You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Studio Scale Tyrell Pyramid

- Thread starter Pyramidrep

- Start date

Pyramidrep

Sr Member

Searun,

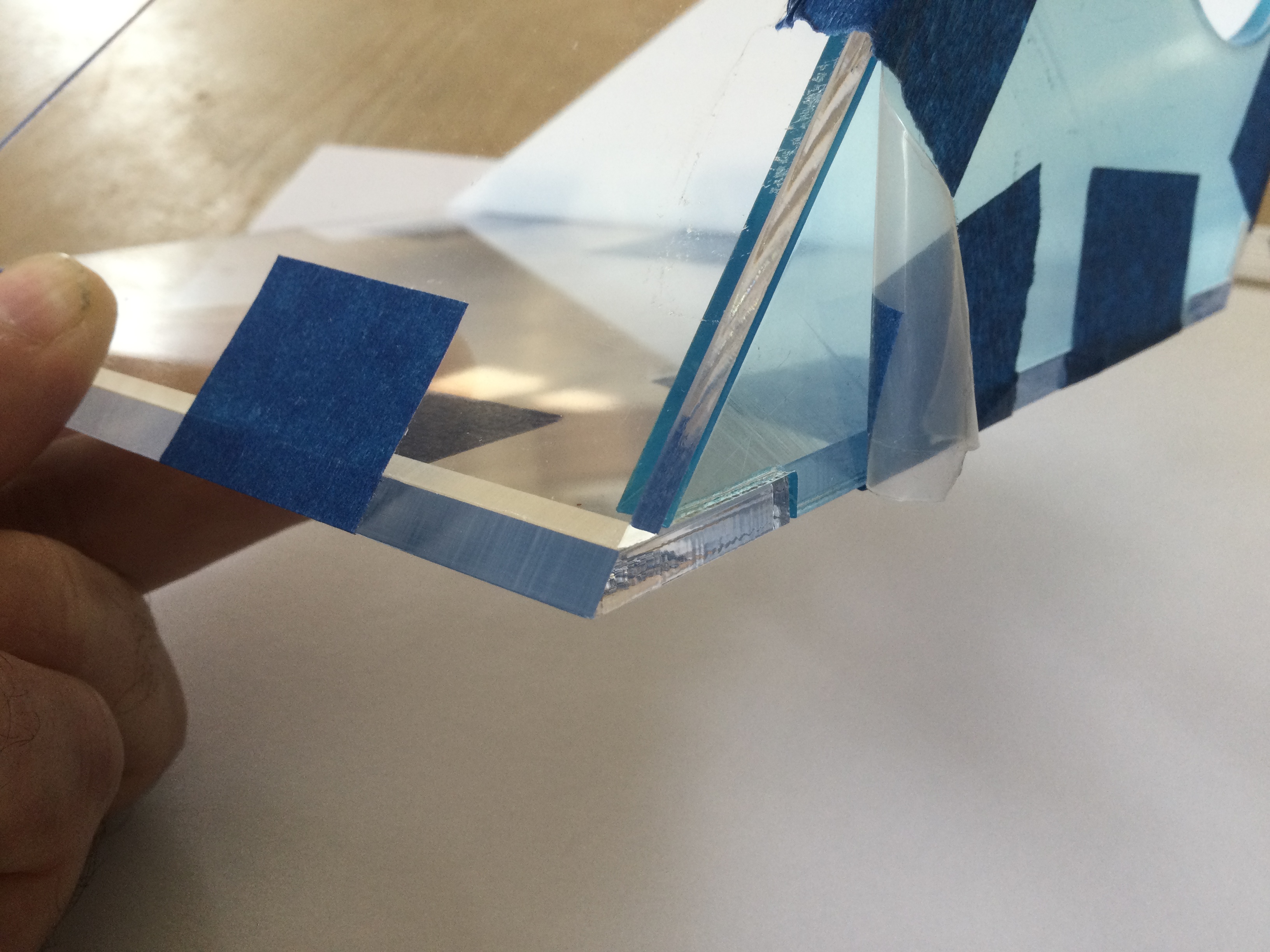

They are the result of a lot of trial and error. I eventually found a great guy who worked and guided me with all the little issues. It’s not a cheap process but cutting acrylic on a table saw, quite apart from the danger element, is a pain. Just to get here at this point - testing mock-ups, preparing drawings for cutting - its a lot of time. But this is at a level of accuracy that would have been impossible in 1981/2.

