Carlb

Well-Known Member

Hello all, welcome to a scratch build of a "concept art" spaceship model.

I didn't want to recreate anything from a movie, television series or video game, so I looked at as much concept art as I could find. To make the project a bit easier on myself, I deliberately searched for a vessel that had few, if any, curves or rounded body shapes.

The one I chose was designed by artist Paolo Puggioni. This is the only angle of his ship on-line, so everything out of view must be created from my imagination. I propose this to be a science and research vessel, with a multitude of sensors for planetary survey. Like the drawing, the paint scheme will be all white, and since it stays in space and never enters hostile atmosphere, will have very minor weathering. Any warfare on this kind of vessel would be illogical, so the guns are quite small.

It will be named after my favorite character in Sci-fi.... from Star Trek The Original Series. Therefore, it will be known as...United Federation of Planets Research Vessel Montgomery Scott. (Scotty).

I actually met James Doohan back in the mid 90's, when I was an engineer at a studio shooting a TV commercial. I walked into a (what I thought was an unoccupied) dressing room, and Mr. Doohan was in the middle of changing clothes! We exchanged a few pleasant sentences... and I quickly escaped.

For details on this model, I will be using most of the concept drawing as a guideline, but invent the rest. Note: I do not own a 3d printer, laser, lathe or CNC unit, so this will be 99% hand built.

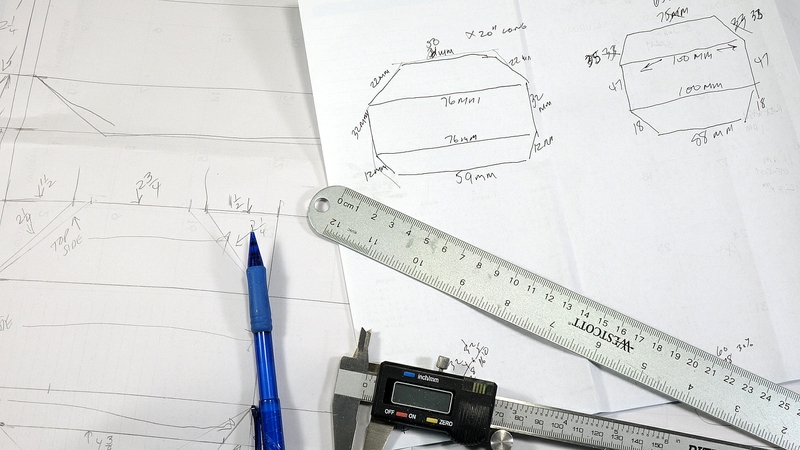

I always need a mockup first, so to get moving, I estimated some preliminary dimensions. Due to workspace and storage limitations, I can only manage a model with a maximum of approximately 24 inches (609mm). Even though I live in the US, I mostly work with metric numbers. As far as a definitive "scale", I have no idea.

