mung

Sr Member

Most of the outer surface detailing has now been done.

The black bits are 1mm styrene sheet.

There is still a few areas that may need a few bits added but I will spray a primer grey pass next to see where

it's at before deciding.

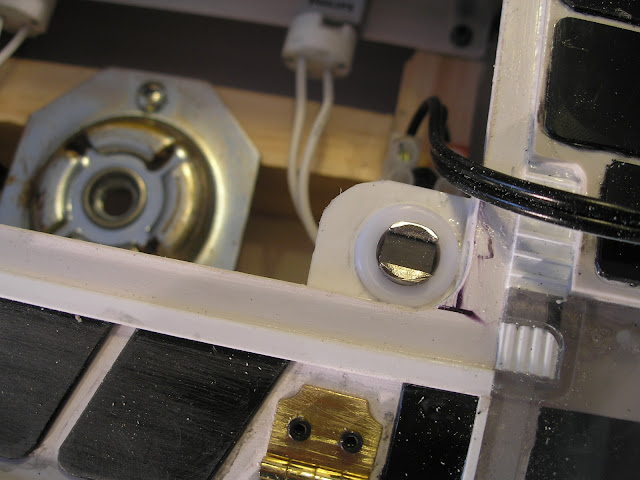

I also finished up the retaining system for both hatches.

The rear hatch has a plug that fills the hole for the support rod.

The hole for the support rod also acts as the handle to pull the hatch up and forward to release.

A couple of small round magnetic cabinet catches hold the hatch in place in each front corner.

The steel washers from the catches are superglued to the under side of the hatch. You first have to roughen

up the glued side with very coarse sandpaper so that the superglue can grip effectively, as well as allowing

some to squeeze up through the counter sunk screw hole.

A squirt of accelerator helps the super glue to harden quickly.

After stating here only a couple of posts ago I wasn't going to hinge the canopy hatch, I went out and purchased

a couple of tiny hinges and... hinged the hatch.

The hinges are superglued to the hatch and to the hull again roughening up the glued surface, and in addition

with a couple of m2 cap screws screwed in as part of the detail.

The front is held in place just by the friction fit of the acrylic window into the hole in the hull.

Some more positive closure may be required, we will see.

Next up is masking the windows, a grey primer pass and then starting the cockpit interior.

More soon...

The black bits are 1mm styrene sheet.

There is still a few areas that may need a few bits added but I will spray a primer grey pass next to see where

it's at before deciding.

I also finished up the retaining system for both hatches.

The rear hatch has a plug that fills the hole for the support rod.

The hole for the support rod also acts as the handle to pull the hatch up and forward to release.

A couple of small round magnetic cabinet catches hold the hatch in place in each front corner.

The steel washers from the catches are superglued to the under side of the hatch. You first have to roughen

up the glued side with very coarse sandpaper so that the superglue can grip effectively, as well as allowing

some to squeeze up through the counter sunk screw hole.

A squirt of accelerator helps the super glue to harden quickly.

The rear of the hatch is gripped by a long strip of plastic that hooks under the hull opening.

After stating here only a couple of posts ago I wasn't going to hinge the canopy hatch, I went out and purchased

a couple of tiny hinges and... hinged the hatch.

The hinges are superglued to the hatch and to the hull again roughening up the glued surface, and in addition

with a couple of m2 cap screws screwed in as part of the detail.

The front is held in place just by the friction fit of the acrylic window into the hole in the hull.

Some more positive closure may be required, we will see.

Next up is masking the windows, a grey primer pass and then starting the cockpit interior.

More soon...