Once I had the openings drawn out I cut them out using a Dremel being careful to get close but not too close to the markings.

I proceeded to clean up the openings using a combination of 100 and 150 grit sanding sticks and files trying as hard as possible to keep the everything square and the edges sharp. By going slow and testing the fit as I went it started to fit.

Before I knew it it was starting to look like a TIE bomber!

A little fine tuning and I was there.

What better way to celebrate and to motivate myself than to dry fit some parts to preview what's ahead.

Next up? The dreaded scribing.

Last edited:

They secure the mounting block to the rod.Looks like your plans worked well.

What are the two screws for in the armature?

bwayne64

Master Member

May 5, 2024

Work that body! Work that body! With the wings in a reasonable state of completion it was starting to look like a Star War.

View attachment 1820941

It was time to measure out and cut the openings in the body tubes for the armature.

The plan was to drill the holes for the round pipe to pass through both sides and then open up the inward facing sides to accommodate the mounting block. I started by finding the center and marking it with scribe.

View attachment 1820942

I then took it to the drill press to drill a 1/8" pilot hole.

View attachment 1820943

Once the pilot hole was drilled I switched to a step bit to open up the hole. My step bits are from Horror Freight so they're not quite .75" but actually worked in my favor because it made for a nice snug fit.

View attachment 1820948

View attachment 1820949

View attachment 1820950

After a little clean up I gave them a test fit and I couldn't be happier with the results.

View attachment 1820951

View attachment 1820952

The next part was awkward but if anyone has a better idea please share it. With the body tubes aligned I traced the shape of the mounting block onto them.

View attachment 1820953

View attachment 1820954

This was done accurate as possible with the understanding that I would "sneak up" on the fit. Once I had the openings drawn out I cut them out using a Dremel being careful to get close but not too close to the markings.

View attachment 1820955

I proceeded to clean up the openings using a combination of 100 and 150 grit sanding sticks and files trying as hard as possible to keep the everything square and the edges sharp. By going slow and testing the fit as I went it started to fit.

View attachment 1820956

View attachment 1820957

View attachment 1820958

Before I knew it it was starting to look like a TIE bomber!

View attachment 1820963

A little fine tuning and I was there.

View attachment 1820959

View attachment 1820962

View attachment 1820966

View attachment 1820967

View attachment 1820968

View attachment 1820965

What better way to celebrate and to motivate myself than to dry fit some parts to preview what's ahead.

View attachment 1820969

Next up? The dreaded scribing.

Thanks, Man! It’s been a fun and challenging build for me.Fantastic work! Following along intently, as I’ve started gathering up these kits to have my own go at this studio scale model. Keep up the good work!

Similar threads

- Replies

- 3

- Views

- 764

- Replies

- 8

- Views

- 928