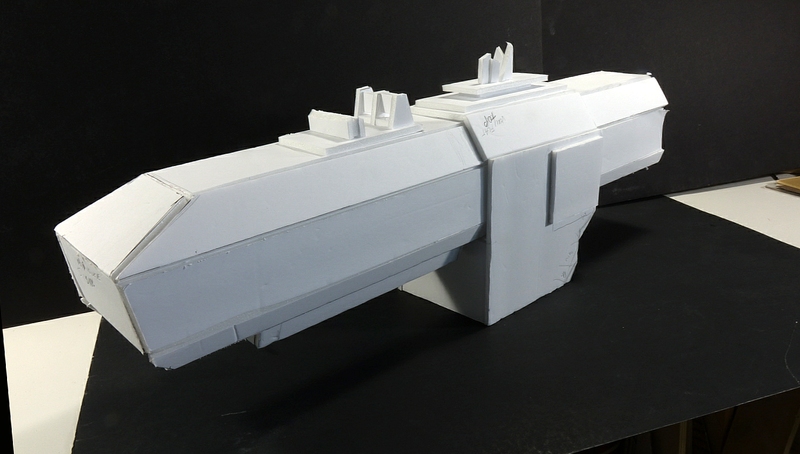

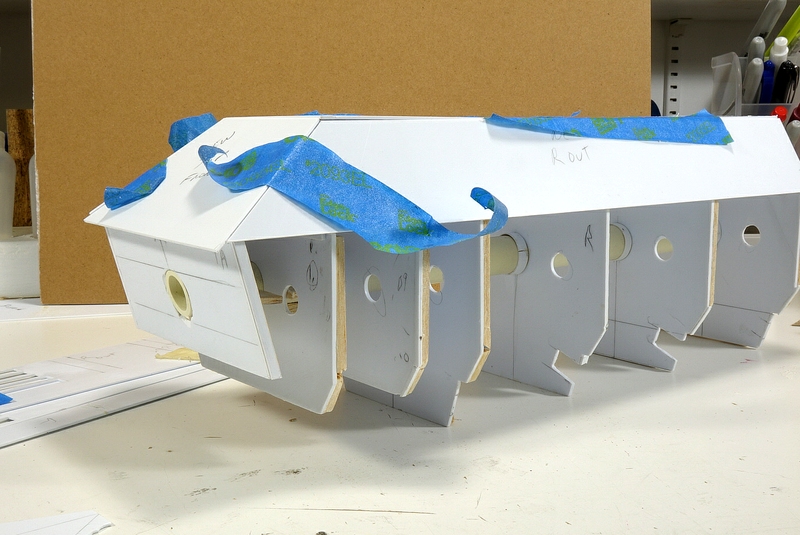

This is the 3rd version of a mock up I built out of white foam core board. The first was too big, the 2nd too small, and this one is in-between..

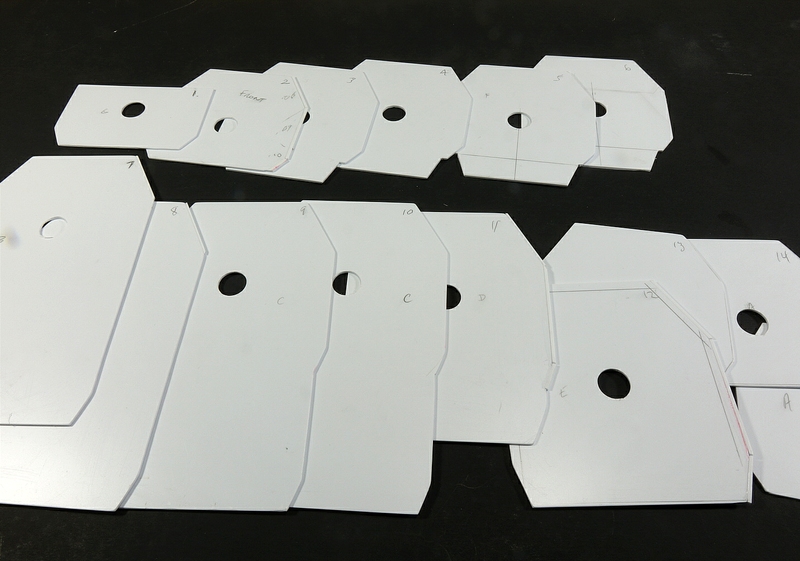

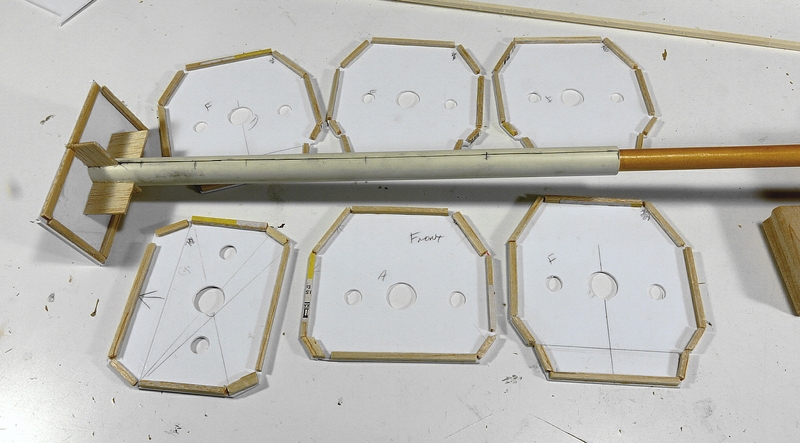

To create the hexagon carcass, I chose .06" (1.5mm) styrene bulkheads, making card templates first to check sizes, then transferred that to the styrene.