Have been looking at StudioKitbashs Falcon Thread - I can see his journey with acrylic parts - not easy and his build is more complicated and expensive with those domes.

As regards the background music, I have an unusual taste in music and I’m more likely to be listening to modern neoclassical stuff - Olafar Arnalds, Johann Johannson, Max Richter. Favourite Steve Reich’s “ Music for 18 musicians”. Put it on and let it drown over you- you find you’re not even listening to it most of the time and can concentrate on your work.

They are the result of a lot of trial and error. I eventually found a great guy who worked and guided me with all the little issues. It’s not a cheap process but cutting acrylic on a table saw, quite apart from the danger element, is a pain. Just to get here at this point - testing mock-ups, preparing drawings for cutting - its a lot of time. But this is at a level of accuracy that would have been impossible in 1981/2.

Have been looking at StudioKitbashs Falcon Thread - I can see his journey with acrylic parts - not easy and his build is more complicated and expensive with those domes.

As regards the background music, I have an unusual taste in music and I’m more likely to be listening to modern neoclassical stuff - Olafar Arnalds, Johann Johannson, Max Richter. Favourite Steve Reich’s “ Music for 18 musicians”. Put it on and let it drown over you- you find you’re not even listening to it most of the time and can concentrate on your work.

Last edited:

Pyramidrep

Sr Member

I just wanted to touch on the subject of producing PHOTOETCH parts. I got asked quite a lot by various people over the past 2 years and have been asked again by one of the members here.

1.You have 2 choices to have the stuff produced. - either engage a Photoetch Company or try to do the homemade method ( not recommended) with highly dangerous and toxic chemicals . Unless you have experience with the latter method, pay a recognised & experienced company to do it. “You health is your wealth” as they say.

2. Cost - Yes. It can be expensive. Tooling for the design is a seperate cost, quantity & type of the sheet material ( brass , stainless steel), postage, Vat, import charges etc.

I haven’t recently looked at the costs in detail but since Brexit, the war in Ukraine and big increases in inflation in the past few years, i imagine costs have increased significantly since I had mine made in 2020. I have another finished pattern to be done in a few months time am expecting the cost to be comparatively high.

3. Producing the vector based drawing. You will need CAD software and also a photo-editing program like photoshop. There are some programs free ( with some limited features) available to hobbyists and college students. Google online to find those yourselves. Alternatively buy a licence / subscription for a year or enough time to produce the pattern.

With regard Photoshop, most images of the original design patterns online need some adjustment because of photographic distortion. You’ll see this by checking with guide rulers in your program.

These programs can be very quickly learned through college courses, online tutorials. So don’t be afraid of learning to use them. And remember you dont need to know every feature of these programs - just enough to do the job you want.

4. Drawing the complex patterns take time…… a lot of time. So be patient.

That main etch pattern I drew for the Buttresses took approximately 200 to 250 hours work - over the space of a year.

So when you patience runs thin, take a break, go for a walk, a cycle, on holidays or for a drink with family and friends and remind yourself it’s a hobby project.

5. Finally I don’t sell any CAD work on artwork/ material I do not own copyright on.

I may on occasion trade certain PRINTED drawings in return for material that will assist in my research on Tyrell Pyramid.

Hope that is some help.

1.You have 2 choices to have the stuff produced. - either engage a Photoetch Company or try to do the homemade method ( not recommended) with highly dangerous and toxic chemicals . Unless you have experience with the latter method, pay a recognised & experienced company to do it. “You health is your wealth” as they say.