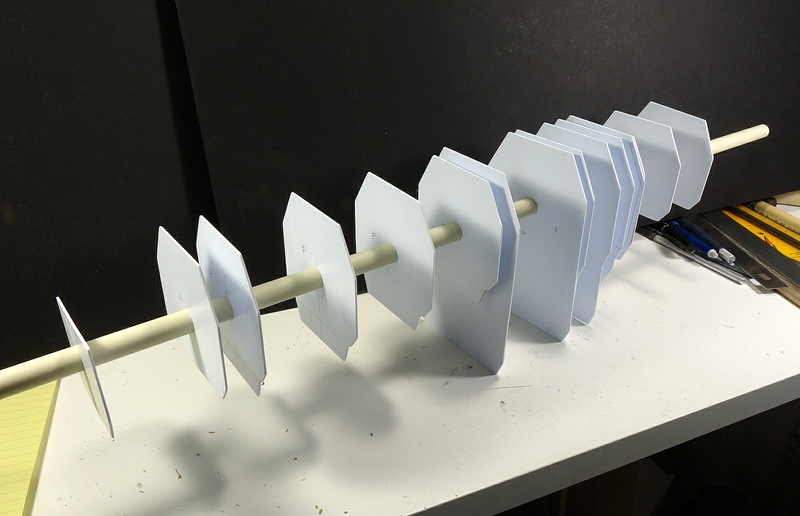

These will be anchored to this CVPC 1/2" (12.7mm) pipe for the inner core spine.

This model will be lit with LED's, so I drilled extra holes thru each bulkhead for wiring..

The CPVC (ID .468"or 11.89mm) pipe will slide over a wood dowel of a bit smaller diameter .460." (11.68mm), since I plan to build the model in 3 separate sections, front, middle and back. Then slide them together as the final step of the build. I may change the wood dowel to a metal pipe/rod depending on the weight of the finished model.

I lined the perimeter of the bulkheads with balsa wood for additional gluing surface.

The bow section is being test fitted with styrene sheet.

After looking at the "nose" for a while, I decided it just wasn't steep enough pitch, as in the drawing. Chopped it down and made new parts. Looking better. Nothing glued.

I hope to update this build 3 or 4 times a month, and it will NOT be abandoned until its finished.

Thanks for following.

Till next time...

I didn't want to recreate anything from a movie, television series or video game, so I looked at as much concept art as I could find. To make the project a bit easier on myself, I deliberately searched for a vessel that had few, if any, curves or rounded body shapes.

The one I chose was designed by artist Paolo Puggioni. This is the only angle of his ship on-line, so everything out of view must be created from my imagination. I propose this to be a science and research vessel, with a multitude of sensors for planetary survey. Like the drawing, the paint scheme will be all white, and since it stays in space and never enters hostile atmosphere, will have very minor weathering. Any warfare on this kind of vessel would be illogical, so the guns are quite small.

It will be named after my favorite character in Sci-fi.... from Star Trek The Original Series. Therefore, it will be known as...United Federation of Planets Research Vessel Montgomery Scott. (Scotty).

I actually met James Doohan back in the mid 90's, when I was an engineer at a studio shooting a TV commercial. I walked into a (what I thought was an unoccupied) dressing room, and Mr. Doohan was in the middle of changing clothes! We exchanged a few pleasant sentences... and I quickly escaped.

For details on this model, I will be using most of the concept drawing as a guideline, but invent the rest. Note: I do not own a 3d printer, laser, lathe or CNC unit, so this will be 99% hand built.

I always need a mockup first, so to get moving, I estimated some preliminary dimensions. Due to workspace and storage limitations, I can only manage a model with a maximum of approximately 24 inches (609mm). Even though I live in the US, I mostly work with metric numbers. As far as a definitive "scale", I have no idea.

This is the 3rd version of a mock up I built out of white foam core board. The first was too big, the 2nd too small, and this one is in-between..

To create the hexagon carcass, I chose .06" (1.5mm) styrene bulkheads, making card templates first to check sizes, then transferred that to the styrene.

These will be anchored to this CVPC 1/2" (12.7mm) pipe for the inner core spine.

This model will be lit with LED's, so I drilled extra holes thru each bulkhead for wiring..

The CPVC (ID .468"or 11.89mm) pipe will slide over a wood dowel of a bit smaller diameter .460." (11.68mm), since I plan to build the model in 3 separate sections, front, middle and back. Then slide them together as the final step of the build. I may change the wood dowel to a metal pipe/rod depending on the weight of the finished model.

I lined the perimeter of the bulkheads with balsa wood for additional gluing surface.

The bow section is being test fitted with styrene sheet.

After looking at the "nose" for a while, I decided it just wasn't steep enough pitch, as in the drawing. Chopped it down and made new parts. Looking better. Nothing glued.

I hope to update this build 3 or 4 times a month, and it will NOT be abandoned until its finished.

Thanks for following.

Till next time...