2. Cost - Yes. It can be expensive. Tooling for the design is a seperate cost, quantity & type of the sheet material ( brass , stainless steel), postage, Vat, import charges etc.

I haven’t recently looked at the costs in detail but since Brexit, the war in Ukraine and big increases in inflation in the past few years, i imagine costs have increased significantly since I had mine made in 2020. I have another finished pattern to be done in a few months time am expecting the cost to be comparatively high.

3. Producing the vector based drawing. You will need CAD software and also a photo-editing program like photoshop. There are some programs free ( with some limited features) available to hobbyists and college students. Google online to find those yourselves. Alternatively buy a licence / subscription for a year or enough time to produce the pattern.

With regard Photoshop, most images of the original design patterns online need some adjustment because of photographic distortion. You’ll see this by checking with guide rulers in your program.

These programs can be very quickly learned through college courses, online tutorials. So don’t be afraid of learning to use them. And remember you dont need to know every feature of these programs - just enough to do the job you want.

4. Drawing the complex patterns take time…… a lot of time. So be patient.

That main etch pattern I drew for the Buttresses took approximately 200 to 250 hours work - over the space of a year.

So when you patience runs thin, take a break, go for a walk, a cycle, on holidays or for a drink with family and friends and remind yourself it’s a hobby project.

5. Finally I don’t sell any CAD work on artwork/ material I do not own copyright on.

I may on occasion trade certain PRINTED drawings in return for material that will assist in my research on Tyrell Pyramid.

Hope that is some help.

Last edited:

Pyramidrep

Sr Member

If you are as inexperienced with Studio Scale model making as I still am, one of the things you quickly learn is to accept the stuff that constantly goes wrong. Router packed it in last week so waiting for new one & mount plate to be delivered. The buttress has a number of specific angled cuts that need to be made on acrylic. The last time I got away with cutting them on a table saw ( not fully accurate). This time it will be done with a number of jigs attached to a router table.

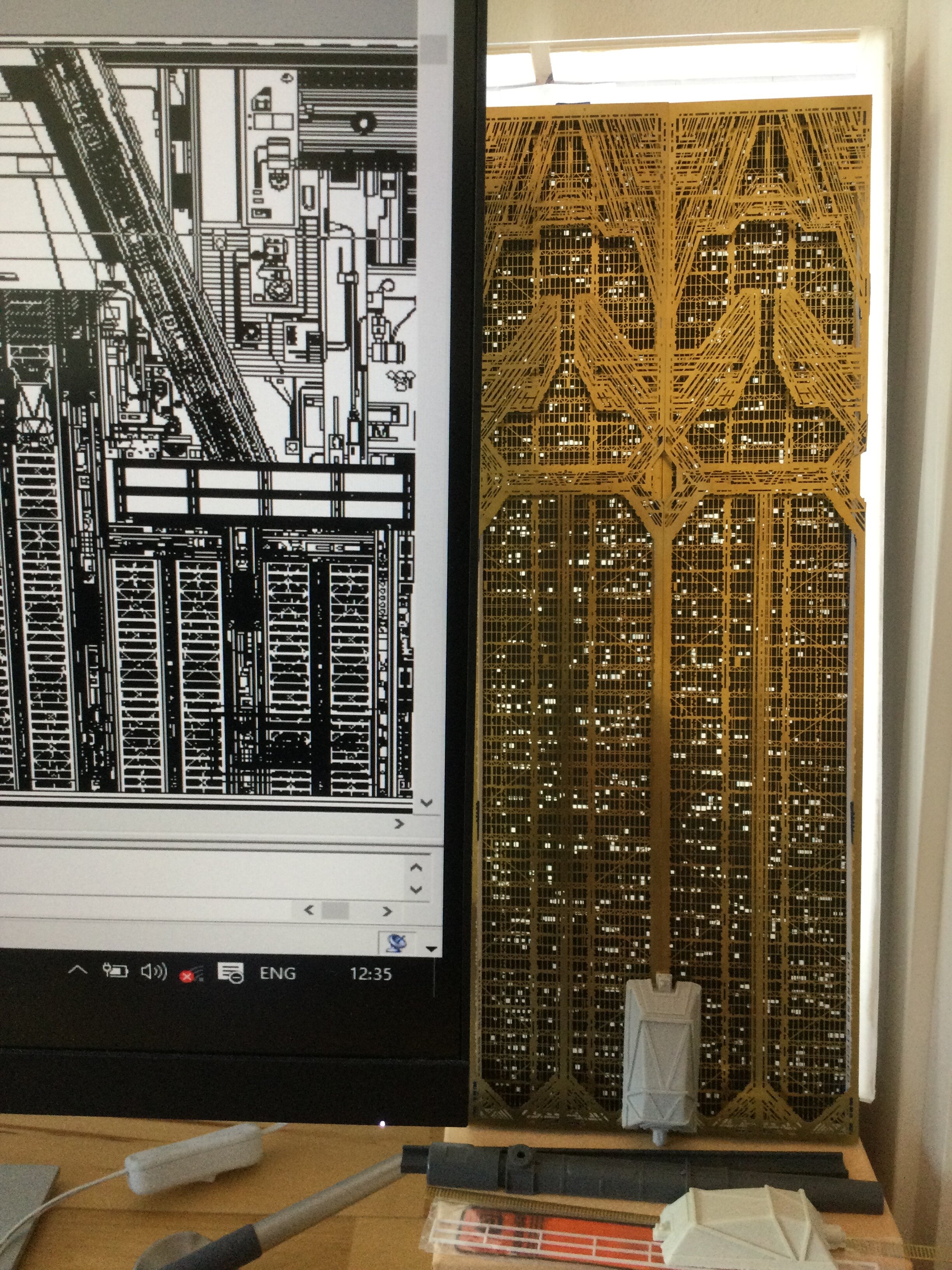

I have a long list of other tasks to finish so I try to deal with some small areas with the few hours each week I get to work on this project. Today I made some revision to the Close Up section research and I can still some areas that need correction .

Image below is a test of a revised section of the Buttress lighting pattern in order to check and see how it looks. This time I varied the light sizes and added a little colour to some edges. Looks better but still feel needs further work.

I have a long list of other tasks to finish so I try to deal with some small areas with the few hours each week I get to work on this project. Today I made some revision to the Close Up section research and I can still some areas that need correction .

Image below is a test of a revised section of the Buttress lighting pattern in order to check and see how it looks. This time I varied the light sizes and added a little colour to some edges. Looks better but still feel needs further work.

Last edited:

Pyramidrep

Sr Member

God, seems like I haven’t been here in ages and have a lot of catching up to do, now my wife has been appeased with house decorating , our travelling abroad, work and all the life stuff.

So last time I was here I mentioned the difficulty in cutting acrylic. I bought a new router and built a small router table and a number of jigs to cut the various angles ( all calculated in cad). I managed to bevel / cut most of the pieces and still have a few small pieces left to do. And it’s works pretty well ( after a lot of practice on scrap acrylic). I also found a company here in Ireland that sells Weld- on solvent adhesive for acrylic to keep the acrylic clear when gluing together. Super glue had a tendency to fog and while it’s not a big issue because the acrylic is being covered, it’s better to keep it as clear as possible.

The router table was made with floorboards ripped on a table saw and some mdf. All the various angled jigs are similar to the image above with cutter head in the centre.

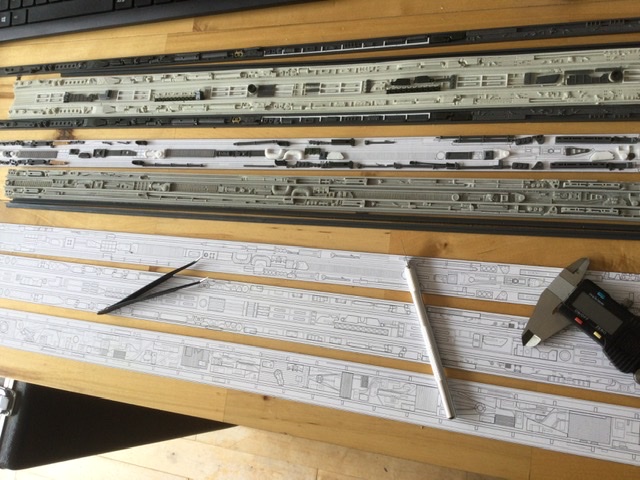

In my last post here, I had mentioned I was working on the the Close - Up section as well. I found some of final missing pieces on the front facade.( only two small pieces to trace). I knew there were small errors compounded in research so as I’ve looked with the physical parts, I found the copies of resin casting detail strips have shrunk by approx. 20mm. and that all these longer detail strips/ patterns are the same length ( approx. 27”).

May not look much, some very important finds, the grey parts a really important find after a long, frustrating search because they are on the the facade and the roof of the 8 foot model.

So, the build continues……

So last time I was here I mentioned the difficulty in cutting acrylic. I bought a new router and built a small router table and a number of jigs to cut the various angles ( all calculated in cad). I managed to bevel / cut most of the pieces and still have a few small pieces left to do. And it’s works pretty well ( after a lot of practice on scrap acrylic). I also found a company here in Ireland that sells Weld- on solvent adhesive for acrylic to keep the acrylic clear when gluing together. Super glue had a tendency to fog and while it’s not a big issue because the acrylic is being covered, it’s better to keep it as clear as possible.

The router table was made with floorboards ripped on a table saw and some mdf. All the various angled jigs are similar to the image above with cutter head in the centre.

In my last post here, I had mentioned I was working on the the Close - Up section as well. I found some of final missing pieces on the front facade.( only two small pieces to trace). I knew there were small errors compounded in research so as I’ve looked with the physical parts, I found the copies of resin casting detail strips have shrunk by approx. 20mm. and that all these longer detail strips/ patterns are the same length ( approx. 27”).

May not look much, some very important finds, the grey parts a really important find after a long, frustrating search because they are on the the facade and the roof of the 8 foot model.

So, the build continues……

Pyramidrep

Sr Member

PITA is the best description for it. Can look beautiful but just nasty stuff to work with. I have to haul the set-up out to the garden when it’s not raining here, protective mask on because the chips fly everwhere even with a vacuum attachment.…………….to cut that PITA acrylic

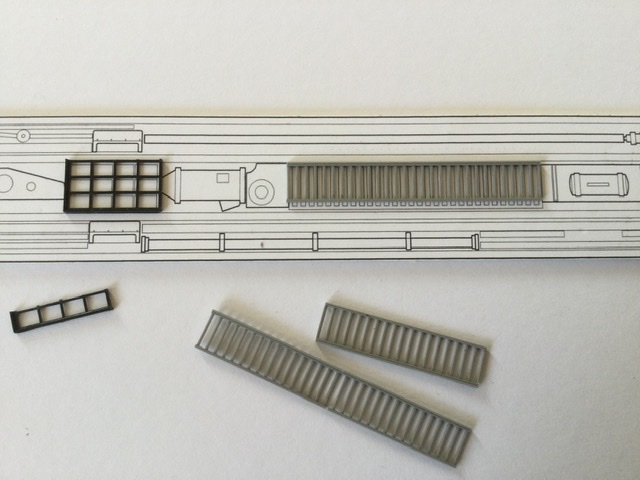

Here’s another really great discovery recently from the detail on the garage roof of the Close- Up and also used in a few other places. That was a good day.

Looking good!!

Solvent is always best with acrylic. The super glue's exo-thermic cure adds stress to the acrylic and can cause crazing or cracking over time.

It is best to have the parts lined up and ready for assembly and then do one thorough pass with the solvent. As you stated, interior parts are fine with superglue.

Solvent is always best with acrylic. The super glue's exo-thermic cure adds stress to the acrylic and can cause crazing or cracking over time.

It is best to have the parts lined up and ready for assembly and then do one thorough pass with the solvent. As you stated, interior parts are fine with superglue.

Last edited:

M9000

New Member

Hi, can you share the images of the Tyrell building, please ?Hi everyone. So the etching company in the UK informed me a few days ago that production is halted because of the COVID-19 crisis, it will be some time before this aspect of the build can be sorted. I’ve also been told that the company laser cutting the acrylic sheet for me has also closed. Anyhow, this is to be expected. Attached are images of the some drawings I did for the etch. The larger is my version of the original master. It measures 12x24 inches. The tolerance for the minimum line thickness is 0.5mm In order to be etched cleanly. Which meant I had to modify and adapt some areas of the original detail. This might explain why you see original etched parts looking a bit rough, where lines very obviously blow out. The two drawing on the right are the ones going to etch. One at full scale and the other at half scale.

M9000

New Member

Hi, can you share the images of the Tyrell building, please ?Hi everyone. So the etching company in the UK informed me a few days ago that production is halted because of the COVID-19 crisis, it will be some time before this aspect of the build can be sorted. I’ve also been told that the company laser cutting the acrylic sheet for me has also closed. Anyhow, this is to be expected. Attached are images of the some drawings I did for the etch. The larger is my version of the original master. It measures 12x24 inches. The tolerance for the minimum line thickness is 0.5mm In order to be etched cleanly. Which meant I had to modify and adapt some areas of the original detail. This might explain why you see original etched parts looking a bit rough, where lines very obviously blow out. The two drawing on the right are the ones going to etch. One at full scale and the other at half scale.

Pyramidrep

Sr Member

I am not sure which images you are specifically referring to.?Hi, can you share the images of the Tyrell building, please ?

M9000

New Member

I mean the design of the building, I would like to try something and make something with my laserI am not sure which images you are specifically referring to.?

Pyramidrep

Sr Member

Still unsure about your question. If it’s the etch patterns you’re looking for , I am afraid I won’t be sharing that work with anyone. It‘s not for sale either. You will have to do the work yourself to draw those.I mean the design of the building, I would like to try something and make something with my laser

Last edited:

Pyramidrep

Sr Member

Ok. You are new to the forum here.yes I mean the pattern of the building, the stuff you etched, why would you not share it ? Where did you find it ?

I don’t know you.

It’s common courtesy for any to introduce yourself when meeting and greeting people you dont know.

Being on the forum here and posting on the different subject matter is entirely voluntary by the members here.

What we chose to share and not share is up to each member.

Be thankful that the members here so graciously post their work and research here week after week, month after month.

We are here to complete our “ loved” projects . If you, the reader/ viewer benefit from what is posted here, then good for you.

My primary interest is the Tyrell Pyramid.

What I choose to share or not share is entirely my decision.

If you cannot understand why I will not give a mountain of valuable work away to a stranger , well I won’t explain it to you.

That’s very naive.

Pyramidrep

Sr Member

I‘m feeling a bit like John McClane in Nakatomi Plaza Tower talking to the cop. “ Feeling pretty ….. unappreciated, Pal”. I think there might be an expletive in there somewhere….. best omit that one out!

M9000

New Member

I thought that was some stuff that was somehow scanned from the original production and can be found online, they own the copyright anyway. If you drawn it by yourself from the movie screenshots, that's great, If you don't want to give it to anyone I'm just sorry to hear that, I wanted to make a part of the pyramid for myself, the entire is just too large  I don't really have the time to draw it from the movie screenshots so if it can't be found online I have to abandon this project.

I don't really have the time to draw it from the movie screenshots so if it can't be found online I have to abandon this project.

Similar threads

- Replies

- 1

- Views

- 208